SSZT064 october 2022 TPS25985 , TPS25990

As demand for data increases, so does demand for servers and data centers, and thus higher demand for power. Industry trends suggest that power per rack, which was 4 kW in 2020, will be as high as 20 kW in 2025.

Given limited physical real estate available for data centers and servers, the delivery of more power in less area is known as a high power density requirement in server power architectures. Increasing the efficiency of server power supplies can also keep cooling costs down.

Everything around us is getting data-hungry and data-driven. All of this data is stored and processed by servers in data centers, as shown in Figure 1.

Figure 1 A data-connected ecosystem

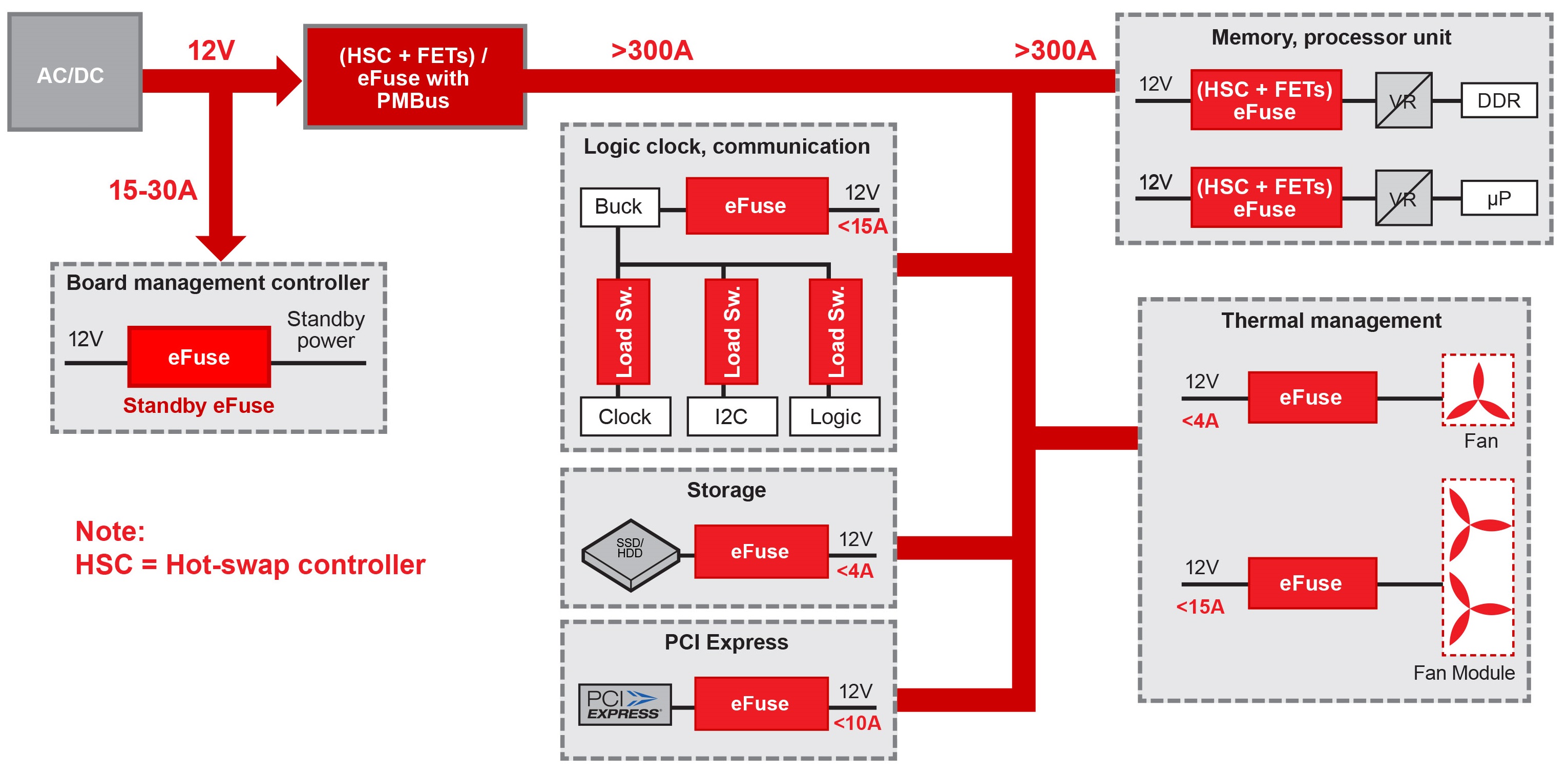

Figure 1 A data-connected ecosystemServers are usually scalable and are hot-swappable in order to meet different processing requirements and maintain high system availability. To achieve seamless hot-swap functionality, server motherboards and power distribution boards employ hot-swap controllers or eFuses. Components such as eFuses in server power supplies need to provide higher current to meet increased server power requirements. Protection devices such as hot swaps and eFuses also need to handle high peak current to match the higher peak-processing capabilities of modern microprocessors in servers. Figure 2 shows a typical server power architecture.

Figure 2 A Typical Server Power Architecture

Figure 2 A Typical Server Power ArchitectureTraditionally, high-power server designs include hot-swap controllers with multiple metal-oxide semiconductor field-effect transistors (MOSFETs). But server power and power-density requirements are increasing exponentially. To satisfy these needs and simplify these designs, consider the TPS25985 (80 A peak) and TPS25990 (60 A peak with the PMBus interface) eFuses in server power architectures. The TPS25985 and TPS25990 can support 60 ADC and 50 ADC, respectively, and have an adjustable current limit of up to 60 A and 50 A, also respectively. It is possible to stack multiple unlimited TPS25985 and TPS25990 eFuses to achieve higher current.

