SSZT440 July 2019 TPS62840 , TPS63802

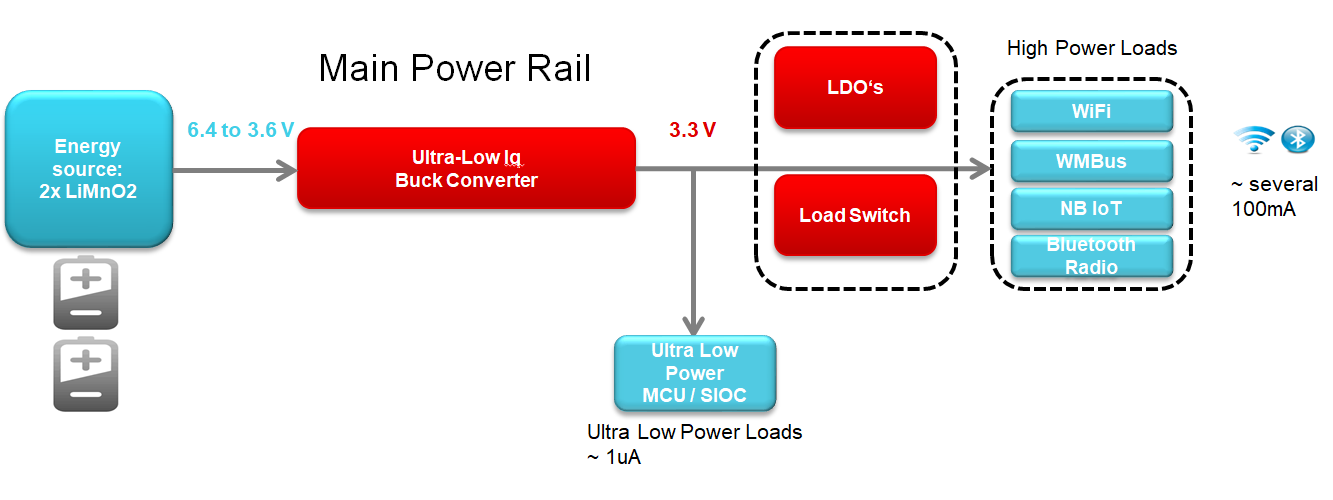

Many battery-powered applications require a step-down buck converter to work in 100% duty-cycle, where VIN is close to VOUT, in order to extend battery run time when battery voltage is at its lowest value. For example, let’s say that there are two lithium manganese dioxide (Li-MnO2) batteries powering a smart meter. Li-MnO2 batteries are primary non-rechargeable cells used increasingly in smart gas or water meters because of their long operational lives (as much as 20 years) while being more cost-effective than lithium thionyl chloride batteries. Figure 1 shows the system configuration of two Li-MnO2 cells placed in series (2s1p) and then stepped down to power a microcontroller.

Figure 1 A Smart Meter Power Architecture

Figure 1 A Smart Meter Power ArchitectureUltra-low quiescent current (IQ) DC/DC converters can help you design applications with a battery lifetime up to 20 years. The load profile of a smart meter application is not a continuous load but a variable load profile. In order to enable long battery life, the system will draw a high current only occasionally (to send a wireless signal or actuate a valve), and then go back to a very low load condition. This type of load profile enables low average current consumption in the microampere range. High efficiency at such light loads requires ultra-low IQ, especially during the off-time where current consumption could be much lower than the average current consumption. TI’s TPS62840 ultra-low power buck converter has an operating IQ of only 60 nA and can regulate a 3.3-V power rail. The TPS62840’s very low IQ in 100% mode – 150 nA – further extends battery run time.

