SSZTC93 August 2015 LM5001 , LM5017 , LM5020 , LM5022 , LM5160

Power supply designers often use isolated DC/DC converters to realize galvanic isolation, meet safety requirements and enhance noise immunity. When designing an isolated DC/DC converter, output voltage regulation accuracy is one of many design objectives to consider and the required level can vary from one application to the next. Better than ±5% overall voltage regulation is adequate in some while ±10% might be necessary for others.

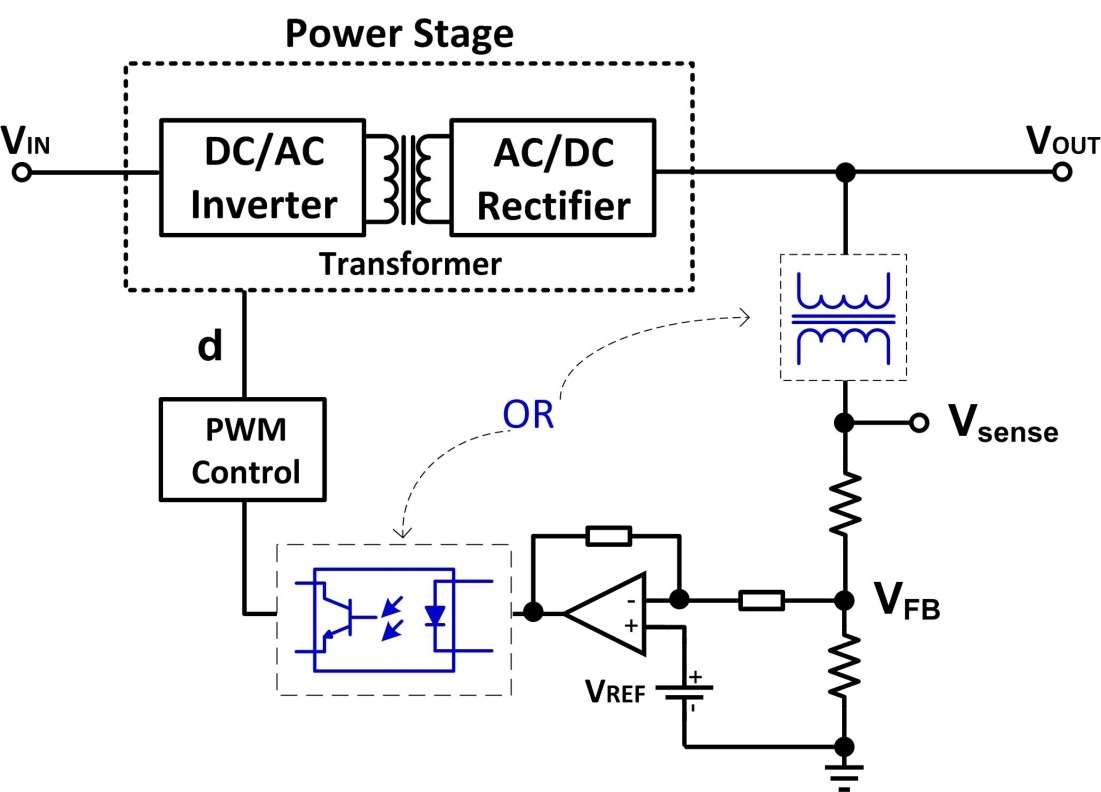

The many power management topologies and regulating schemes for isolated DC/DC converters differ widely in voltage regulation accuracy. For example, the feedback and control of a closed-loop isolated DC/DC converter is shown in Figure 1.

Figure 1 Feedback and Control of a

Closed-loop Isolated DC/DC Converter.

Figure 1 Feedback and Control of a

Closed-loop Isolated DC/DC Converter.In this example, a transformer is used to electrically isolate the output from the input of the power stage. In a closed-loop isolated DC/DC converter, the feedback circuitry senses the output voltage and generates an error by comparing the sensed voltage with a voltage reference. The error is then used to adjust the control variable, for example duty cycle, to compensate the output deviation. Galvanic isolation between control circuitry on the primary side and secondary side is also essential. Such isolation can be achieved by utilizing either a transformer or an optocoupler. Assuming the reference voltage is precise and stable over temperature changes, regulation accuracy mainly depends on output voltage sensing accuracy. In other words, how well VSENSE resembles VOUT.

In terms of output voltage regulation accuracy, isolated DC/DC solutions fall into one of three categories: regulated, unregulated and semi-regulated.

- Regulated isolated DC/DC converters such as the LM5001 or LM5022, sense and regulate output voltage directly on the secondary side. An optocoupler or digital isolator is used to transfer the control signal from the secondary to primary side. Regulated isolated DC/DC converters deliver an accurate regulation in the range of ±3% to ±5%.

- Unregulated isolated DC/DC converters are also known as open-loop isolated DC/DC converters. In the typical case of a push-pull converter with a fixed 50% duty cycle, the desired output voltage is achieved by selecting the correct transformer turns ratio. Such an open-loop converter requires neither feedback circuitry nor a signal isolator and its output voltage is not compensated for either input voltage or load current. The advantage of this solution is low cost and simplicity. A disadvantage is that VOUT will vary proportional to the VIN variation.

- A semi-regulated isolated DC/DC converter also includes a feedback circuit, however it does not sense and regulate the output directly. Instead, it senses the voltage, which resembles the output voltage on the secondary side but is commonly referenced with the primary input voltage. In this case, the semi-regulated converter can achieve as accurate an output voltage as a regulated converter, but it eliminates the need for an optocoupler. An example would be TI’s Fly-Buck™ using the LM5017 or LM5160.

To dig deeper into the design aspects of isolated DC/DC converter topologies and their voltage regulation schemes, read the article “Understanding isolated DC/DC converter voltage regulation” in EDN Magazine.

Additional Resources

- Get more information on all of TI’s DC/DC converters.

- Start a power supply design with TI’s WEBENCH Power Designer.