SSZTBL2 february 2016 AM3356 , AM3359

This is the fourth installment of “How to select the right industrial Ethernet standard,” a series for designers who have decided to leverage industrial Ethernet in their systems. In this series, I’m covering several common industrial Ethernet communication protocols to help you select the right standard for your application. In my previous posts, I discussed EtherCAT, Sercos III and PROFINET.

Today, let’s look at the EtherNet Industrial Protocol (EtherNet/IP or EIP), one of the top five industrial Ethernet standards for factory-automation and process-automation applications. This industrial Ethernet standard is common among manufacturers in the United States. It was initially developed by Rockwell Automation and is now part of the International Electrotechnical Commission (IEC) 61158 standard. Introduced in 2001, the EtherNet/IP standard is now under the umbrella of the Open DeviceNet Vendor Association (ODVA), an organization that drives the specification and coordinates conformance testing.

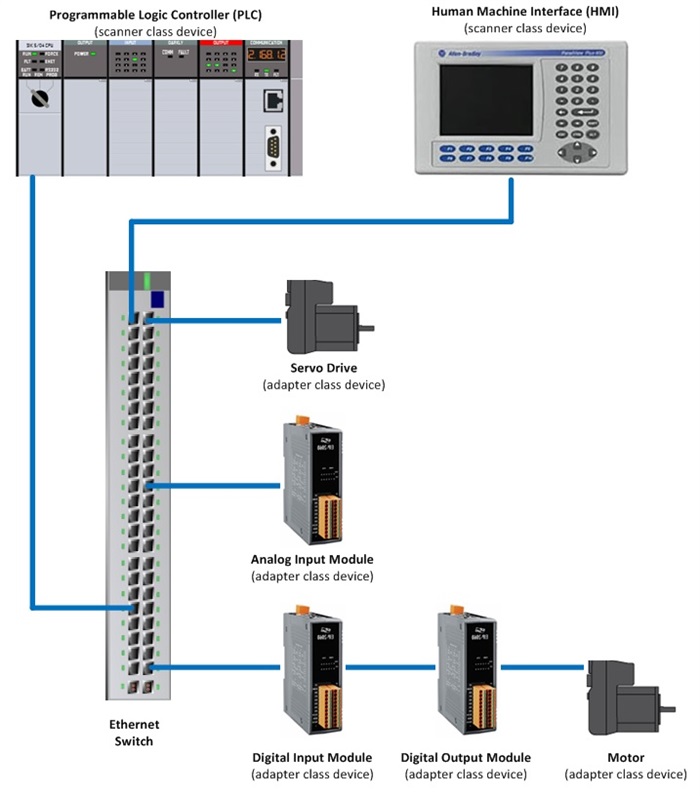

EtherNet/IP has a consumer and producer network hierarchy, whereas the devices/components are called input/output (I/O) scanner and I/O adapter. There is also explicit message server and explicit message client, but I will not discuss those in this post.

The I/O scanner sets up communication with the I/O adapter and exchanges process data with it. The I/O scanner is responsible for the operation parameter configuration of the I/O adapters. A typical example of an I/O scanner is a programmable logic controller (PLC) or a human machine interface (HMI).

The I/O adapter generates I/O data at a data rate controlled by the I/O scanner. An I/O adapter can be a digital and/or analog I/O device, or something more complex such as a motor drive or modular pneumatic-valve system.

EtherNet/IP is very flexible in terms of network topology because it’s based on the 802.3 Ethernet standard. Network topologies include line topology, ring topology, star topology or any combinations of these using hub and switch devices – see Figure 1. It supports 100Mbps, 10Mbps or a combination of the two.

Figure 1 EtherNet/IP Network in an

Automation System

Figure 1 EtherNet/IP Network in an

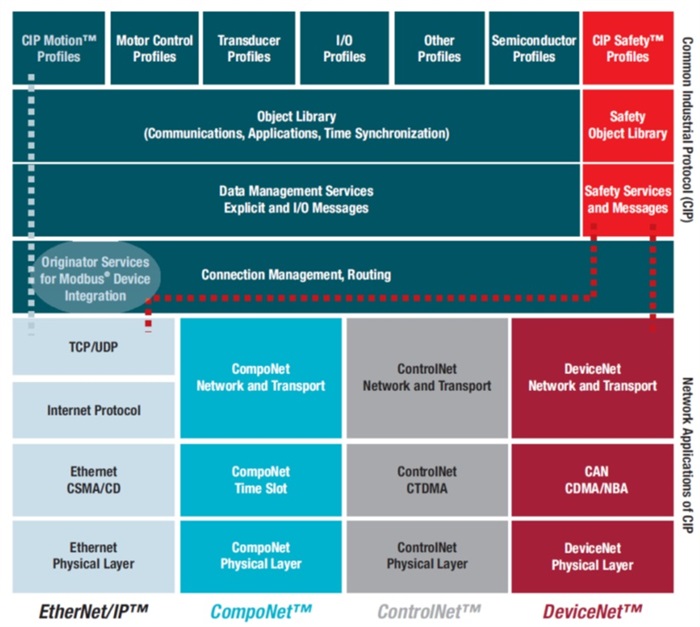

Automation SystemEtherNet/IP is part of a family of network protocols that use the Common Industrial Protocol (CIP) as the upper layer (see Figure 2). Other industrial protocols using CIP include DeviceNet, CompNet and ControlNet. Operators/engineers already familiar with DeviceNet or ControlNet should have no problem becoming familiar with EtherNet/IP. You can also use configuration tools for other CIP family members with EtherNet/IP.