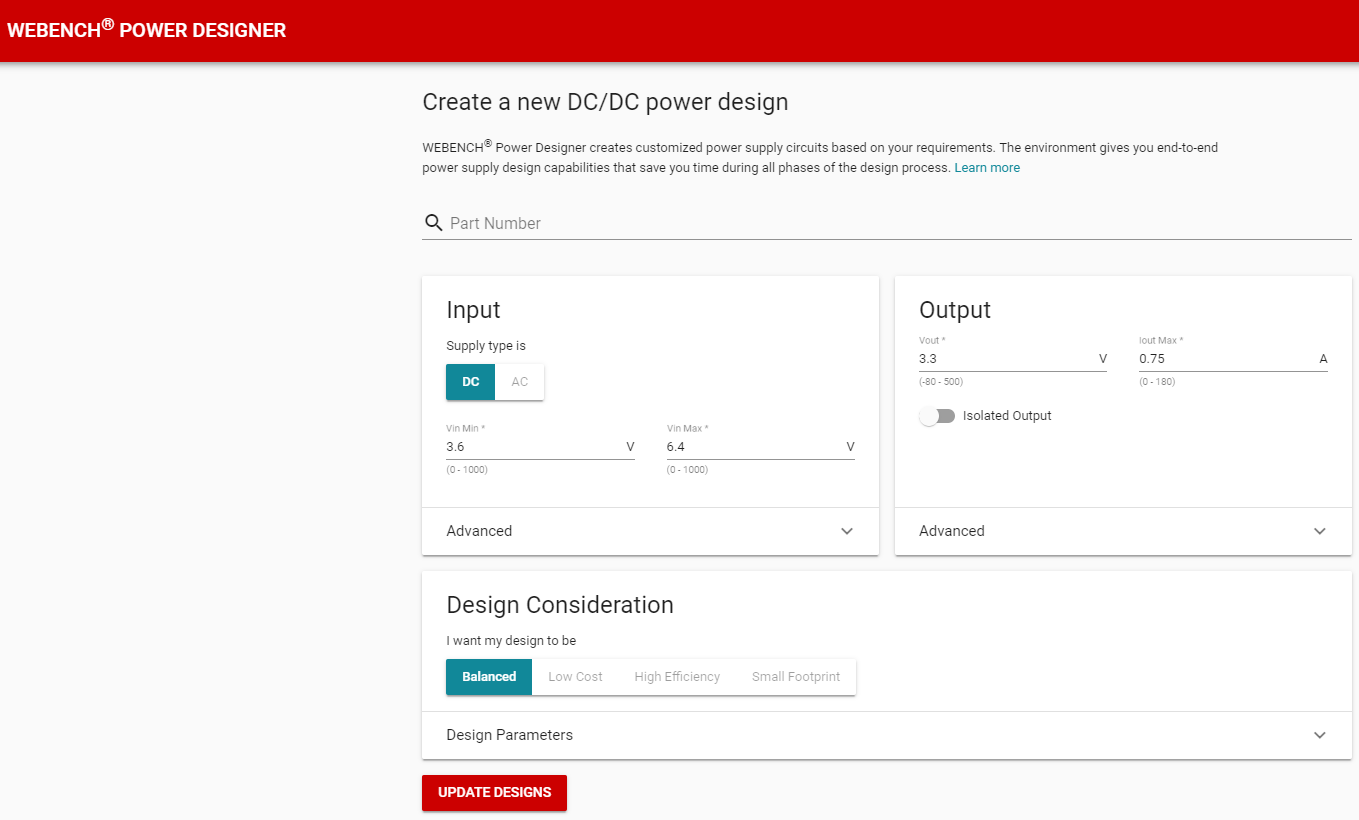

To better help you design and simulate your ultra-low power-supply circuit, WEBENCH® Power Designer is an online tool that enables the creation of customized power supply designs based on your specifications.

In our example, the average voltage per cell is around 3.0 V. The initial voltage of a cell is approximately 3.2 V when fresh, and the voltage can drop to less than 2 V when fully discharged. Assuming that each battery discharges down to 1.8 V and is 3.2 V when fresh, enter these parameters into WEBENCH Power Designer (Figure 2).

Figure 2 Design Specification Entered in WEBENCH Power Designer

Figure 2 Design Specification Entered in WEBENCH Power DesignerUsing a 3.6-V minimum input voltage in the WEBENCH Power Designer search tool yields 51 possible devices, but the TPS62840 is not one of them. Why is that?

