SSZT573 december 2018 ADS131A04 , AMC1301 , OPA4180

In my two previous blog posts on improving data acquisition (DAQ) for grid protection and control, I discussed the need for interfacing multiple analog-to-digital converters (ADCs) to a single processor and using the programmable real-time unit subsystem and industrial communication subsystem (PRU-ICSS) to improve sensor DAQ performance. In this post, I will discuss the DAQ accuracy requirements for voltage, current and active energy used in grid applications and discuss our High Accuracy ±0.5% Current and Isolated Voltage Measurement Reference Design Using 24-Bit Delta-Sigma ADC, which is based on the ADS131A04 24-bit delta-sigma ADC.

| Moving from conventional to intelligent substations | |

|

Learn more about intelligent substations by reading our new white paper, "Moving from conventional to intelligent substations." |

Grid Protection and Measurement

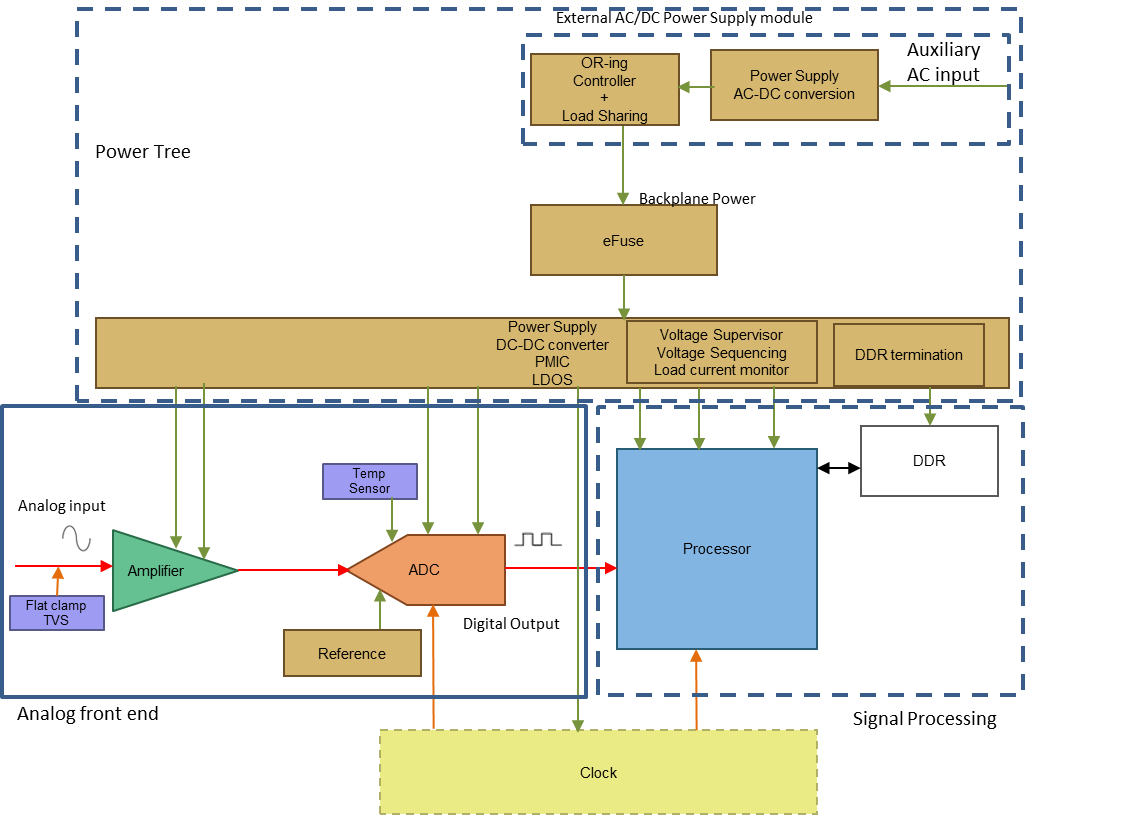

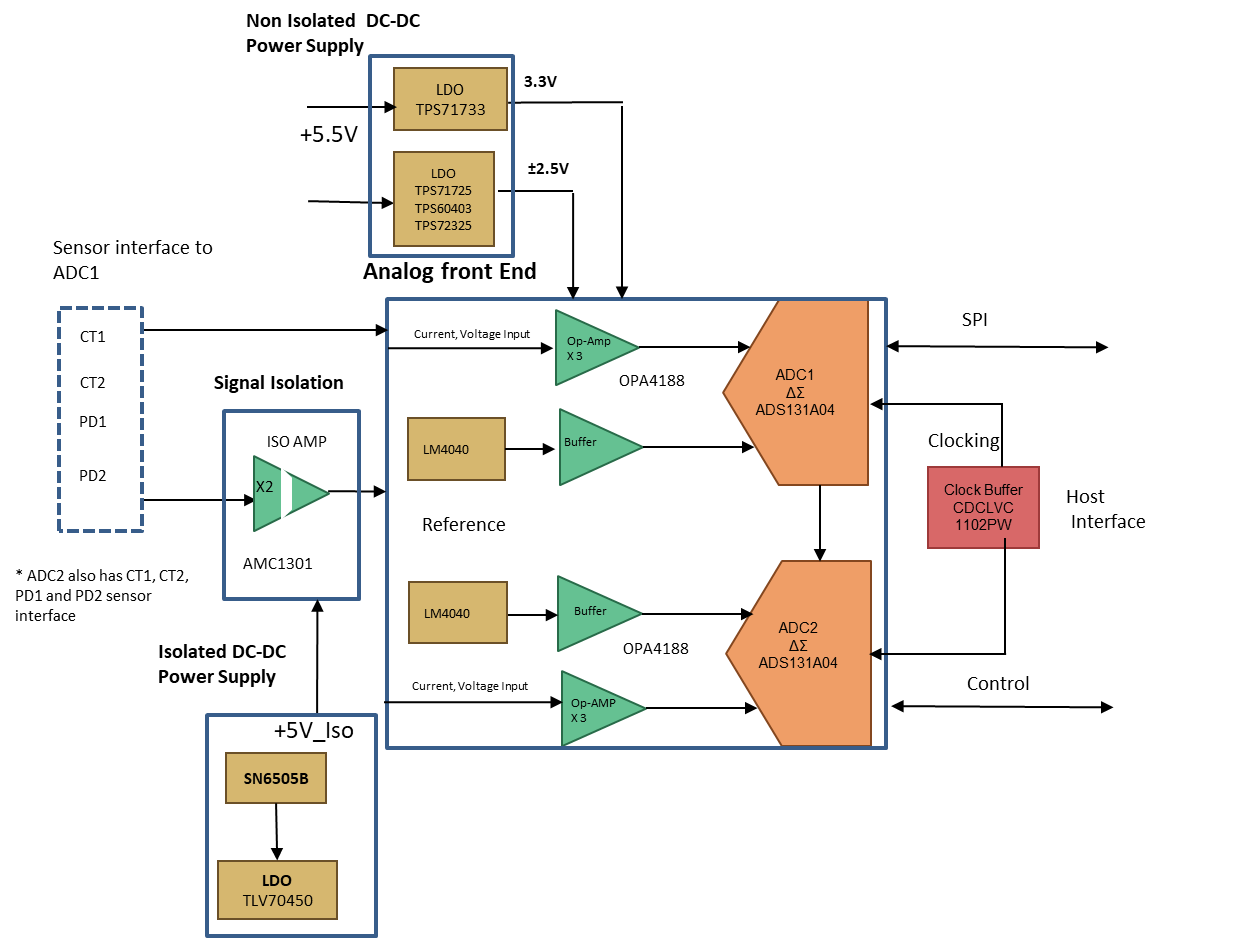

The AFE shown in Figure 1 includes a sensor interface, gain scaling to the ADC range, input transient protection, analog-to-digital conversion and a host interface.

