SLUUCE8A February 2021 – October 2021 UCC25800-Q1

- Trademarks

- 1 Description

- 2 Electrical Performance Specifications

- 3 Schematic Diagram

- 4 Description - How to Use

- 5 Test Setup

-

6 Performance Data and Typical Characteristic Curves

- 6.1 Efficiency Result of the LLC Board with External DC Input Voltage

- 6.2 Efficiency Result of the LLC Board with Pre-regulator on Board

- 6.3 Efficiency Typical Results

- 6.4 Output Characteristics

- 6.5 Output Voltage Turn-on at Start Up

- 6.6 Output Ripple Voltage

- 6.7 Frequency Synchronized to External Signal

- 6.8 DIS-pin Enable and Dis-Enable

- 6.9 Load Transient Response

- 6.10 Switch-node Voltage and Current

- 6.11 Over-Current Limit and FLT-pin

- 6.12 CISPR-25 Class-5 Conducted EMI Test Result - Pass

- 6.13 Thermal Images at Full Load

- 7 Transformer Details

- 8 EVM Assembly and Layout

- 9 List of Materials

- 10Revision History

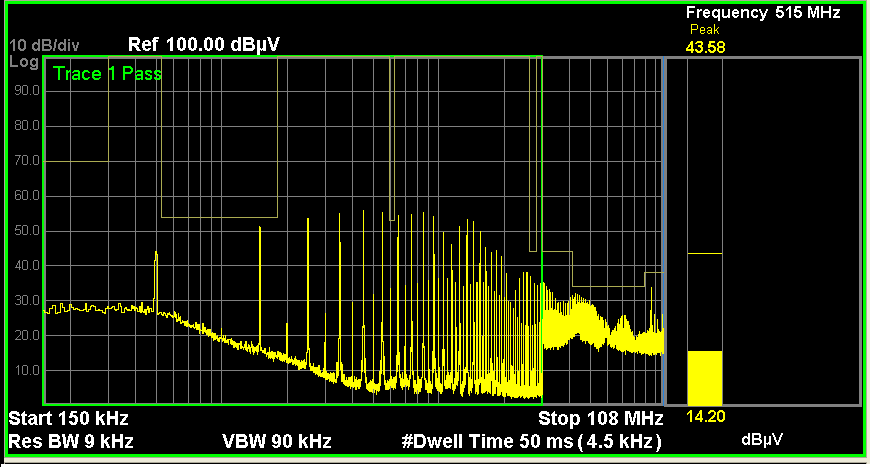

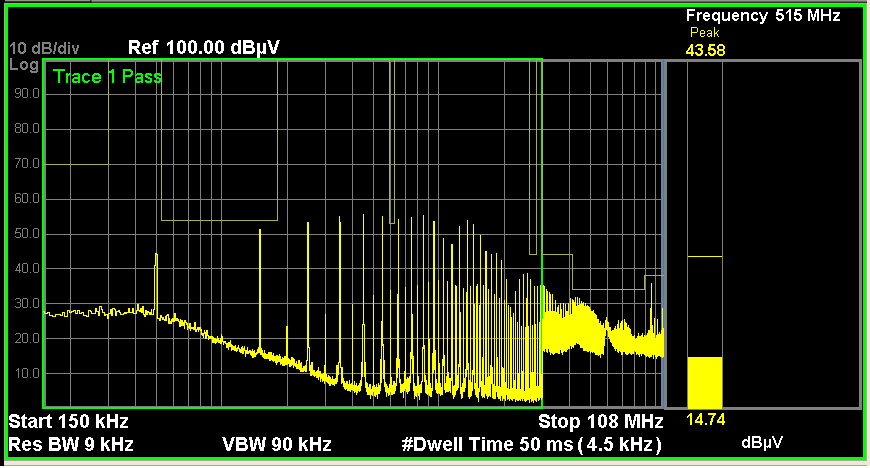

6.12 CISPR-25 Class-5 Conducted EMI Test Result - Pass

The LLC board EMI test results present a pass in terms of CISPR-25 Class-5 Conducted EMI Peak Limits. The results shown in the below figures are based on the LLC board with L1, D5, R4 and R23 removed, and connect L3 (pin 3 and 4) to J2 and J1. The connection from L3 to J2 and J1 is through a twisted pair of wires.

Figure 6-19 Peak Limits on Positive Polarity (LLC Board), Pass

Figure 6-19 Peak Limits on Positive Polarity (LLC Board), Pass Figure 6-20 Peak Limits on Negative Polarity (LLC Board), Pass

Figure 6-20 Peak Limits on Negative Polarity (LLC Board), PassNote:

Please note this was evaluated on an EMI station for pre-qualification purpose only. It is recommended that all final designs be verified by an agency-qualified EMI test house.