SLVAFR5 February 2024 DRV8214 , DRV8234

Introduction

New advancements in motor driver technologies are leading to more intelligent, efficient, and cost-effective motor control systems. TI's latest BDC motor drivers, DRV8214 and DRV8234, pave the way with technologies that transform how motor control systems are designed. This application brief explores how TI's remarkable brushed DC motor driver technologies - ripple counting, speed control, and soft start - reshape how engineers design motor control systems. You can find a comprehensive technical article on ripple counting in the Ripple Counting Application Report.

Ripple Counting

Ripple counting is a sensor less approach to motor speed and position detection. TI's patented ripple counting algorithm counts the number of ripples in the motor current waveform, filters the signal through an active band pass filter, corrects the signal through an error correction block, and outputs a digital signal used to determine the motor's position and speed.

Figure 1 Ripple Counting Versus

Encoder Size Comparison

Figure 1 Ripple Counting Versus

Encoder Size Comparison  Figure 2 Ripple Counting Versus

Encoder Size Comparison

Figure 2 Ripple Counting Versus

Encoder Size Comparison The Problem With Encoders

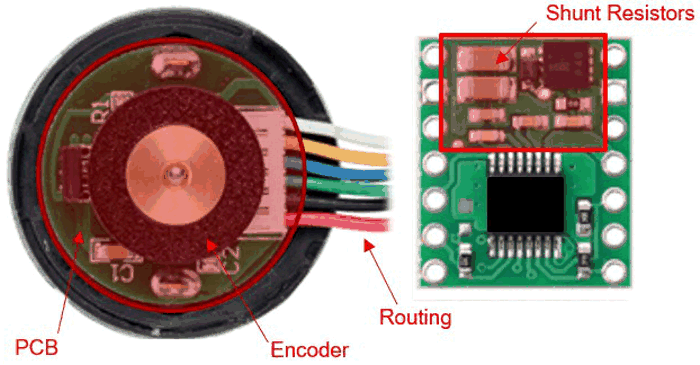

Many motor control systems rely on hall sensors, optical sensors, and encoders to determine speed and position of brushed DC motors. These external sensors are used across a wide variety of industries and markets including medical, building automation, printers, personal electronics, and robotics. Encoders and optical sensors are typically coupled with motor drivers to create closed-loop feedback control systems. While speed and position control can be critical for the safety and reliability of these systems, the external components are often expensive, complex, and can take up significant board space.

Cost

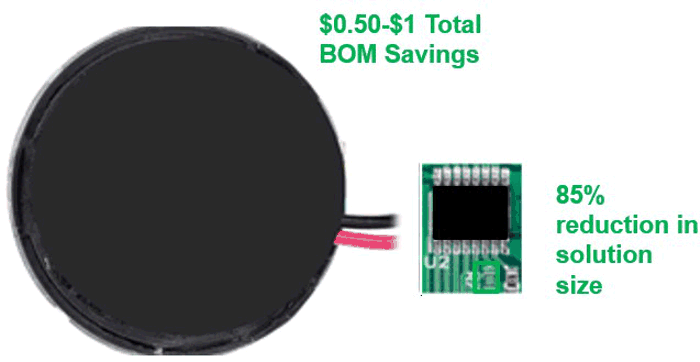

The cost of encoders can present a significant challenge to engineers and manufacturers. From initial design decisions to manufacturing choices, the cost associated with external components can impact the end products' overall competitiveness and market feasibility. In today's competitive industrial landscape, both consumers and industries alike are demanding more efficient and cost-effective designs. Additionally, high cost often forces engineers to make design compromises. Ripple counting conquers this challenge by eliminating the need for encoders and hall sensors, saving costs up to $1 per system BOM.

Size

Beyond the financial burden, the use of external sensors presents another challenge - the demand for PCB board space. Given the miniaturization trend in electronics, conserving board space is crucial, particularly in size-constrained applications such as smart locks, printers, and vacuum robots. External sensors occupy valuable real estate, which can make designing compact systems challenging. By eliminating these external sensors, we can see from Table 1 that ripple counting can reduce the total design size by 85%. Engineers no longer need a PCB attached to the back of the motor. This reduction paves the way for a more streamlined design, facilitating integration into various applications where space is at a premium.

Design Complexity

Encoders present yet another challenge - design complexity. Designing encoders requires technical knowledge of how encoders need to be configured and wired. Encoders must be calibrated and aligned to the specific motor types adding time and cost to the overall production. Often a circular PCB and embedded magnet is mounted to the rear of the motor. This leads to higher development costs and longer development time. Relying on these sensors also makes products vulnerable to supply chain disruptions and price fluctuations. An unexpected increase in sensor cost or a shortage of supply can have severe impacts on the product’s life-cycle.

TI Design

In light of these challenges, the DRV8214 and DRV8234 are game changers. By eliminating the need for encoders and hall sensors, this remarkable motor driver not only addresses the pain point of high sensor cost but offers a holistic design that improves all stages of product development. With reduced cost and simplified designs, DRV8214 and DRV8234 empower engineers to break free from constraints imposed by external sensors. These devices allow engineers to explore new possibilities in motor control, invest in innovation, and create products that are more competitive and aligned with market demands.

Speed Regulation

DRV8214 and DRV8234 also include speed regulation. Speed Regulation maintains consistent motor performance irrespective of the driver's input voltage. With speed regulation, users can program specific motor speeds in the driver's internal registers to maintain the speed as the input voltage varies over time – a common scenario, especially in battery-powered devices. The user sets a desired speed only once, leaving the DRV8234 to handle the rest. Speed regulation helps free up resources for the microcontroller so that engineers can redirect these resources to other critical tasks, enhancing the overall system's performance and responsiveness.

Soft Start

These devices also improve the longevity of the motor through soft start. The soft start feature automatically limits the inrush current during motor start-up, reducing damage to the coil windings and additional motor components. By reducing inrush current, soft start increases the reliability and lifespan of the motor driver components. This means fewer maintenance and replacement costs, making the DRV8234 and DRV8214 attractive choices for projects where durability and longevity are paramount.

Conclusion

In conclusion, the DRV8214 and DRV8234 embody a technological leap in brushed DC motor drivers. The integrated ripple-counting technology eliminates the need for expensive external encoders and hall sensors, delivering substantial cost savings of up to $1 per unit. Moreover, the technology reduces PCB board space requirements by 85%, enabling more compact and elegant designs. The speed regulation feature simplifies motor control, freeing up valuable microcontroller resources while maintaining constant speed performance, even under variable voltages. Meanwhile, the soft start feature enhances motor longevity, reducing maintenance costs and increasing product reliability.