SNOU187 September 2021

5.2 Power Up

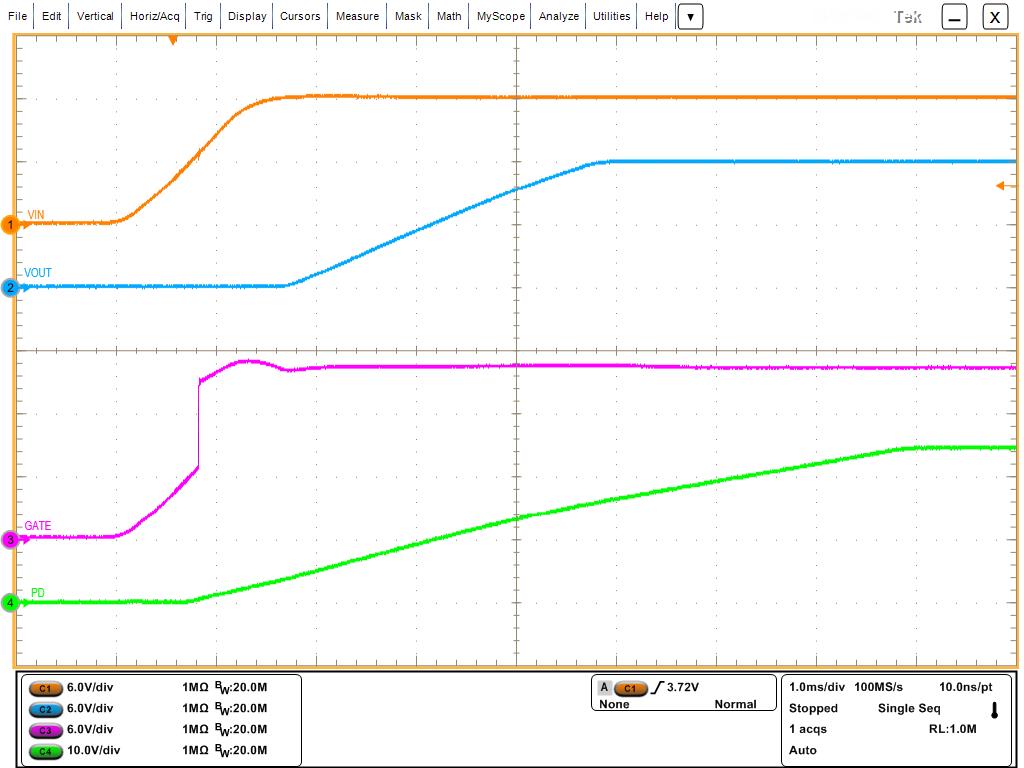

To verify the startup behavior, connect the oscilloscope to the evaluation module:

- Channel 1 - Input Voltage (Test Point Label VIN)

- Channel 2 - Output Voltage (Test Point Label VOUT)

- Channel 3 - GATE Voltage (Test Point Label GATE)

- Channel 4 - PD Voltage (Test Point Label PD)

Figure 5-2 Power Up: GATE and PD

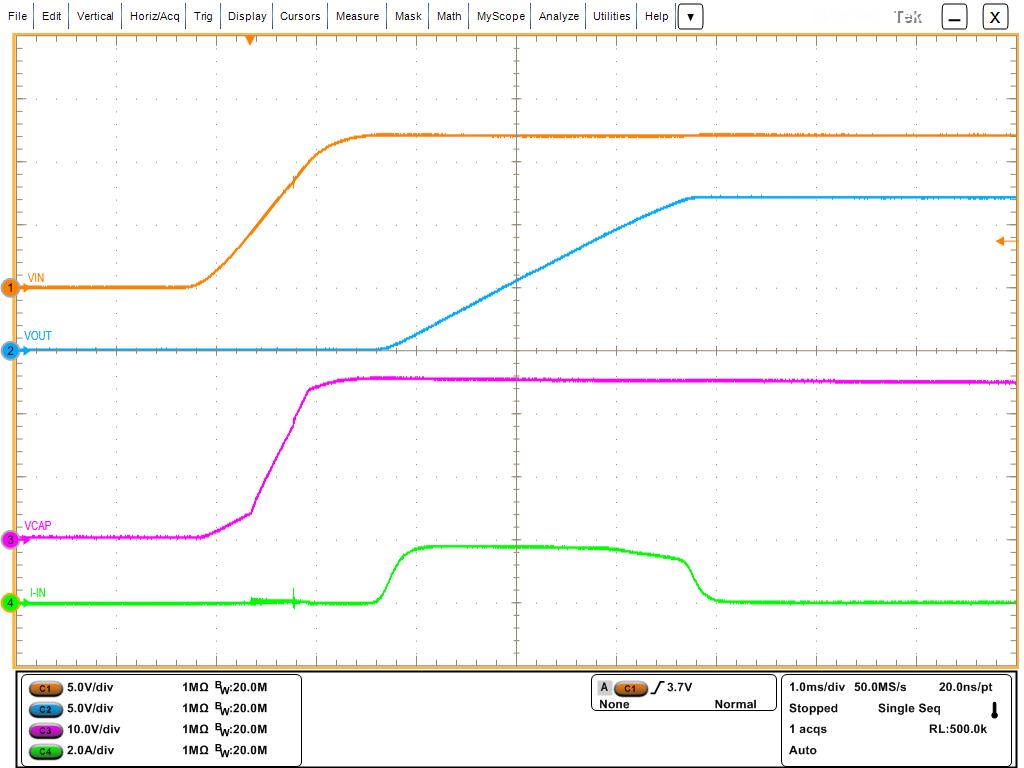

Figure 5-2 Power Up: GATE and PD Figure 5-3 Power Up: Charge Pump and Inrush Current

Figure 5-3 Power Up: Charge Pump and Inrush CurrentAdditional startup information is captured in Figure 5-3. Channel 3 captures the internal boost converter output voltage VCAP pin during startup.