Achieving High Power Density

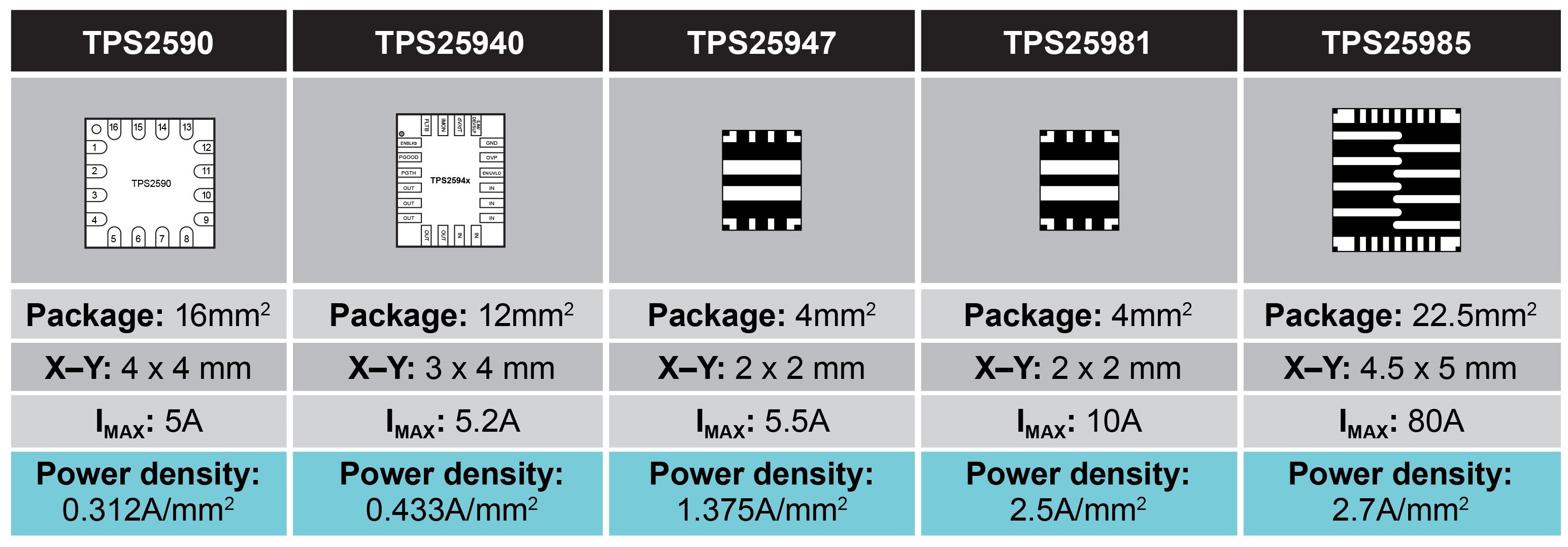

Power density is a must-have requirement for modern server power supply units (PSUs). The latest generation of server PSUs are in the range of a 3-kW (250 A at 12 V) power rating. When selecting an eFuse, it is important to have the highest current in the smallest size. The TPS25985 packs 80 A of peak current in a 4.5-mm-by-5-mm package. Figure 3 shows some of the TI’s eFuses.

