SSZTBD8 April 2016 TPD4E02B04

USB and High-Definition Multimedia Interface (HDMI) have had an overhaul in the last three years that increased the data rate and throughput of these protocols. Data rates have grown to 6Gbps for HDMI 2.0 and 10Gbps for USB Type-C USB 3.1 Gen 2. This increase in data rates enables higher-resolution videos and faster data transfers, but it also has made it harder to protect systems using these protocols from Electrostatic discharge (ESD) strikes.

Selecting an ESD protection diode for USB Type-C and HDMI 2.0 systems requires that you consider three things:

- The I/O capacitance of the diode.

- The clamping voltage for the diode.

- The device package and footprint.

It was once difficult to find an ESD protection diode that fits all three of these considerations, but TI’s new family of low-capacitance devices can help solve the ESD protection challenge. For example, the TPD4E02B04 can provide ESD protection for USB Type-C and HDMI 2.0 systems with low capacitance, low clamping voltage and a small footprint/easy-to-route package.

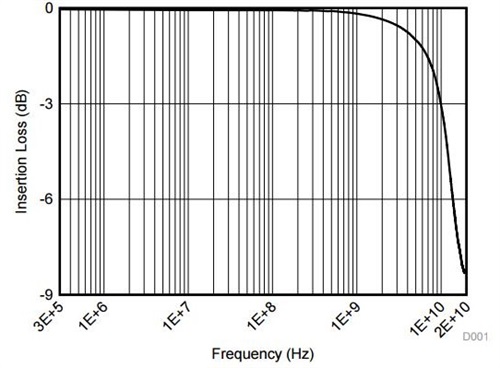

Diode Capacitance

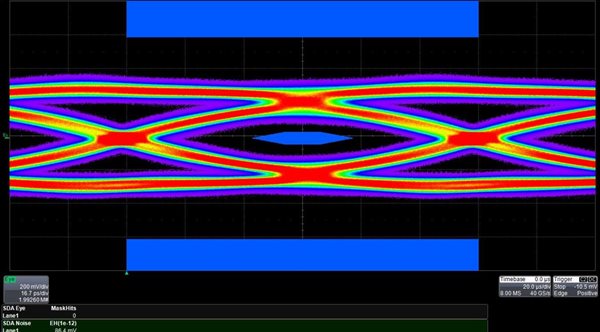

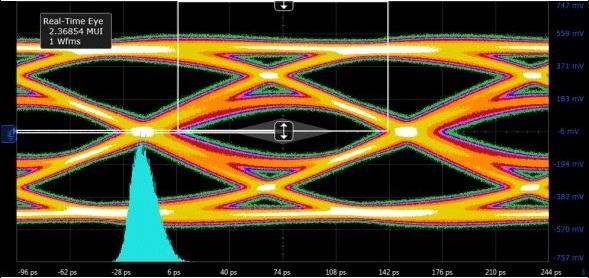

The TPD4E02B04 is a four-channel Transient Voltage Suppressor (TVS)-based ESD protection diode with extremely low capacitance. The device features a typical capacitance of 0.27pF and a maximum of 0.37pF. This low capacitance enables the use of a high-bandwidth diode, as shown in the insertion-loss diagram in Figure 1. Figure 2 and Figure 3 show that the TPD4E02B04 can pass both the HDMI 2.0 eye diagram and USB Type-C USB 3.1 Gen 2 eye diagram with little impact on signal integrity.

Figure 1 TPD4E02B04 Differential

Insertion Loss

Figure 1 TPD4E02B04 Differential

Insertion Loss Figure 2 USB 3.1 Gen 2 Eye Diagram

(with the TPD4E02B04)

Figure 2 USB 3.1 Gen 2 Eye Diagram

(with the TPD4E02B04) Figure 3 HDMI 2.0 6Gbps TP2 Eye Diagram

(with the TPD4E02B04)

Figure 3 HDMI 2.0 6Gbps TP2 Eye Diagram

(with the TPD4E02B04)Clamping Voltage

Selecting an ESD protection diode with low-enough capacitance is essential to send and receive the high-speed signals, but if the device does not have a low-enough clamping voltage, it will not protect the system from ESD strikes. The TPD4E02B04 supports low clamping voltage during ESD strikes, with a low dynamic of 0.47Ω. With this low dynamic, the TPD4E02B04 provides a clamping voltage of 8.8V at 5A Transmission-line pulse (TLP), keeping the system safe during ESD events.

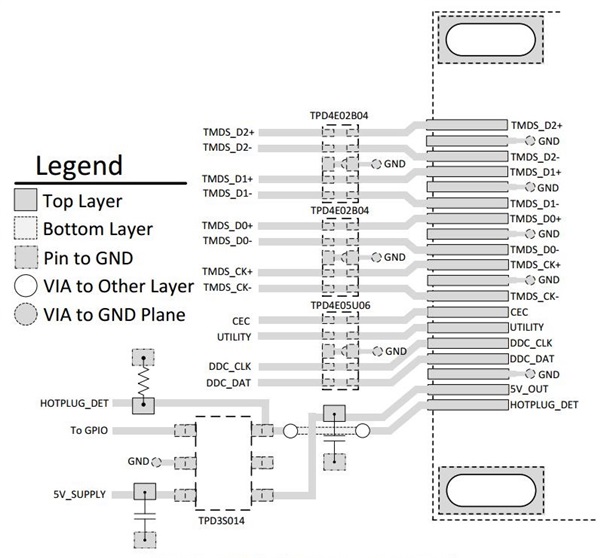

Package and Layout

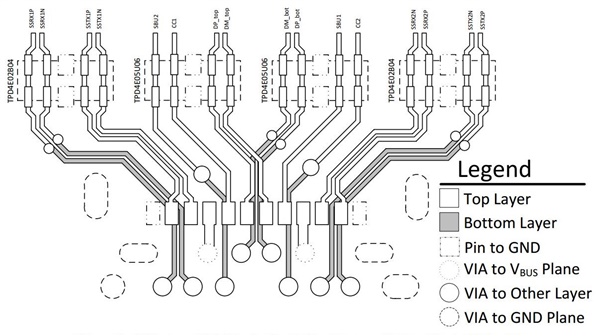

Package is an important consideration for high-speed ESD protection for ease of layout and small footprints. HDMI and USB Type-C connectors both have a 0.5mm pin pitch and high pin density. It is important to have a package that is easy to route and small enough to fit within the dimensions of the connector. The TPD4E02B04 has a 0.5mm pin pitch matching both HDMI and USB Type-C connectors. It also has flowthrough routing, enabling the signal trace to route straight through the package.

Figure 4 and Figure 5 show an example layout for HDMI and USB Type-C using the TPD4E02B04 for high speed signal protection.

Figure 4 HDMI 2.0 Type-A Transmitter

Port Layout

Figure 4 HDMI 2.0 Type-A Transmitter

Port Layout Figure 5 USB Type-C Mid-mount Hybrid

Connector with One-sided ESD Layout

Figure 5 USB Type-C Mid-mount Hybrid

Connector with One-sided ESD LayoutSo when picking ESD for high-speed data rates, always consider capacitance, clamping voltage and package. Doing so will ensure that your ESD protection solution does not interfere with the high-speed signal, robustly protects against ESD strikes, and is easy to implement.

What considerations do you face when protecting high- speed interfaces against ESD strikes? Log in to post a comment below or join the high speed interface forum.

Additional Resources

- Evaluate the TPD4E02B04 today for USB Type-C and HDMI 2.0 protection.

- Learn more about TI’s ESD protection-diodes.

- Check out these blog posts about ESD protection: