SSZTBP6 january 2016

Who Needs Industry 4.0 and What Is It about?

Being competitive in manufacturing goods requires continuous improvements in the production process. The efficiency and flexibility of manufacturers significantly improves by using information technology (IT). Providing a transparent and real-time view of the product life cycle can help manufacturers build the backbone of the framework of Industry 4.0. Running analytics in big data clouds helps to improve the process.

This high-level description raises a key question:

- Does it make sense to store all data from field level in big data cloud for analytics?

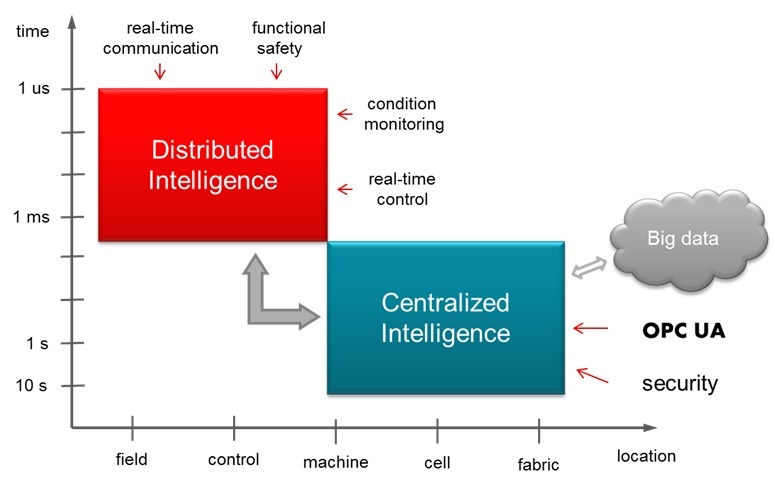

Processing of input/output (IO) data on manufacturing floor is too fast for big data analytics. Figure 1 shows the processing level over cycle time. Industrial communication and control used in factory automation is subject to cycle times as low as 31.25µs. Position data of products and equipment is captured every 10µs. Oversampled current measurement even goes below a 1µs sampling period. A fast-fourier-transform (FFT) analysis over current measurement and position measurement to detect harmonics can only be performed locally. The intelligence of real-time applications in the field remains with the I/O device and is not processed in a big data cloud.

Figure 1 Intelligence in factory

automation

Figure 1 Intelligence in factory

automationThe primary reason for the distributed intelligence is a lack of real-time deterministic communication of IT. Standard Ethernet and wireless Ethernet is best effort communication with no guarantee of real-time delivery through a network. The Internet protocol foresees retransmissions in case data did not arrive within expected time window. We have all experienced occasions when the Internet is sometimes slower than expected. The non-deterministic behavior of the Internet is an effect that asks for a separation of real-time communication and control on the field level and IT-based communication.

The Industry 4.0 Gateway Is Real

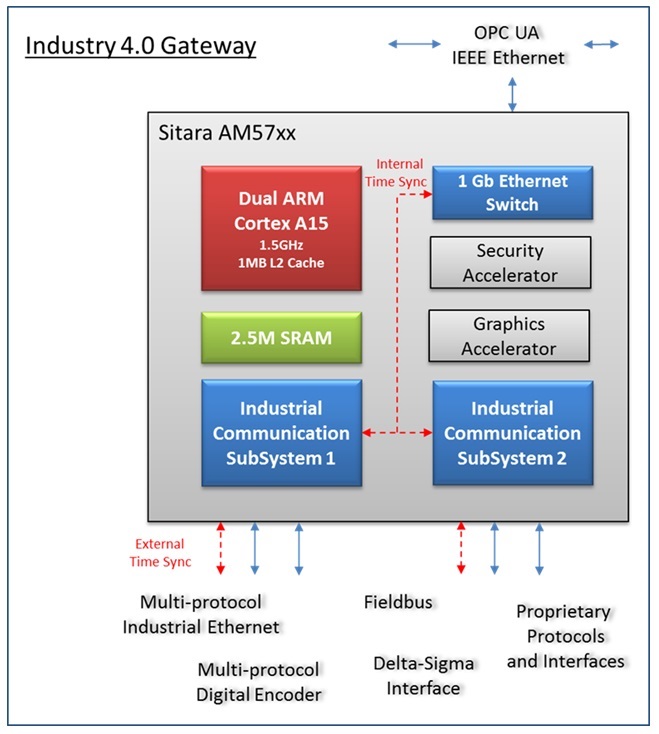

The Industry 4.0 gateway connects many proprietary interfaces on the field level with higher-layer functions of the manufacturing process. Any access point of IT-based communication requires security and a communication standard like Open Platform Communications Unified Architecture (OPC UA), which has all of the components for transparent and safe machine-to-machine communication. While real-time Ethernet synchronizes I/Os with jitter less than 100ns, the communication at the IT level has time synchronization accuracy in the range of seconds.

For a factory-wide view of events in the production system, time-stamp accuracy in the range of milliseconds is good enough. In the scope of plants and other product life-cycle elements, real time is defined in seconds.

Figure 2 gives an example of an Industry 4.0 gateway based on a Sitara™ AM57x processor. It has all of the elements needed to connect manufacturing floor with higher-layer functions of the production process.

Figure 2 Industry 4.0 gateway

Figure 2 Industry 4.0 gatewayGetting all sensor data to the cloud is not applicable for factory automation. The right level of data to object translation is needed to avoid congestion and the Industry 4.0 gateway is the key element for IT to access manufacturing process information.

Reaching field-level data directly requires the Internet to go real time with quality of service. A new Ethernet standard called Time-Sensitive Networking is in the works to add more real-time capability.

I am wondering what we will call the industrial Internet when it gets real-time capable for machines. Still Industry 4.0?

Additional Resources:

- If you weren’t able to attend SPS IPC Drives 2015, download presentation material from the show.

- Download programmable logic control (PLC) or industrial communication solution guides.