SSZT081 april 2022 DRV8243-Q1 , DRV8244-Q1 , DRV8245-Q1

A brushed DC motor’s simplicity of control, low cost and wide range of capability makes it a good fit for automotive loads that need integrated, high-powered and reliable motor drivers such as window lifts, sunroof controls, locks, latches and engine valves.

If you’re designing an automotive system, you’ll likely encounter both device- and system-level challenges, including size constraints, fault conditions and the need for design reuse in order to reduce development time. So, in this article, I’ll break down these challenges and how to address them.

| Compact motor drivers offer detailed diagnostics and flexibility | |

|

Explore the DRV8244-Q1 mid-power brushed-DC integrated FET motor driver |

Reducing System Size with a Fully Integrated, Power-dense Motor Driver

Reducing system size and board space can be important factors to consider when designing a cost-optimized automotive system. Decreasing package size and integrating functionality into your brushed-DC driver to reduce external components can reduce board space and cost.

Consider these improvements when designing a smaller system:

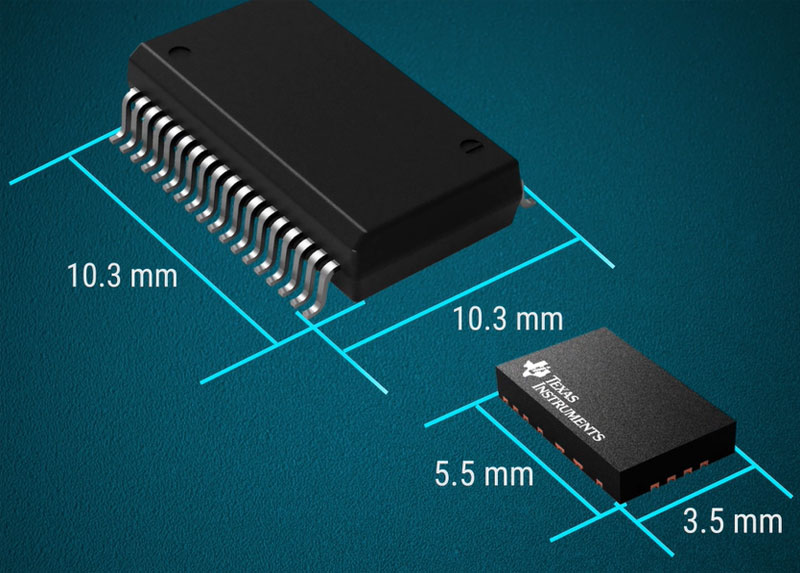

- A small package size – for a power-dense solution, use a small package size that also has a high current capability. The DRV8243-Q1 family introduces an automotive HotRod™ quad flat no-lead package as small as 3 mm by 4.5 mm, making it one of the smallest packages for brushed-DC drivers in its class.

- Integrated current sensing – internal current regulation and a current feedback pin eliminate the need for external current-sense resistors, reducing board space and cost.

- An integrated field-effect transistor (FET) solution – the DRV8243-Q1 family can drive up to 32-A peak currents for H-bridges and 46-A peak currents for half bridges. With an integrated solution that supports mid- to high-range currents, you can save board space and cost by eliminating the need to use a gate driver plus external FETs. Current capability depends on the printed circuit board design and ambient thermal conditions, so make sure to check out our Transient Thermal Calculator to understand what currents can be driven in your system.

Using smaller packages (as shown in Figure 1) and minimizing the number of external components enables you to decrease the size of your board, as well as your bill-of-materials cost.

Figure 1 DRV8245-Q1 Device Family Size

Comparison

Figure 1 DRV8245-Q1 Device Family Size

ComparisonProtection and Diagnostics for a Reliable Solution

The role that motor drivers play in applications, from power lift gates to gas engine valves, makes it important to design a reliable solution that detects and protects against various fault conditions.

