SLYA076 july 2023 TMAG5273

3.3 3D Printing Part Orientations and Settings

The TMAG5273 was designed with 3D printing in mind for rapid prototyping, so the parts all can easily be printed on a common hobby-grade 3D printer using PLA plastic. All of the demo parts were printed with PLA filament on a Prusa MK3S with a 0.4 mm nozzle.

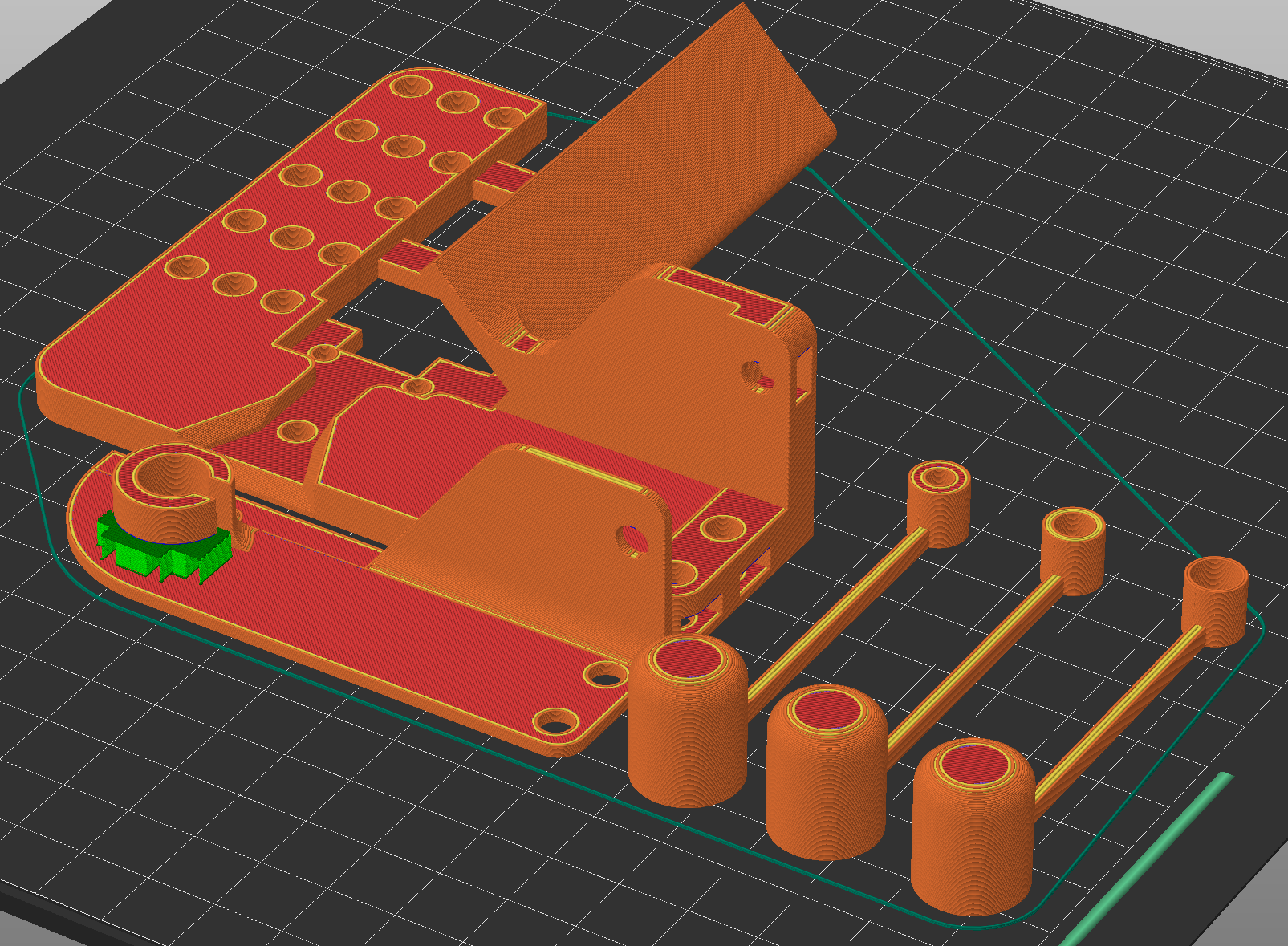

Figure 3-12 Part Orientation in

Slicer

Figure 3-12 Part Orientation in

SlicerOrient the 3D printed parts in your slicer as shown in Figure 3-12. Supports are recommended for the Liquid Level Inside Piece.stl under the float arm ring section as shown in green in Figure 3-12. The floats are printed as hollow as possible to achieve maximum float. The floats for the demo were printed with 3 perimeters and 10% infill. The hollow end part of the float can also be replaced with a foam piece or another buoyant material.