SSZT380 november 2019 TPSM265R1

It’s not unusual to find industrial automation control equipment like field sensors (for proximity, pressure, flow or temperature, for example) housed in increasingly inconspicuous packages. Figure 1-1 shows an example of a proximity sensor housed in a tiny screw (which can be as small as 8 mm or in some instances even smaller). While the electronics that go into the housing have to be ultra-small, they still need to be rated for the right parameters to ensure long-term equipment reliability.

Figure 1-1 Typical proximity

sensor

Figure 1-1 Typical proximity

sensorAddressing the challenges of unregulated input voltages

Electronics in smart sensors may include a low-power microprocessor, analog-to-digital signal-processing circuitry and a voltage regulator. Sometimes, designers might not consider power until the end of the design process; therefore, the space allotted to power can be really sparse.

Sensors in process automation need to withstand overvoltage transients. The severity of voltage transients depends on how the 24 V was derived. In some situations, where the lead lengths cover long distances in the field, the industrial 24-V bus may experience higher voltage transients. In addition, field applications could have clamp circuits that limit the voltage transient to a safe extra-low voltage limit. This means that in a short-circuit condition; the output of the industrial bus could be stuck at 60 VDC.

Considering another example, a 24 VAC could be an input source. The maximum root-mean-square voltage of such a supply can often swing to 28 V, leading to a peak voltage delivered that’s close to 40 V. The overvoltage protection setting on the input supply could be about 120% of the peak voltage, which takes an input voltage close to 48 V.

In these examples, it is important to use a voltage regulator rated for the maximum DC voltage at the input to ensure uninterrupted operation of equipment like field sensors.

Ensuring appropriate pin spacing for long-term reliability

The TPSM265R1 is a high-voltage embedded power module rated for 65 V that integrates the voltage regulator and inductor. This gives the device enough margins to cover potential overvoltage conditions. However, just because a power module has an integrated high-voltage regulator doesn’t mean that you can safely rate it for the high voltage. To properly rate the device for a higher input voltage requires appropriate design of the pad/pin spacing on the module. The Association Connecting Electronics Industries has a standard called IPC 2221-B which goes over this in detail.

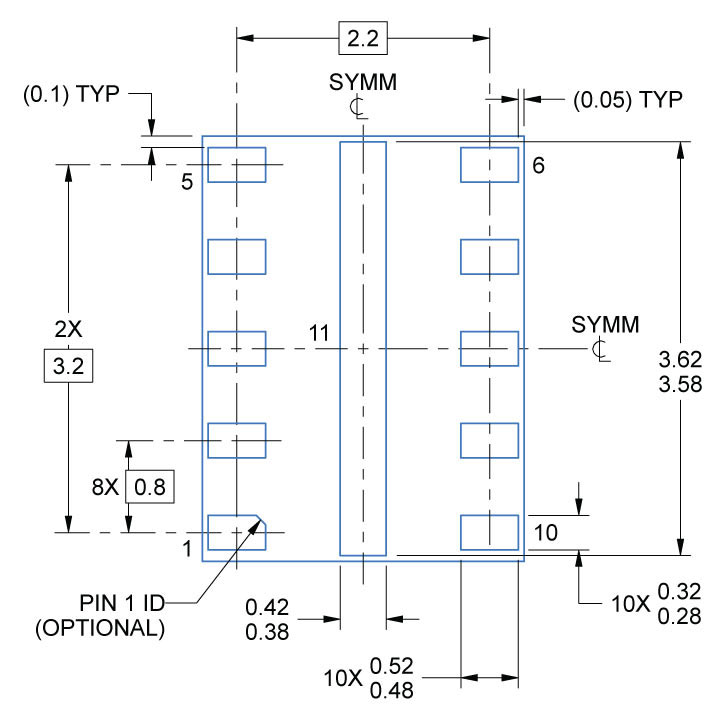

Figure 2 shows the pin pitch of the TPSM265R1, which is 0.8 mm; the width of the pad is typically 0.3 mm. From edge to edge, the space between the pads is 0.5 mm, in compliance with the IPC-2221B requirement.

Figure 1-2 TPSM265R1 package drawing

Figure 1-2 TPSM265R1 package drawingMeeting the requirement for a small solution size

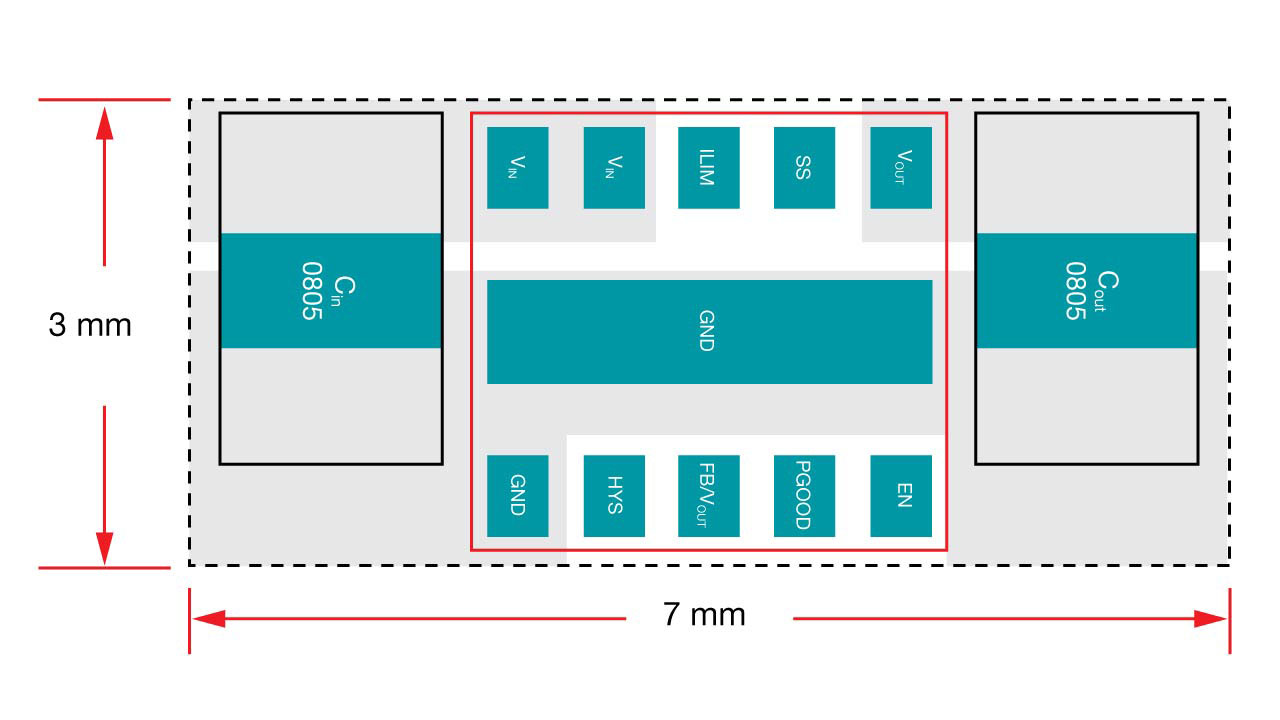

IPC spacing requirements put system designers at odds with the requirement for miniaturization. After all, I began this technical article talking about how electronics need to fit into an 8-mm screw. To address both spacing requirements and miniaturization requirements, designers have to be smart about designing the power module. TI designed the layout of the TPSM265R1 package with a small-solution space in mind. Figure 1-3 shows an example layout, with the minimum required components for a fixed-voltage option of 3.3 V or 5 V.

Figure 1-3 Example layout with the

TPSM265R1

Figure 1-3 Example layout with the

TPSM265R1The module package size is 2.8 mm by 3.7 mm. To complete the circuit, you only need two capacitors. With two 0805 capacitors, the overall solution size for a 5 V or 3.3 V output can be as small as 3 mm by 7 mm. The placement of the input capacitor so close to the module’s VIN and GND pins makes for a “quiet” switching operation, with less ringing on the switch node.

When designing the power supply for small industrial automation control equipment, it’s important to choose products with appropriate ratings for a reliable operation. Well-designed power modules will not only help engineers address size challenges and ensure long-term reliability but can also help simplify the design process.

Additional resources

- Learn more about the IPC organization and the standard for pin spacing.