WEBENCH focuses on two initial parameters to help you find the best device for your system:

- VINMIN > VOUT is the first check WEBENCH Power Designer looks for in the user inputs for buck converters topologies. If VINMIN > VOUT, then WEBENCH Power Designer selects buck converters as part of the solutions list. If VINMIN ≤ VOUT, WEBENCH Power Designer recommends buck-boost converters to regulate your VOUT instead of buck converters that operate in 100% Duty Cycle mode. This is because WEBENCH wants to give you a solution where your VOUT is regulated even when VINMIN ≤ VOUT.

- After passing the first check, the second check verifies if the calculated duty cycle is greater than the max duty cycle specified in the buck converter datasheet. For buck converters that can operate in 100% duty cycle mode, 99.9% is used as the threshold. Losses are included when calculating the duty cycle. This increases the calculated duty cycle in WEBENCH Power Designer far above the ideal VOUT/VIN.

After selecting numerous devices, WEBENCH Power Designer performs detailed designs for each device. Below are three different outcomes which can be observed depending on the input parameters used:

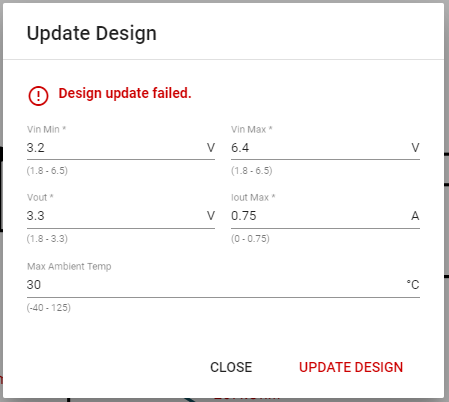

- VIN from 3.2 V to 6.4 V, IOUT_MAX = 0.75 A and VOUT = 3.3 V in the TPS62840 WEBENCH Power Designer model (Figure 3).

Figure 3 Error Message That the Input

Voltage Is Too Low

Figure 3 Error Message That the Input

Voltage Is Too LowThe design update is failing because the minimum VIN is lower than VOUT. This design does not pass WEBENCH’s first check.

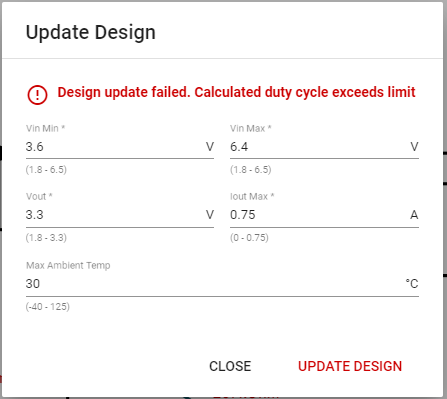

- VIN from 3.6 V to 6.4 V, IOUT_MAX = 0.75 A and VOUT = 3.3 V in the TPS62840 WEBENCH Power Designer model (Figure 4).

Figure 4 Error Message That the Duty

Cycle Is Too High

Figure 4 Error Message That the Duty

Cycle Is Too HighThe design does not update because the duty cycle when calculated includes losses such as the high-side MOSFET RDSON and inductor DCR. Here, the duty-cycle value is greater than 99.9%. This design does not pass WEBENCH’s second check.

