SSZTAQ6 october 2016 TPD4E02B04 , TPD6S300 , TPD8S300 , TPS65983B

By now, many people have heard of the USB Type-C connector. At a high level, it’s a new connector defined by the latest USB standard that combines power delivery, data, audio and video into a single reversible connector. Sounds simple enough, right? However, what seems simple and flexible to consumers has added design challenges on the engineering side. In this post, I’ll describe the challenges associated with protecting the USB Type-C connector using discrete components.

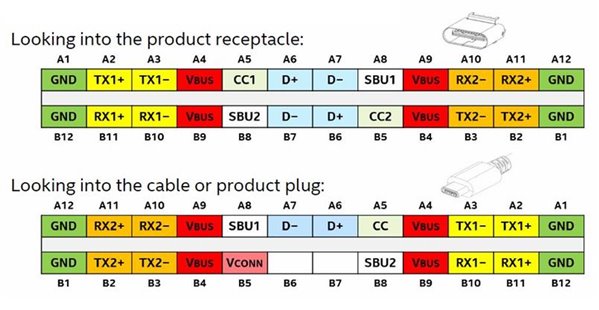

The USB Type-C connector differs from its older counterparts, Type-A, Type-B, Micro-B, in many ways. The connector is symmetrical and enables reversible plug orientation in a 24-pin, 8.4mm-by-2.6mm form factor. Unlike previous connectors defined by the USB standard, which can only deliver power up to 2.5W (USB 2.0) or 5W (USB 3.0), USB Type-C can deliver up to 100W, enabling many fast charging applications while simultaneously delivering data across other connector pins.

I see two main challenges associated with USB Type-C protection:

- A small pin pitch

increases risk of short circuits. To support all of this

functionality in such a small form factor, the pin pitch of USB Type-C

connectors is 0.5mm, which is much smaller than the 2.5mm pin pitch in the

USB Type-A connector. This tiny pin pitch increases the likelihood of a

pin-to-pin short circuit. If debris becomes caught in the connector, or if

the consumer pulls the connector out of the receptacle at an angle, a short

could easily occur. These shorts are especially devastating for the sideband

use (SBU) and configuration channel (CC) pins, which are directly adjacent

to the VBUS pins, shown in Figure 1, and are only tolerant to 5V. The VBUS lane

can deliver up to 20V and 5A for 100W fast charging power delivery, as I

mentioned, which could seriously damage the sensitive components connected

to the SBU and CC pins.

Figure 1 USB Type-C

Connector Pinout

Figure 1 USB Type-C

Connector Pinout - Noncompliant cables and adapters risk damaging internal circuitry. In a survey of USB Type-C cables available on Amazon, 28% of cables were not compliant to the USB interface specification. Although faulty cables have been banned by some sellers, the risk that users will purchase faulty or non-compliant cables still exists. Thus, the system must include overvoltage protection in addition to standard electrostatic discharge (ESD) protection. Noncompliant cables are not the only source of worry, either. There are noncompliant power adapters that put out 20V onto the VBUS path without proper USB Power Delivery (PD) negotiation. If the system is designed to handle only 5V, or if the CC pins were pulled up to the VBUS rail, the downstream circuitry could be permanently damaged.

Two Approaches to USB Type-C Protection Challenges

For more detailed information about USB Type-C protection, see the white paper, “Circuit Protection for USB Type-C™” or the additional resources below.

Additional Resources

- Start designing now with the TPD8S300 evaluation module.

- Learn more about the TPS65983B USB Power Delivery 3.0 controller.

- Check out the TPD4E02B04 device for high-speed data-line ESD protection.