SSZTA07 June 2018 LM53625-Q1 , LM53635-Q1 , TLE4275-Q1 , TPS7B63-Q1 , TPS7B67-Q1 , TPS7B68-Q1

A system basis chip, or SBC, is an integrated circuit (IC) that combines many typical building blocks of a system including transceivers, linear regulators and switching regulators. While these integrated devices can offer size and cost savings in a number of applications, they don’t work in every case.

For applications where an SBC isn’t a good fit, it might be beneficial to build a disc rete implementation of these aforementioned building blocks, and that is what I mean by the term “discrete SBC.” In this post, I’ll describe some scenarios where building discrete SBCs can solve system requirements, and what additional benefits you’ll gain by using discrete solutions.

Versatile Power Topologies

Figure 1 Boost Regulator Followed by Buck Regulator Topology

Figure 1 Boost Regulator Followed by Buck Regulator TopologyWhile this solution requires two regulators, the additional benefits are:

- You can choose the intermediate voltage such that you can regulate multiple output rails from it. Active antenna applications often require regulated voltages from 7V to 12V; Controller Area Network (CAN) transceivers require 5V; and microprocessors typically need 5.0V, 3.3V or 1.8V. By choosing your intermediate voltage above the highest required regulated output voltage, you eliminate the need for a second boost regulator inside the module.

- In applications like eCall, where a module must operate through brownout conditions or a complete battery-disconnect condition for a given amount of time, you can set the intermediate voltage to a higher voltage to store more energy in the output capacitance of the regulator. The total energy stored in the output capacitance, which in this scenario is also acting as the hold-up capacitance during brownout or battery-disconnect scenarios, is equal to . As you can see, the energy is proportional to the square of the stored voltage, which means that if the intermediate voltage doubles, the total energy stored quadruples, thus making it easier to ride through brownouts or maintain operation longer after battery disconnect.

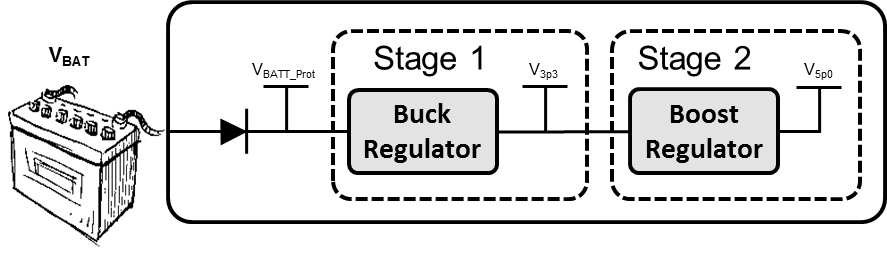

In my second example, a discrete SBC solution may be beneficial in nodes that need to operate through start-stop transients where battery input voltages can dip down as low or lower than 5.5V. If the module requires both a regulated 5V supply for a CAN transceiver and a 3.3V regulated supply for the microcontroller, a wide-input-voltage buck converter set to 3.3V followed by a small low-input-voltage boost converter can be a competitive solution. Figure 2 shows this topology.

Figure 2 Buck Regulator Followed by Boost Regulator Topology

Figure 2 Buck Regulator Followed by Boost Regulator TopologyThe additional benefit here is that since the battery’s input voltage immediately bucks down to a regulated low voltage, it only requires one wide-input-voltage regulator. Therefore, the 3.3V to 5.0V boost regulator can be a low-input-voltage, low-current device, saving cost.

Scalable Product Families and Controller Products

- Buck regulators:

- LM53625-Q1 and LM53635-Q1 families (2.5A/3.5A).

- TPS57040-Q1/57140-Q1/54240-Q1 families (0.5A/1.5A/2.5A).

- Linear regulators (LDOs):

- TPS7B63-Q1 and TPS7B68-Q1 watchdog LDO families (300mA/500mA).

- TPS7B67-Q1 and TLE4275-Q1 450mA LDO families, with and without low power mode.

Devices within each of these families are pin-to-pin equivalent and interchangeable with one another depending on your design’s load current or feature requirements. And because both buck and boost regulators have controller products that use external field-effect transistors (FETs) and diodes, you can easily scale these products depending on the load-current requirements of each design variant.

While not all applications have the same requirements as the two examples I’ve described here, being willing to look at discrete solutions offers superior flexibility and scalability.

As always, log in and leave a comment if you have any questions or topics you would like to hear more about.

Additional Resources

- Download these TI reference designs: