SSZT827 January 2018

A Google search for the term “analog to digital converter selection” produces thousands of hits, proof that this task continues to challenge a number of us involved in designing that elusive, perfect sensing solution. After all, there are a vast number of analog-to-digital converter (ADC) solutions out there, from simple 10-bit ADCs integrated in 8-bit microcontrollers (MCUs) to ADCs that can resolve at GHz rates.

Unless you are designing a specialized sensing front end, chances are you are looking for an integrated ADC capable of high-quality performance without compromising on energy savings or operational flexibility. In this post, I’ve outlined a few parameters that can help you narrow your search for ADCs, although you may have additional parameters depending on your application’s specific needs.

- Resolution. Perhaps the most debated ADC parametric, there are many questions around whether the number of bits an ADC can resolve is the most significant measurement of its accuracy. A simple way to look at it is by examining the actions your application will take following ADC conversion. For example, is it a relative measurement to measure whether a delta change in temperature has occurred? If so, a 10-bit or 12-bit ADC may suffice, since that is a true-false-no question. On the other hand, consider a product such as an electricity meter. In this application, the analog-to-digital conversion requires a high level of precision The accuracy of the load current measurement could mean a difference in energy usage and thus billing for the utility company. Such applications typically use >16-bit delta-sigma ADCs, ensuring a high quality of conversion results.

- Sample rate. The sample rate of the ADC directly depends on the frequency of the input. Thanks to our scholarly friend Nyquist, you know that ADCs must sample at >2x the input signal (Fsample ≥ 2x Finput), and you know that there is a minimum required sample rate. For example, a 100kHz input will need to be sampled at ≥200kHz. However, the sample rate specified in the data sheet covers only true “sample + conversion” clocks – and does not take into account any setup time for the ADC, post-processing converted results for decision-making or moving data off-chip. These factors are equally important because they enable you to calculate the period and duty cycle of ADC conversions, and hence the remaining margin for post-processing.

As an example, an ADC sampling at 1MSPS will collect 1,000 16-bit samples in 1ms. If you used a double-buffered approach to capture the ADC samples, then you know that you have ≤1ms to post-process the data buffer, take actions based on the results and possibly move the data before the next data set is ready for processing.

- Reference selection. An important criterion when evaluating integrated ADCs is the availability of an internal precision reference source. In some cases, the ability to set up multiple reference voltage ranges ensures flexibility in resolving different input ranges of the ADC.

- Operating range. Many ADCs operate for a limited portion of the total supply-voltage range available to the device. It is important to gauge the application’s needs in this regard. For example, in battery-operated applications, it may be necessary to go down to the full minimum supply range (1.8V is fairly typical for MCUs, although some ADCs like the one in TI’s SimpleLink™ MSP432P4 family can operate down to 1.72V) to ensure reliable conversions until the device shuts down.

- Input channels. The number of input channels is not just the number of externally available pins available to interface to analog inputs. When selecting an ADC for a group of inputs that require sequencing, it is also important to consider the flexibility of the channel configuration. Selectable reference sources, dedicated interrupts and conversion registers, and the availability of differential inputs and configurable data formats are important capabilities to ensure that you can set up the ADC configuration efficiently and in a way that’s customizable, preventing wasted cycles on setup.

As I mentioned at the beginning of this post, your actual list of ADC selection criteria may be much longer depending on what the application is trying to sense. You can evaluate the MSP432P4’s high-performance ADC with up to 16-bit precision by purchasing the MSP432P4 LaunchPad™ development kit and by taking a quick online tutorial on utilizing the precision ADC through our SimpleLink Academy training portal.

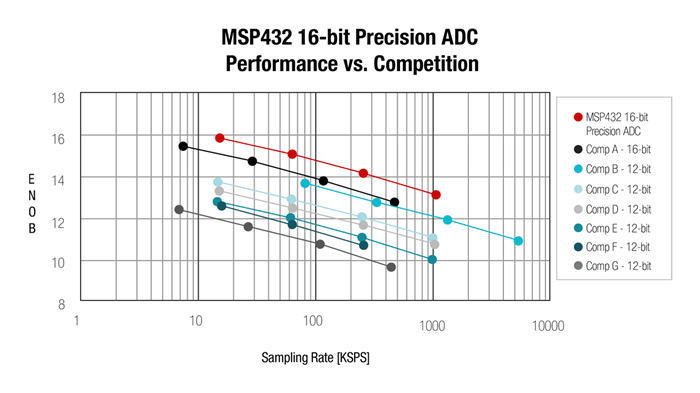

If you’d like to delve deeper into the topic of ADC selection and see how TI’s MSP432P4 high-precision ADC stacks up next to available ADCs on the market, take a look at the chart in Figure 1 below and check out our application report with useful hints on demystifying ADC data-sheet parameters.

Figure 1 Performance of MSP432 16-bit Precision ADC compared to competition

Figure 1 Performance of MSP432 16-bit Precision ADC compared to competition