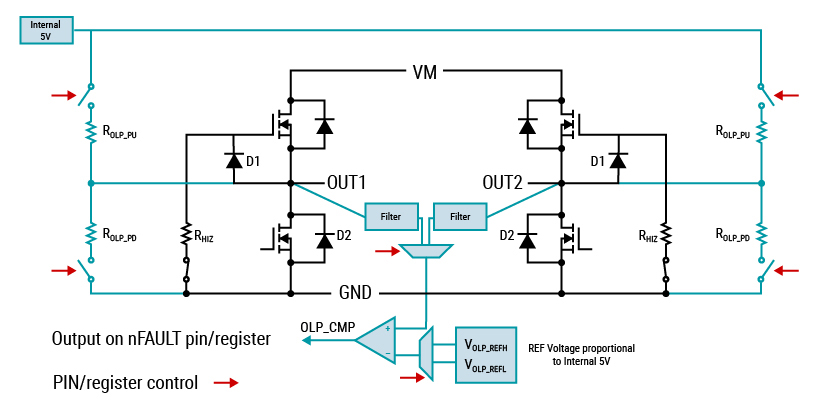

The DRV8243-Q1 device family is among the first to offer open-load detection and short-circuit protection when the motor driver is both in the on and off state. Figure 2 shows how the device’s offline protection feature uses a network of passive resistors connected to the H-bridge to detect system issues before enabling the FETs. This feature helps motor drivers avoid damage or unexpected behavior even when the H-bridge is in the off state.

Figure 2 Off-state Diagnostics for the

DRV8243-Q1

Figure 2 Off-state Diagnostics for the

DRV8243-Q1Offline diagnostics are beneficial for protecting the motor driver from faults that occur elsewhere in the system from overall wear and tear. Read more about how TI’s offline protection features protect your automotive system in the application note, "Open Load Detection in Motor Drivers"

A Serial Peripheral Interface option provides detailed diagnostics to identify the type of fault and its location, saving designers time fixing motor-driver faults by pointing them to the source of the problem.

Optimizing Design Time with Scalable Drivers

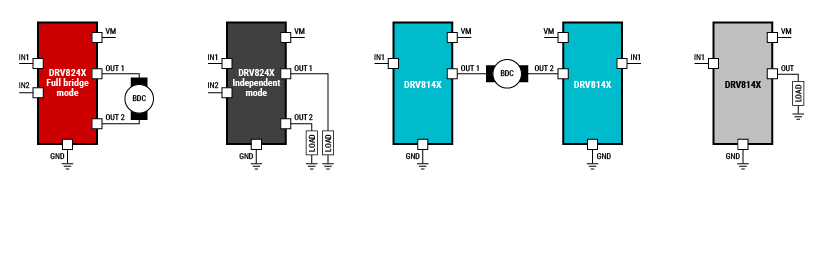

Motor drivers drive a variety of loads in cars such as relays, solenoids and motors. All of these loads sometimes exist within the same application, such as door modules or body control modules.

The DRV8243-Q1 family’s H-bridge and half-bridge drivers enable you to reuse your designs in order to scale across different loads in automotive systems. With similar firmware, features and package pinouts, this device family can help reduce design time by enabling reusability across various loads and current ranges. When used in independent mode, the H-bridge driver can drive two unidirectional brushed-DC motors, solenoids or relays, eliminating the need for two separate half-bridge drivers; see Figure 3.

Figure 3 Scalability across Various Loads with DRV8243-Q1 Family Variants

Figure 3 Scalability across Various Loads with DRV8243-Q1 Family VariantsIn addition to having similar firmware, the DRV8243-Q1 and DRV8244-Q1 leaded packages are pin-to-pin compatible, making it even easier to drop in and replace these devices when scaling up or down in power levels.

Solution size, protection and design reuse are critical factors to take into consideration when designing automotive solutions. If you have any questions regarding the topics covered in this article, I encourage you to ask a new question in the TI E2E™ Motor Drivers forum.

Additional Resources

- Read the technical article, "Benefits of flip chip on leadframe packaging for motor-drive applications."

- To learn more about the benefits of integrated current sensing, see the application brief, "Advantages of Integrated Current Sensing."

- Read more about how TI’s offline protection features protect your automotive system in the application note, "Open Load Detection in Motor Drivers"

- Read the application note, "Using Motor Drivers to Drive Solenoids"