SSZT868 january 2030 TPS92830-Q1

The evolution of automotive lighting has spanned decades. In the age of light-emitting diode (LED) lighting, expectations for complete lamp designs have never been higher; these expectations are increasing the technological evolution of LED drivers in the semiconductor industry. Today, automotive lighting requires a high-quality homogenous design to realize superior effects not only in headlamps, but also in rear lamps.

Figure 1 Automotive Head Light and Rear

Light

Figure 1 Automotive Head Light and Rear

LightIn the past, the way to achieve greater brightness was to increase the number of LEDs. But if you tear down a new rear lamp now, you will see more light guides, light pipes, light shields and other complicated lighting structures to achieve smoother lighting effects. With the changes above, fewer LEDs but higher current of each LED will be required.

Designers use switching-type LED drivers to drive a high current for each LED. But in automotive rear combination lamps (RCLs), the high switching frequency may interfere a lot with antennas, causing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues. When using linear LED drivers, high power dissipation inside the LED driver itself could potentially affect the life of the entire lamp.

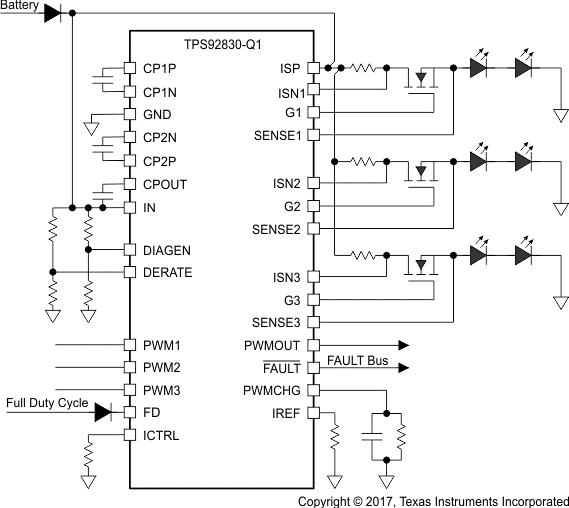

TI has a new three-channel, high-side, constant-current automotive linear LED controller that can help solve these problems. Figure 1 shows a schematic of the device, the TPS92830-Q1.

Figure 2 TPS92830-Q1 Simplified

Schematic

Figure 2 TPS92830-Q1 Simplified

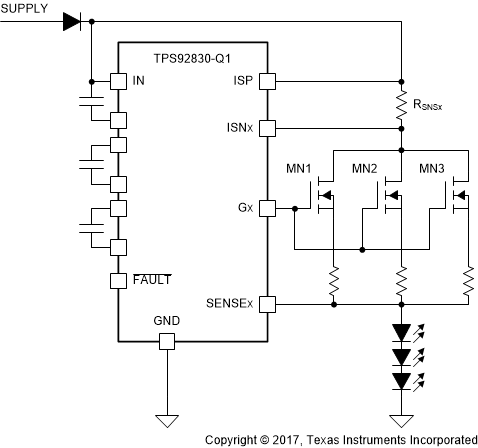

SchematicTI removed the metal-oxide semiconductor field-effect transistors (MOSFETs) inside of the device in order to let you make the decision as to what type of MOSFET you need for the whole RCL system according to the actual output current. This way, you can design more complex rear lamps by using one or two pieces of TPS92830-Q1 combined with external high-current MOSFETs to deliver up to 250mA or 300mA per channel.

This innovation also releases the heat of the device itself to optimize overall system thermal performance. Because of this innovation, you can use the TPS92830-Q1 to drive stoplights, taillights, turn lights, position lights and even daytime running light (DRL)s. It depends on how big the external MOSFETs you will need for your design.

Figure 3 MOSFET Parallel Driving

Support

Figure 3 MOSFET Parallel Driving

SupportMeanwhile, TPS92830-Q1 also integrates a high-precision on-chip pulse-width modulation (PWM) generator. It’s very accurate that the tolerance is as low as 2% which leads the industry and helps you achieve a high-quality homogenous design on each lamp. It’s very suitable for a design to have separate lamps on the trunk and the fender. The difference in the brightness of the two lamps is undetectable to the human eye. You can choose between the on-chip PWM signal and external PWM signal according to the system architecture.

The device has full advanced protection and detection features to ensure that your design meets all car original equipment manufacturer (OEM) requirements such as LED open, LED short and one-fails-all-fail. The TPS92830-Q1 also supports current derating function, which protects external MOSFETs under high input-voltage conditions to ensure system reliability.

Comment below to tell us what you think!

Additional Resources:

- Learn more with the data sheet: How to Select MOSFET for TPS92830-Q1 Circuit

- Watch this video to learn more about the TPS92830-Q1 EVM.

- Visit the TI E2E™ Community Power Management forum to search for solutions, get help, share insights and more!

- Learn more about TI’s Body Electronics & Lighting systems