Figure 1 DAQ Subsystems Including an AFE

Figure 1 DAQ Subsystems Including an AFEProtection and Measurement Class Accuracy Requirements for Current, Voltage and Active Energy

Current Transformers

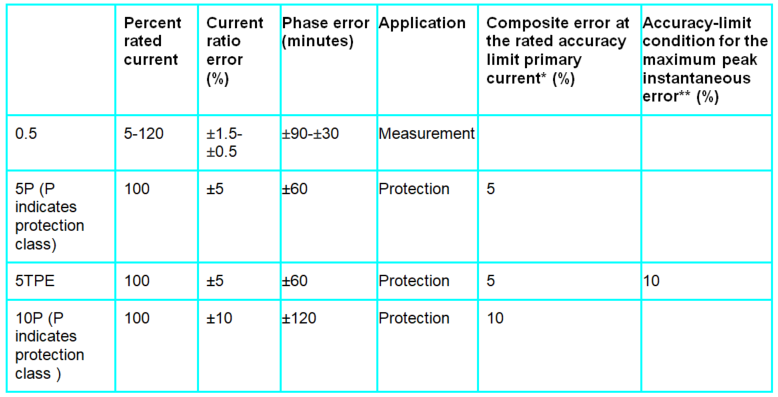

CTs are used to protect equipment against overload, short-circuit and unbalance. The accuracy of protection-class CTs is low, but still high enough to sense fault currents. In protection-class CTs, the error is specified at 100% of In. Protection class CTs are specified as 5P20, meaning that at 20 times In (accuracy limit factor) the error must be <±5%. Standard accuracy-limit factors are 5, 10, 20 and 30 and P indicates protection class. Measurement class CTs has higher accuracy requirements with a limited range.

|

*The rated accuracy limit primary current is the value of the primary current up to which the protection-class CT complies with composite error accuracy requirements.

**The peak instantaneous error assesses the error of transient DC and AC components.

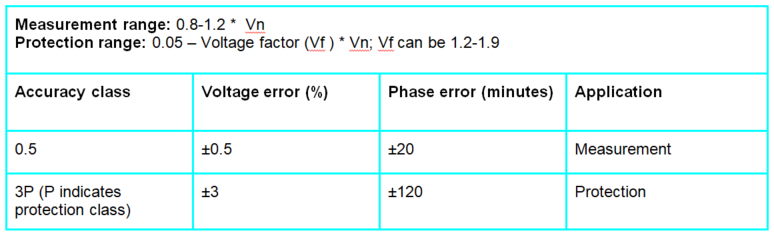

Potential Transformers

|

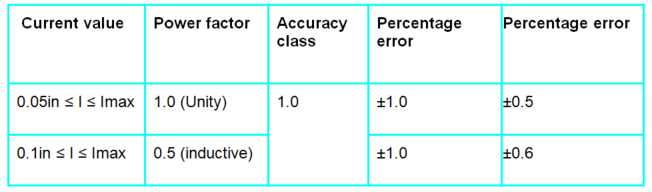

Power and Energy

|

Our reference design for current and isolated voltage measurement shows how to measure voltage, current and energy with high accuracy over a wide input range and has the functional blocks as shown in Figure 2.

Figure 2 Reference Design AFE Block Diagram

Figure 2 Reference Design AFE Block DiagramThe key functions of the AFE are:

- Isolated voltage input: An onboard resistor divider scales input voltages to 0-175 mV rms for measurement using the AMC1301 isolation amplifier with ±250-mV input and a differential output with 8.2 gain.

- Isolated power: A transformer driver and low-dropout regulator generate the required isolated supply.

- Non-isolated voltage input: An onboard resistor divider scales input voltages to 0-1,000 mV rms for measurement along with a gain amplifier.

- Current input: You can connect an external CT to an onboard burden resistor with gain amplifiers to measure the current inputs.

- Gain amplifier: A scalable fixed-gain operational amplifier scales the inputs to the ADC range.

- ADC and host interface: The output of the gain amplifiers are interfaced to the ADS131A04 24-bit delta-sigma four-channel simultaneous-sampling ADC, with an input range of ±2.5 V and a configurable reference of 2.44 V or 4 V depending on the signal input range. The ADC interfaces to the host using Serial Peripheral Interface.

- Temperature sensor: to compensate for temperature-related accuracy drift.

In the reference design, two ADCs are chained and a common clock with clock buffer is used to synchronize all channels. Chaining of two ADCs together expanded the input channel to 8 with a synchronization delay of 5-µs or less between channels.