SLYY148B january 2019 – april 2023

Connected battery-powered gas and water meters

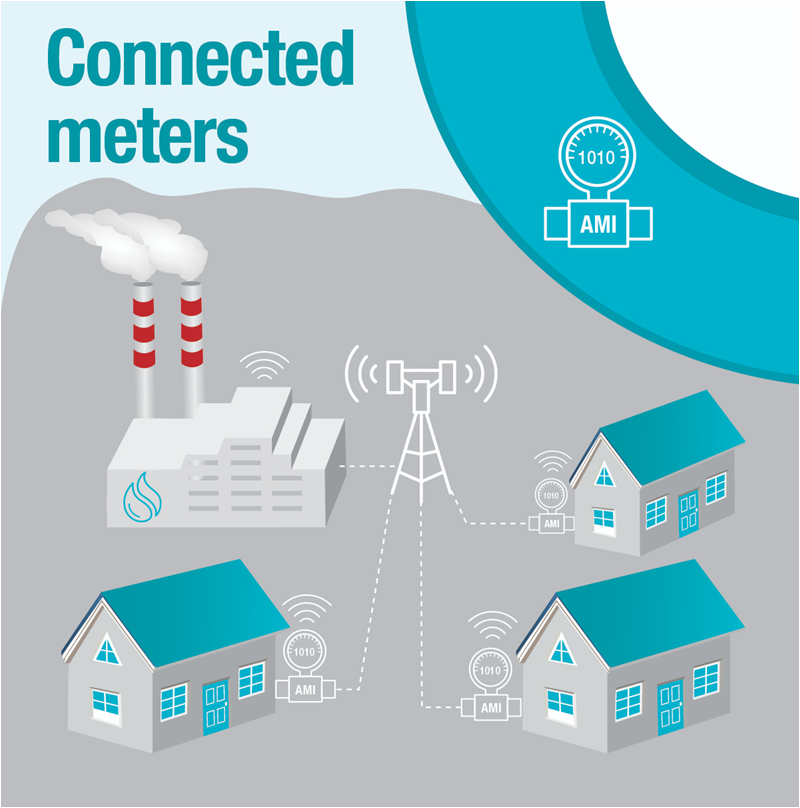

Although connected meter deployments initially started with electricity, the adoption of automatic meter reading (AMR) and smart meters within the flow meter market (gas, water, heat) is also gaining momentum.

To reduce mechanical failures, improve accuracy and add intelligence, gas and water meters benefit from:

- Ultrasonic flow measurement with high accuracy and low energy consumption.

- Wired isolated and non-isolated communication for real-time monitoring and communication of data and faults.

- Wireless communications, with long ranges to ensure connectivity or the ability to connect to an existing network infrastructure.

- Intelligent power management to maximize efficiency and provide at least 10 years of battery life.

Powering electric meters is obvious; because measurements are taken from a power line, there is power where the electric meter sits. But battery-powered technology is the norm in gas and water metrology, which makes it a lot more challenging because the power budget is much lower. There is also a commercial challenge: In many regions, entities smaller than electric providers handle gas and water. In the same area, you might have one organization owning the electric meter network, but multiple companies supplying water to residents.

Furthermore, water or gas utility providers that wish to add AMR capability face the choice of replacing all of their existing meters or installing an electronic add-on module to accurately measure the flow rate and wirelessly transmit the results. Such add-on modules offer an inexpensive solution to provide AMR features to consumers, as shown in the Low-Power Water Flow Measurement with Inductive Sensing Reference Design, which is enabled by the CC1350 SimpleLink wireless MCU.

In a gas or water meter network, the smart meter is the sensor responsible for collecting usage data and reporting it to upstream control nodes. Accurate ultrasonic measurement helps reduce mechanical failures and leads to greater system reliability. Ultrasonic measurement eliminates mechanical wear and tear by using a solid-state sensor architecture with no mechanical components. The introduction of ultrasonic flow-measurement systems-on-a-chip (SoCs) has greatly reduced the cost of transitioning to this technology.

TI’s industry-leading integrated circuits and reference designs for smart gas, water and electricity meters help original equipment manufacturers (OEMs) meet design challenges to improve measurement accuracy and extend battery lifetimes through a large selection of ultra-low-power wired and wireless interface devices.

The Ultrasonic Sensing Water Meter Front-End Reference Design helps engineers develop an ultrasonic water-metering subsystem using an integrated, ultrasonic sensing analog front end (AFE), which provides high-performance metrology with low power consumption and maximum integration. The design is based on the MSP430FR6047 ultrasonic sensing SoC. This SoC offers an integrated ultrasonic sensing subsystem AFE, which provides high accuracy for a wide range of flow rates through a waveform capture-based approach. Additionally, the device helps achieve ultra-low-power metering combined with lower system costs through maximum integration, requiring very few external components.

Similarly, the Battery and System Health Monitoring of Battery-Powered Smart Flow Meters Reference Design enables highly accurate power measurement and state-of-health projections, which forecast battery lifetimes. The monitoring subsystem also protects against overcurrent conditions, which can dramatically reduce battery life.