SSZT111 december 2021 ADS127L11 , REF6041 , THS4551

Recent trends to miniaturize industrial products have created new challenges for precision data-acquisition systems. Designers must balance solution size and power consumption of the overall system while enabling more precise signal measurements at higher bandwidths – while making trade-offs along the way.

In this article, I’ll discuss these challenges in detail, focusing on the role of the analog-to-digital converter (ADC) in industrial systems.

| Higher AC and DC performance in a 50% smaller package | |

|

Maximize channel density with the ADS127L11 precision wideband ADC. |

ADC Package Size

Much like consumer electronic products, there is an increasing push to reduce both the size and power consumption of industrial equipment as well. As long as there are no capability and performance sacrifices, users prefer smaller, lighter portable or semiportable data-acquisition equipment because it’s easier to transport around labs or out in the field. Miniaturized programmable logic controller plug-in modules take up less space inside control panels on the factory floor, and secondarily, less shelf space is needed for equipment stock and back-up inventory for spare parts.

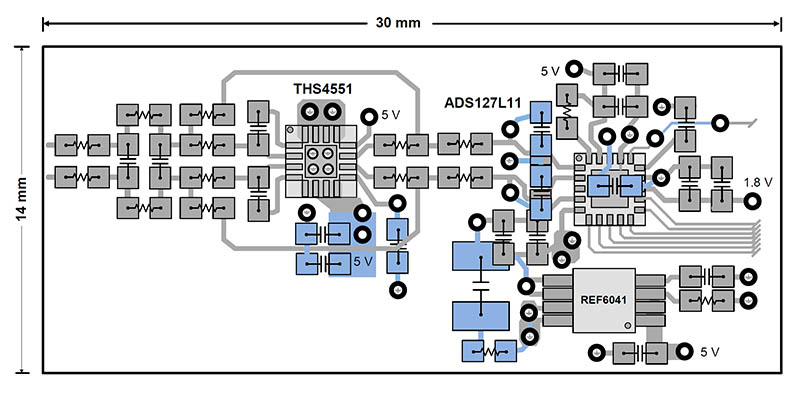

Of course, a small product design is directly related to the size of the electronics within. Figure 1 shows a layout of a data-acquisition system using TI’s THS4551 fully differential amplifier with fourth-order low-pass filter, the REF6041 voltage reference with integrated buffer and the ADS127L11 wideband ADC. Given the latest technological advances, it’s worth noting that the converter is no longer the largest component in the design.

Figure 1 Typical Analog-front-end Printed Circuit Board (PCB) Layout

Figure 1 Typical Analog-front-end Printed Circuit Board (PCB) LayoutADC Power Consumption

Minimizing power consumption is important to extend the battery run time of portable equipment, but in addition, achieving low power consumption can translate to smaller, lighter equipment – possibly at reduced cost – by reducing four parallel-connected battery cells to three, for example.

Reduced power consumption also benefits offline-powered equipment as well. Low power dissipation reduces temperature rise within the enclosure, which can extend product lifetimes by reducing the average junction temperature of the integrated circuits (ICs) – in some cases reducing or eliminating forced air cooling. Conversely, eliminating vent slots from product enclosures or control panels reduces the amount of dust and vapors condensing on the PCB surface, which if operated in harsh environments at prolonged exposures could lead to field equipment issues.

Reducing power consumption can also translate to an overall smaller size of the power-supply magnetics. This size reduction, of course, leads back to smaller enclosure options.

ADC Resolution

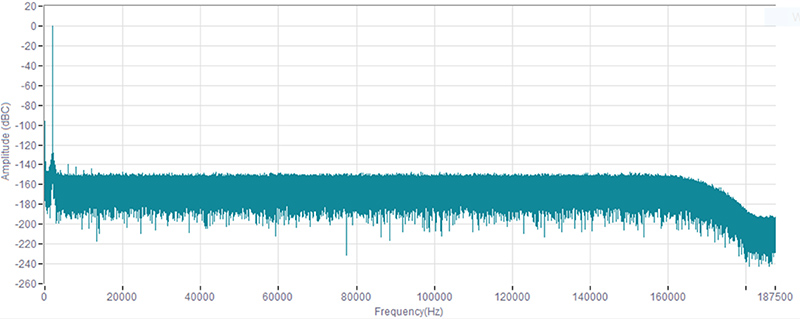

Contributing noise sources can limit measurement resolution in a data-acquisition system (from the reference voltage and input signal-conditioning circuit), but many satisfactory component choices exist to help minimize contributing noise effects. Arguably, the primary factor of system resolution for any industrial equipment measuring AC signals, such as vibration/acoustic monitoring and general-purpose data acquisition, comes down to the converter. The converter should be free of tones and other spurious frequencies that limit measurement resolution, with low broadband noise to resolve small signal levels and low distortion for good spectral performance.

Figure 2 is an example of good spectral performance for a precision data-acquisition system. The system components used for this data are again the THS4551, REF6041 and ADS127L11.