Figure 3 Power-density Progression of TI eFuses

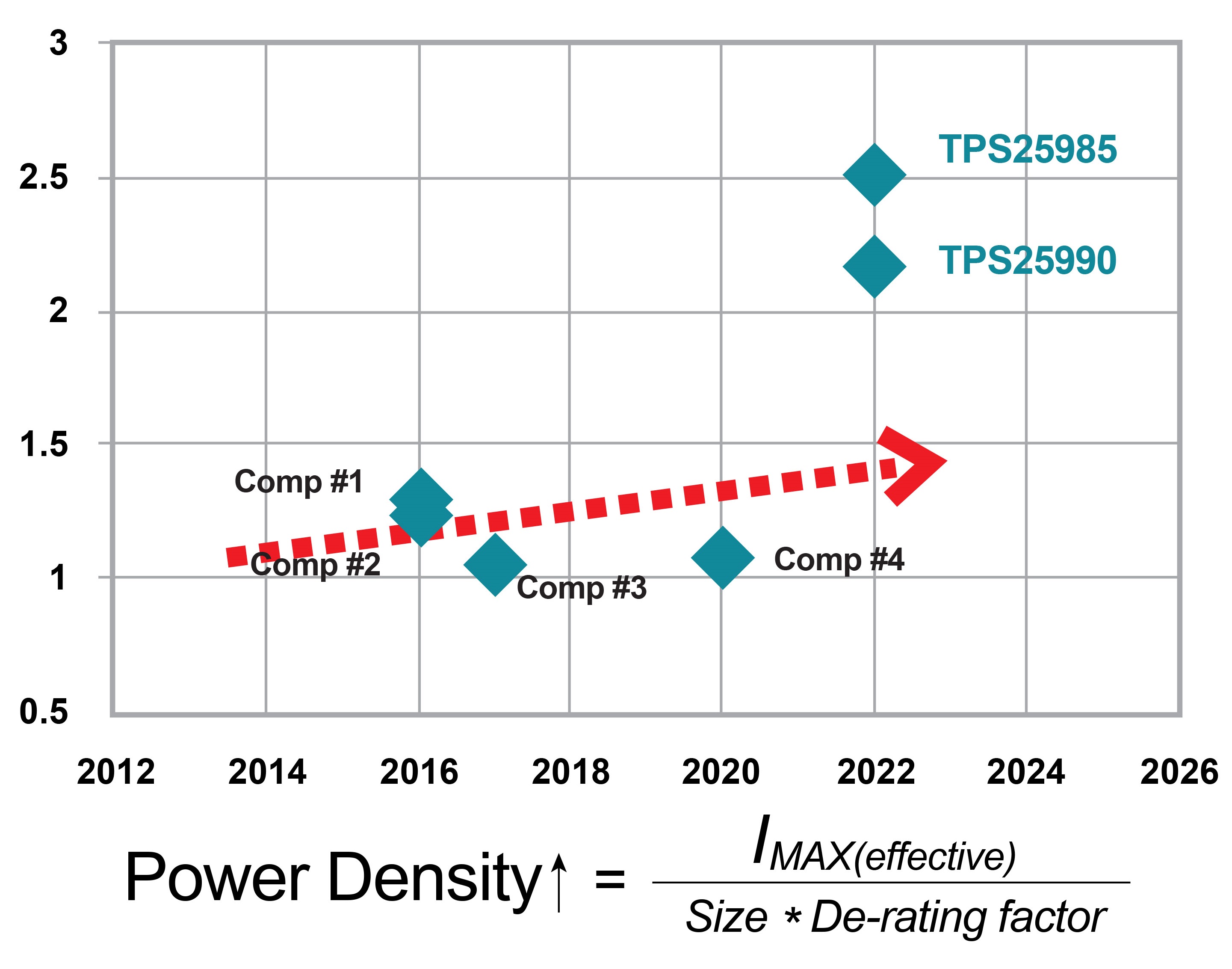

Figure 3 Power-density Progression of TI eFusesBy integrating a MOSFET, a current monitor, a comparator, active current sharing and a temperature monitor, the TPS25985 and TPS25990 eFuses significantly reduce the total printed circuit board or printed wiring board area. When connecting multiple TPS25985 and TPS25990 eFuses, the board savings and power density improve multifold. Figure 4 shows the current density of the TPS25985 and TPS25990 compared to other eFuses on the market.

Figure 4 Current and Power-density Comparison

Figure 4 Current and Power-density ComparisonCurrent-share and Current-monitor Accuracy

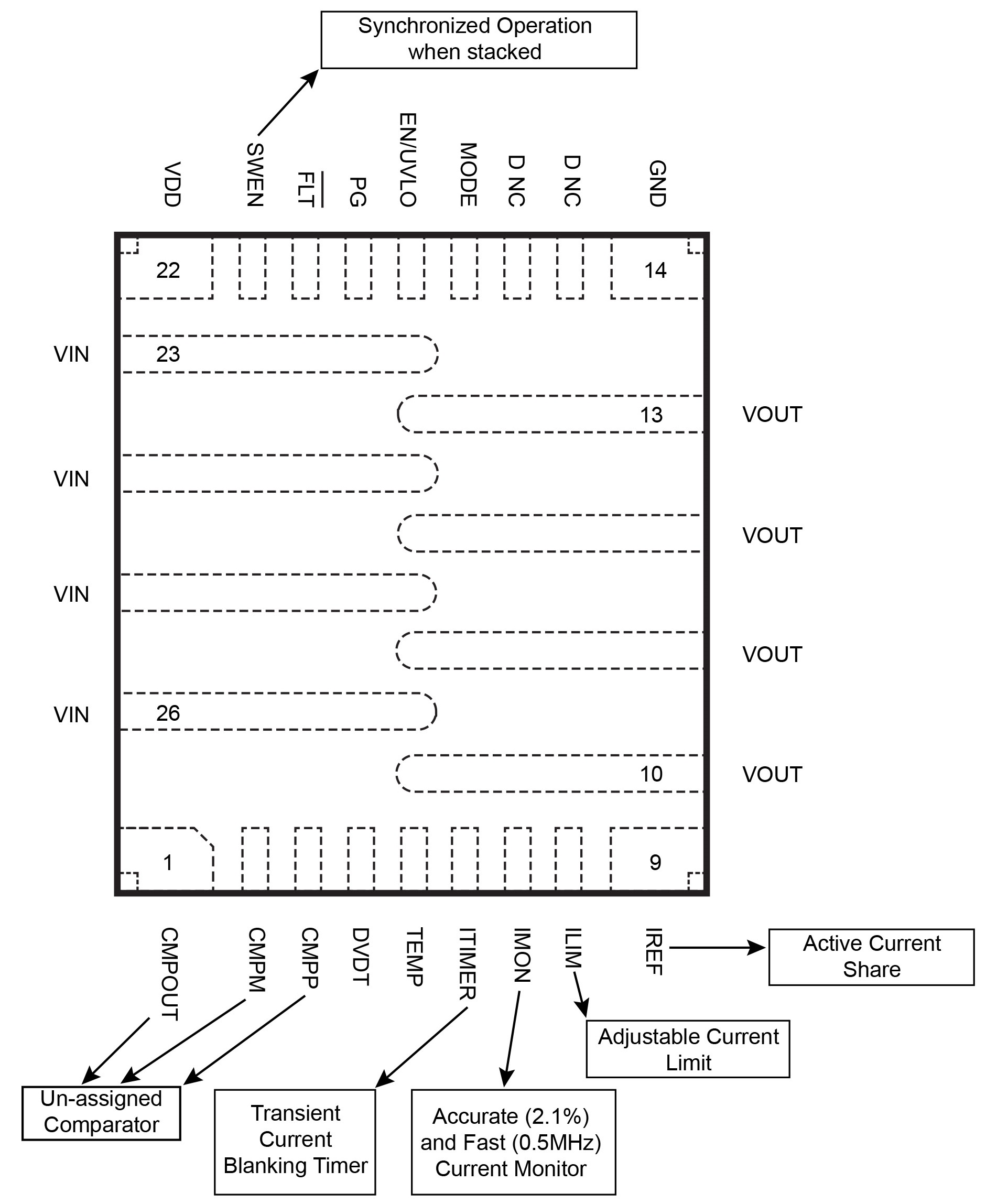

Hot-swap controllers cannot control the gates of multiple paralleled MOSFETs very precisely; therefore, current sharing by paralleled MOSFETs is not accurate. Precision amplifiers can help achieve high current-share accuracy and current-monitor accuracy, but adding them increases the total solution size. It is challenging to gauge the die temperature of the MOSFET, and therefore impossible to guarantee its thermal protection in transient and steady-state conditions. Figure 5 highlights key pins and functions of the TPS25985.

Figure 5 TPS25985 Pinout, Highlighting Key Differentiating Features

Figure 5 TPS25985 Pinout, Highlighting Key Differentiating FeaturesThe TPS25985 and TPS25990 eFuses have integrated active current sharing and direct access to MOSFET die parameters (voltage, current, temperature), which allows accurate control of all eFuse gates connected in parallel and accurate die temperature monitoring of integrated FETs. Compared to an eFuse without active current sharing, the TPS25985 and TPS25990 enable design engineers to optimize the number of eFuses and the performance of the system.

An integrated current monitor enhances server platform power management using PSYS/PROCHOT to maximize the platform’s computational throughput and power-supply utilization. These features also help optimize the front-end AC-to-DC power supply, and thus system cost. In addition, an adjustable transient current blanking timer improves system reliability and total availability by avoiding nuisance tripping.

Remote Monitoring and Control

The TPS25990 adds PMBus interface capability to the system. The TPS25990 enables single-command power cycling with an adjustable turnon delay, which allows system design engineers to sequence and reset the system remotely. The TPS25990 also offers black-box capability, where seven events are recorded with relative timestamps. The TPS25990 incorporates high-speed analog-to-digital converters that enable users to plot one signal of their choice, mimicking a digital oscilloscope. The GUI for the TPS25990, along with its other features, helps design engineers not only reduce their total development time but also quickly identify and resolve field issues, which are generally very difficult to reproduce and troubleshoot.