Figure 2 DeviceNet, CompNet and

ControlNet Share the Same CIP Application Layer with EtherNet/IP

Figure 2 DeviceNet, CompNet and

ControlNet Share the Same CIP Application Layer with EtherNet/IPAnother benefit of EtherNet/IP is that it uses Transmission Control Protocol/Internet Protocol (TCP/IP) and User Datagram Protocol/Internet Protocol (UDP/IP). EtherNet/IP uses TCP frames for configuration and messaging and UDP frames for real-time process data.

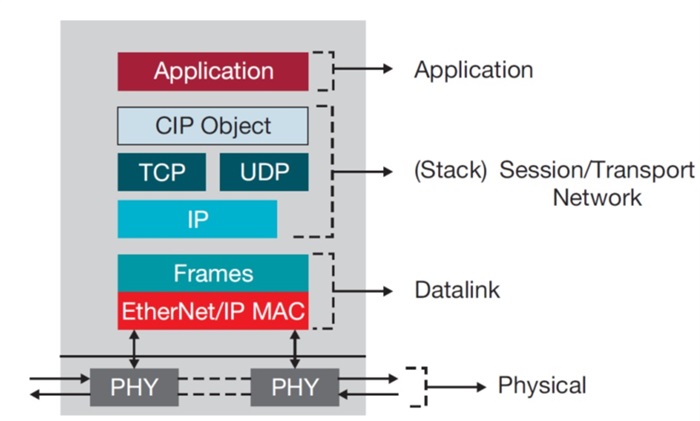

Because EtherNet/IP is based on the 802.3 Ethernet standard and uses TCP and UDP frames, you can implement it with standard hardware components such as Ethernet network interface cards (NICs). However, to reduce network jitter and improve performance – especially in a line topology – the use of a cut through Ethernet media-access-control (MAC) is required (EtherNet/IP MAC, see Figure 3). This means that the EtherNet/IP MAC analyzes the incoming Ethernet frame for its destination address. Based on the destination address, the EtherNet/IP MAC will immediately forwarded the frame to the second Ethernet port when the destination address is a broadcast or multicast, or does not match with the switch’s MAC address. In an efficient device, the Ethernet frame delay is less than 2ms.

Figure 3 EtherNet/IP Device

Figure 3 EtherNet/IP DeviceEtherNet/IP supports device-level ring (DLR), a cable-redundancy technology based on a ring topology. Each EtherNet/IP device sends out Beacon frames by default every 400µs to detect any ring break. In case of failure, a “ring supervisor” actively reconfigures the network by remotely opening or closing Ethernet ports on EtherNet/IP devices.

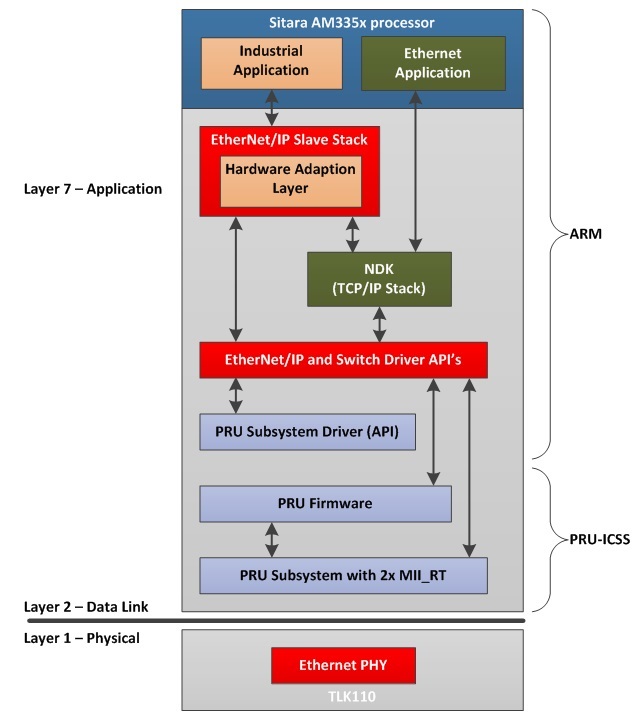

TI’s Sitara™ processors have a solution (see Figure 4) for EtherNet/IP supports cut-through switch technology with a unique programmable real-time unit and industrial communication subsystem (PRU-ICSS) peripheral. The solution has been conformance-certified by ODVA and was successfully tested at ODVA plug fests (a plug fest is a vendor meeting where they test device interoperability).

Figure 4 Software Architecture for

EtherNet/IP Slave

Figure 4 Software Architecture for

EtherNet/IP SlaveI hope I’ve shed some light into EtherNet/IP’s functionality. Make sure to read the other posts in this series to learn more about common industrial Ethernet standards.

Additional Resources

- Explore the development platform reference design for Ethernet/IP.

- Download the “Industrial Communication Solutions Guide.”

- Learn more about the EtherNet/IP standard on the ODVA website.