Figure 2 ADC Spectral Performance

Figure 2 ADC Spectral PerformanceADC Bandwidth

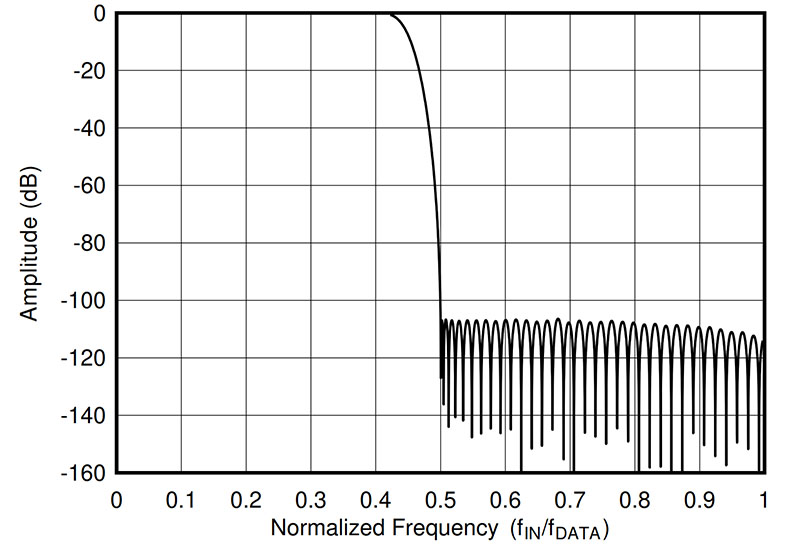

During the precision acquisition of AC signals, the converter should have frequency characteristics approaching the ideal – a flat passband with low ripple, a sharp transition band to conserve as much bandwidth as possible and a stopband in full effect at the Nyquist frequency to minimize signal aliasing. Once signal aliasing occurs, the signal cannot be corrected by post-processing, so it is important to attenuate the out-of-band signals as economically as possible.

A wideband delta-sigma ADC provides these filter properties, including the crucial function of antialiasing. A wideband – or brick-wall filter – comes from the digital filter with the above-mentioned passband, transition band and stopband performance. The filter itself is only made possible by the concept of oversampling, and for the best power and resolution metrics, is usually used in conjunction with a delta-sigma ADC. Figure 3 shows the frequency response of a typical wideband ADC.

Figure 3 Wideband ADC Filter Response

Figure 3 Wideband ADC Filter ResponseThe stop band attenuation of the wideband filter eliminates the need for an external anti-alias filter – typically needed with a successive approximation register ADC – both of which are designed to provide signal attenuation at the Nyquist frequency. An equivalent order of an external anti-alias filter would be very high and costly to implement. Avoiding an external filter saves design and component costs, as well as avoiding a lot of in-band phase shift.

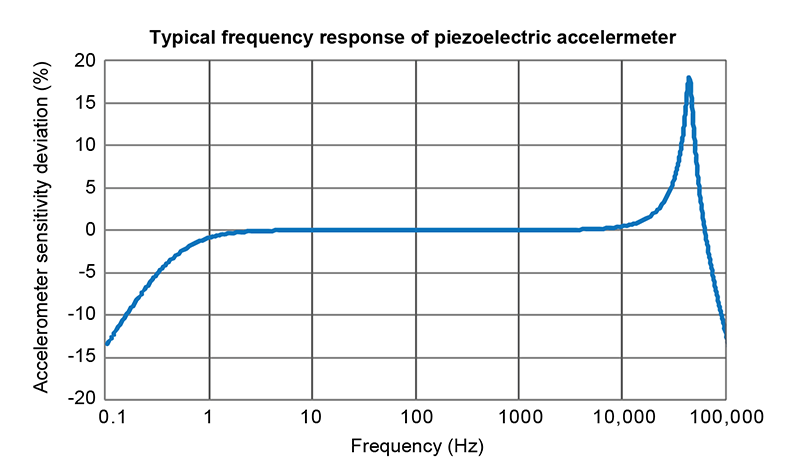

Figure 4 Typical Piezo Accelerometer with Response Peaking at Resonance

Figure 4 Typical Piezo Accelerometer with Response Peaking at ResonanceOne drawback of integrating a wideband filter into the converter is the silicon die area required by the many logic gates in the filter implementation. The IC designer of an ADC can leverage the small transistor size with associated low threshold voltage to reduce power consumption, but at the same time will require the transistors to be analog-friendly – that is, can achieve excellent analog section noise and linearity performance. TI has developed an IC process that meets both criteria.

A small transistor geometry reduces stray capacitance (C) associated with the logic gates, resulting in lower internal power loss. Equation 1 expresses the power loss (P) operating at clock frequency (f) and operating voltage (V):

Reducing the threshold voltage reduces the power loss associated with the V2 power-supply term. One further advantage is reduced coupling of digital switching noise to the analog section by reducing the peak switching currents by virtue of the small transistor size used in the ADC digital section.

Conclusion

With the ADS127L11, Texas Instruments has designed a wideband ADC with 50% smaller package, 50% less power consumption, 3-dB improved resolution and 50% wider signal bandwidth compared to existing wideband converters. The ADS127L11 brings size and power elements together without sacrificing resolution or bandwidth.

When selecting a precision wideband ADC, designers no longer have to choose between optimizing power consumption, package size, resolution and measurement bandwidth. Selecting the converter becomes easier for next-generation data-acquisition equipment, as TI addresses the demand of increasingly small form factors, lower power consumption and improved resolution.