Thermal Considerations

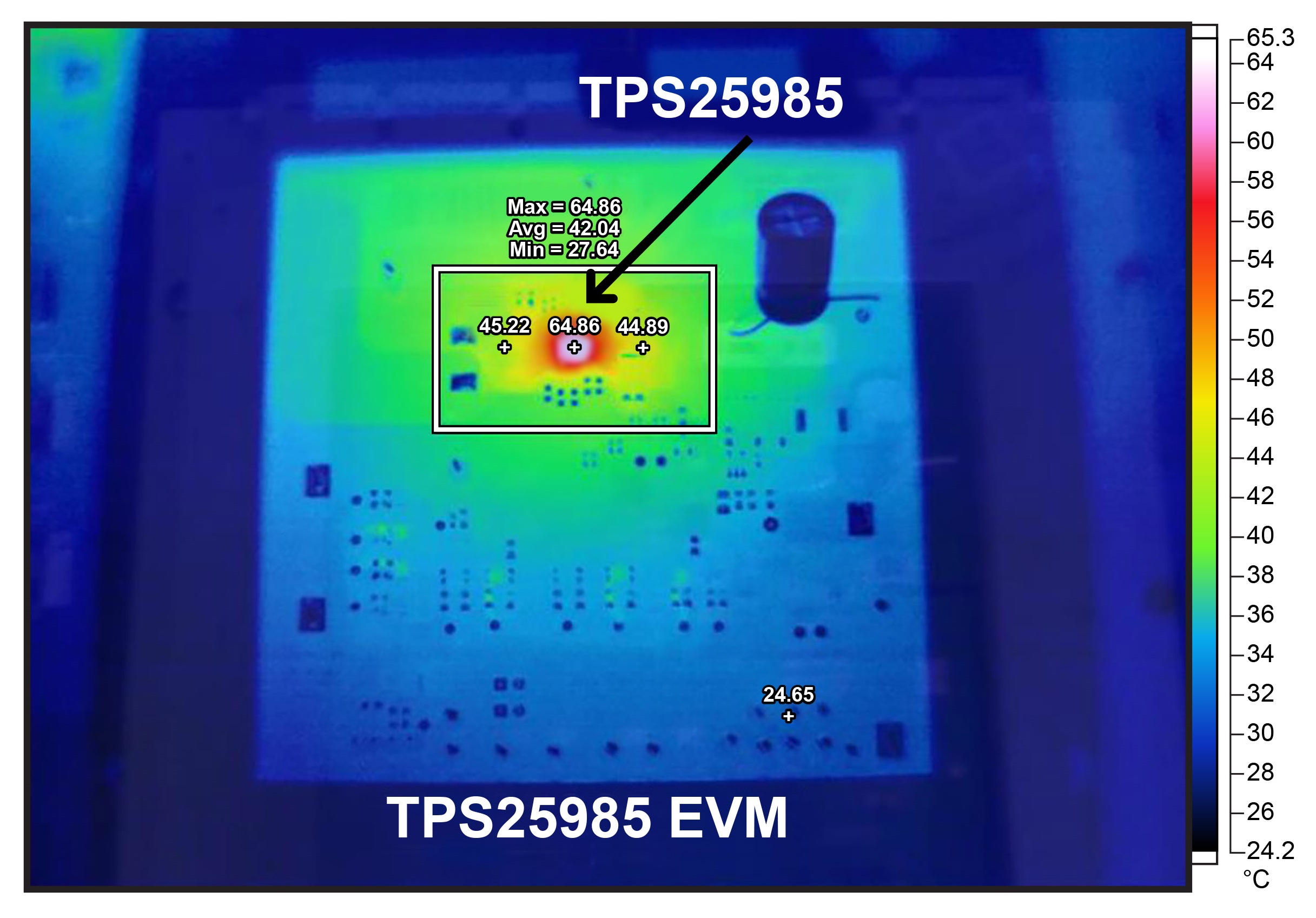

Server power systems operate at a wide ambient temperate range (–40ºC to 85ºC). Hot-swap controllers or eFuses experience even higher ambient temperatures. Therefore, power design engineers become concerned about the thermal performance of these devices when high currents are packed in small packages. The TPS25985 and TPS25990 eFuses alleviate this concern, with the ability to operate at a 125ºC junction temperature. The TPS25985 and TPS25990 offer an RDS(on) of 0.59 mΩ and 0.79 mΩ, respectively; RDS(on) spread across process, voltage and temperature variations is limited. Thus, these eFuses experience very low self-heating and a wide operating temperature range without sacrificing the derating. Figure 6 shows the case temperature of the TPS25985.

Figure 6 TPS25985 Case Temperature at vIN = 12 V, IOUT = 50 A, Tamb = 25°C

Figure 6 TPS25985 Case Temperature at vIN = 12 V, IOUT = 50 A, Tamb = 25°CConclusion

Design engineers can reduce development time and design cost by using the TPS25985 and TPS25990 eFuses in server power architectures. The eFuses’ low RDS(on) reduces power losses in the system, helping data centers achieve their efficiency goals. Improved power density improves data center processing capabilities and gives end users a seamless experience across their data-connected devices. Better diagnostic, scaling and configuration capabilities in eFuses can help data centers minimize downtime, which helps maintain continuity of service and their ability to offer customers high-percentage uptime guarantees.