SSZT345 February 2020 DAC11001A , DAC91001

Even when selling hundreds, thousands or even millions of products, many companies individually mark every single unit they sell with a brand or logo. The task of marking brands and etching logos is performed by laser marking machines, and the process requires a very high level of precision. As the technology progresses, designers of these systems are under pressure to make laser marking machines even more accurate so that more detailed markings are possible.

A laser marking machine (Figure 1) uses a high-intensity, low-power laser to etch a very precise design on anything from a cellphone to something like hand tools and printed circuit boards (PCBs). To create the desired output, the laser needs to be very carefully guided with the help of a precision digital-to-analog converter (DAC).

Figure 1 A Laser Cutting

Machine

Figure 1 A Laser Cutting

MachineSo how does the DAC contribute to controlling the laser? The DAC is responsible for providing a very precise output voltage, which is then used as the analog input for a motor. Each specific analog input code from the DAC is related to a specific motor position. This motor is responsible for moving a mirror, which can be repositioned in the x, y or z planes to guide and reflect the laser and position it on the end equipment, where it can then alter the material’s surface and etch a logo, text or barcode. See Figure 2.

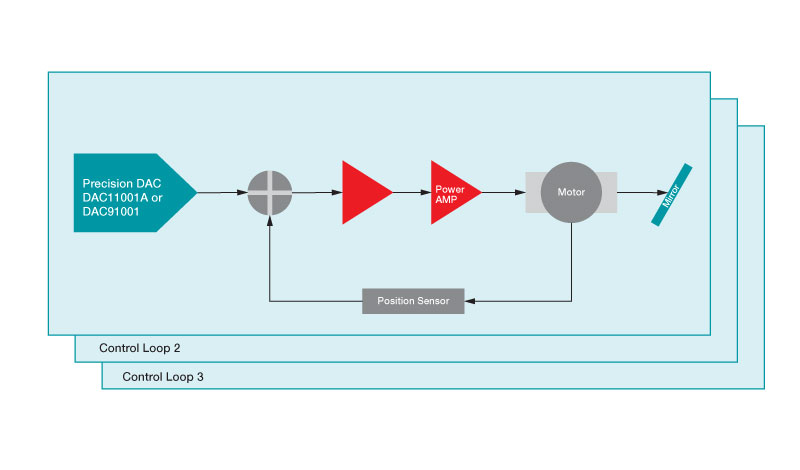

Figure 2 TI’s DAC11001A Providing an

Output to the Analog Motor-control Loop

Figure 2 TI’s DAC11001A Providing an

Output to the Analog Motor-control LoopAs products that require etching become smaller, such as PCBs and some consumer goods, the precision of a laser marking system must increase. TI’s DAC11001A and DAC91001 offer 20-bit and 18-bit resolutions, respectively. These resolutions are important because they translate to the number of voltage steps available at the output of the DAC. An 18-bit resolution, for example, would have 262,144 unique codes (see Table 1), allowing for that many motor positions to control the laser. A 20-bit DAC offers 1,048,576 unique codes, providing far more granularity and far more precision.

| 16-bit = 216 = 65,536 (0 to 65,535) |

| 18-bit = 218 = 262,144 (0 to 262,143) |

| 20-bit = 220 = 1,048,576 (0 to 1,048,575) |

What other benefits come with laser making systems utilizing 20-bit DAC performance? Well, if a full turn of the motor equates to 1 radian, what kind of step size do you need? Existing systems have a resolution of about 10 microradians for around 1 radian full-scale range. This equates to a resolution of 18 bits, ideally, but with system-level nonlinearity, many designers desire 20-bit resolution. This is where DAC11001A can help by offering nearly four times the number of output codes, and by extension, even finer control of the motor.

Another concern to consider is motor vibration. Any glitch in laser marking systems can adversely affect the final etching. These systems are very sensitive to residual motor vibration because the control loop has a multiple-order transfer function. Designers use complex techniques to achieve better performance, from selecting a low vibration motor to using complex control system logic. One of the key causes of motor vibration is the code-to-code glitch from the DAC. DAC11001A and DAC91001 have a very low code-to-code, code-independent glitch of 1nV-s. This is achieved through an integrated track-and-hold circuit that isolates the output of the DAC from the inherent code-to-code glitch of the internal resistor ladder.

As we have seen, laser marking machines have to contend with many variables with trying to achieve high precision. The DAC plays a pivotal role in solving this problem and can make a designer’s work much easier. Innovative solutions that offer higher resolution for increased accuracy and better glitch performance can make all the difference in laser marking designs.

Additional resources

- Check out the application brief, “DACx1001 Enables Ultra-High-Precision Closed-Loop-Control System Design.”

- Explore other TI solutions for laser system design.