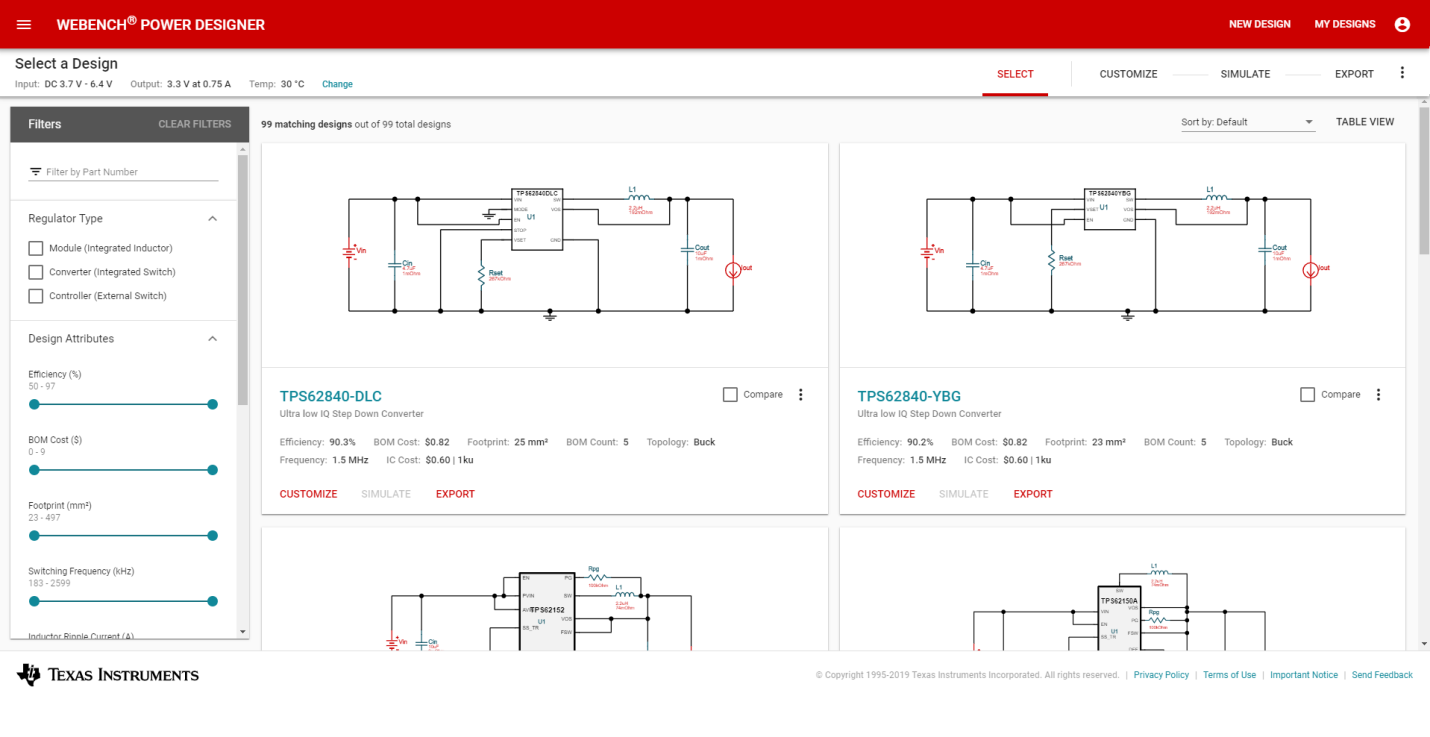

- VIN from 3.7 V to 6.4 V, IOUT_MAX = 0.75 A and VOUT = 3.3 V on the WEBENCH Power Designer Select a Design screen (Figure 5).

Figure 5 : The TPS62840 Displayed in

WEBENCH Power Designer

Figure 5 : The TPS62840 Displayed in

WEBENCH Power DesignerThe final example displays the TPS62840 since the design passed both checks.

Tips to Use WEBENCH Power Designer More Effectively When Close to 100% Duty-cycle:

- Add a sufficient delta between the input voltage and the output voltage to reduce the duty cycle.

- Reduce the output current to reduce losses and reduce the duty cycle.

Either of these solutions enable WEBENCH Power Designer to design with the TPS62840. In an actual application, operating in 100% mode is normal and generally acceptable in order to fully discharge the battery. In 100% mode, the output voltage of a step-down converter decreases as the battery voltage decreases. This can still fit the system specifications of most loads. If 100% mode or the output voltage drop is not acceptable, low IQ buck-boost devices like the TPS63802 can help maintain a regulated output voltage.

Additional Resources

- Read our technical article to find out if all rails need low Iq.

- Consider this TI Design for smart meters.