SSZTBF6 april 2016 TPS2549-Q1 , TPS62130A-Q1

With the proliferation of USB ports in new cars, providing power for each of these ports becomes more important and more cumbersome. Their sheer number and disparate locations require a robust, simple and low-cost solution to enable the fastest design time for the original equipment manufacturer (OEM) and maximum functionality for the end user.

Since a step-down converter running off the main car battery usually powers the USB ports, the converter must either tolerate or be protected from the inevitable voltage excursions or spikes on the car battery. Only a higher-rated voltage step-down converter will tolerate higher battery voltages and continue operation during the battery voltage spike.

Because most USB ports just charge portable device batteries, passengers usually tolerate a brief disruption of power delivery. Therefore, you can protect the step-down converter from brief periods of higher battery voltage with an overvoltage protection circuit instead of designing a step-down converter to withstand the overvoltage. The overvoltage protection circuit disconnects the step-down converter from the battery whenever the battery voltage is too high. If surviving an overvoltage on the input is required, you must use this type of circuit with a lower-rated voltage device such as the TPS62130A-Q1 step-down converter. This automotive device accepts up to 17V and delivers 3A of current. Through its synchronous rectification, it is efficient; its 3mm-by-3mm package is small for a converter of its power level.

Besides tolerating or being protected from higher battery voltages, many USB ports also need the capability to regulate 5V at the USB port to meet the USB specification, even among variations in load current and the corresponding variable voltage drop across the wiring in the car. This cable-drop compensation is especially important for those USB ports that locate the step-down converter in the engine control unit (ECU) and not near the actual USB ports throughout the vehicle. A clear advantage of placing the step-down converter in the ECU is that a single printed circuit board (PCB) contains all of the electronics instead of having numerous individual PCBs for each USB port – this saves cost. A disadvantage is that cable-drop compensation is then necessary for each step-down converter.

To overcome this disadvantage, the TPS2549-Q1 USB port charging-controller incorporates three useful functions: current-limiting circuitry to protect the port from overcurrent conditions, the negotiation required to communicate between the USB device and USB host, and a dedicated pin that allows simple cable-drop compensation implementation. The pin easily interfaces with any step-down converter to adjust its output voltage as the USB port’s current draw varies.

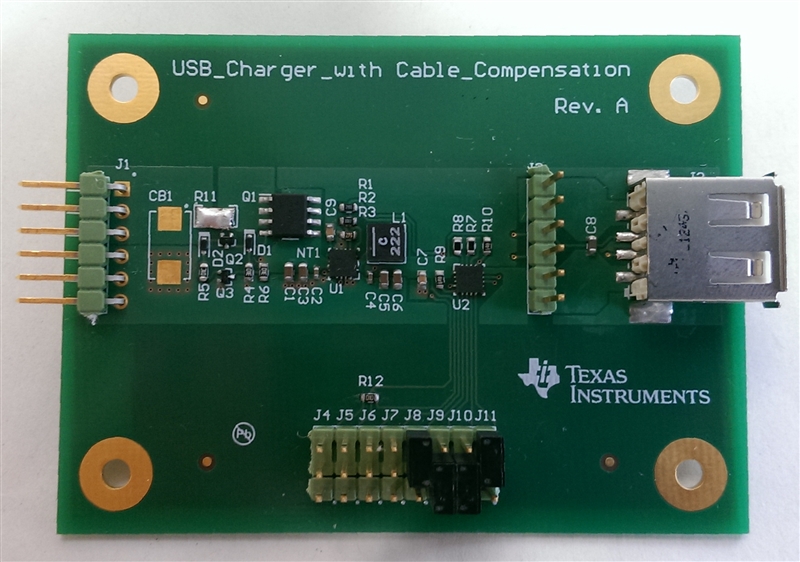

The TI Designs Automotive USB Charging Port Supply Reference Design with Charging Controller and Cable Compensation demonstrates all of the required functionality for a USB port – overvoltage protection, step-down converter and USB charging controller with cable-drop compensation support – on a single PCB. Figure 1 shows the solution, which is small and simple.

Figure 1 PMP9765 Demonstrates a Complete USB Port Power

Solution with Overvoltage Protection and Cable-drop Compensation

Figure 1 PMP9765 Demonstrates a Complete USB Port Power

Solution with Overvoltage Protection and Cable-drop CompensationA small and tested solution with everything you need to implement a full-featured USB port in a car. Input overvoltage protection keeps the electronics safe, while the USB port controller enables the full functionality of the port. What else do you need to power your automotive USB ports?

Additional Resources:

- Read the Automotive USB Charging Port Supply Reference Design with Charging Controller and Cable Compensation (PMP9765) test report.

- Read the blog: Keep your switching frequency above the AM radio band