SSZTC36 october 2015 TPS2561A , UCC24610 , UCC28700 , UCC28730

I remember only a few years ago a USB wall outlet in an airport was a rare sight. Today, built-in USB chargers are more and more popular, even popping up in coffee and restaurant chains. New houses are now constructed with USB wall chargers, while existing home renovations now include replacing old AC receptacles with USB chargers. It is evident that adapter-free charging provides the convenience of fast charging, and also reduces clutter.

Figure 1 Built-in USB Ports on Airport

Terminal Seats

Figure 1 Built-in USB Ports on Airport

Terminal SeatsGiven the increasing adoption of USB wall chargers, I would like to offer some observations about basic design challenges and considerations. The most unusual challenge is how to meet stringent thermal performance requirements to meet safety codes. Unlike external or portable AC/DC adapter designs, a built-in USB wall charger can only dissipate heat through the outlet’s safety cover. One- or two-gang boxes behind the cover are surrounded by heat-insulation material. The front-face cover cannot exceed 60oC. Figure 2 shows example of one gang box. It usually has dimension of 4”(L)x2.75”(W)x2.5”(D). The actual space for accommodating the AC/DC power solution is much smaller than what dimension data indicates. The reason is the wiring arrangement through back side and connecting to receptacles at the front side of one gang box.

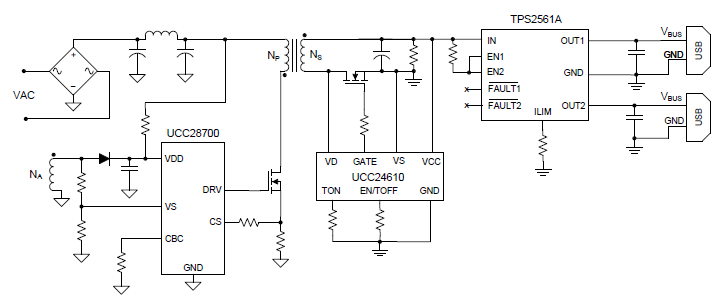

The maximum allowable amount of power dissipation behind the socket cover is 2-3W. For two 10W USB ports, you need 90% efficiency to control the loss to less than 2W. TI’s UCC28700 flyback controller and UCC24610 secondary-side synchronous rectifier can form a high-efficiency solution when used in commercially available USB charger/duplex receptacle. This receptacle offers two high-powered USB ports with 3.6A of total charging power, as shown in Figure 3. The power switch TPS2561A is used to provide dual USB outputs.

Figure 2 Typical One Gang Box behind

Wall Socket Plate.

Figure 2 Typical One Gang Box behind

Wall Socket Plate. Figure 3 USB Wall Charger

Implementation with Dual-outputs

Figure 3 USB Wall Charger

Implementation with Dual-outputsWith emerging applications like USB Type-C connector and USB-PD, consumers will look for charging powers above 20W, which can charge devices such as smartphones, tablets and ultrabook computers. Higher efficiency and a high-power-density AC/DC solution is a must for a USB wall charger. TI team is working on a high efficiency high density solution to meet this challenge.

The UCC28700 controller’s vampire power level is controlled to below 100mW. Although there is no industry regulation on standby power for USB wall chargers at the moment, I think that reducing standby power still has a noticeable impact on the world. For example, a 50mW vampire power reduction translates into power savings of 438Wh annually. TI’s UCC28730 flyback controller can even help achieve zero standby power (<5mW).

I expect more rapid adoption of USB wall chargers once USB Type-C supported devices become more mainstream choices. When hotels, airports, coffee shops, restaurants and homes are equipped with USB Type-C wall chargers, we will only need to carry one USB Type-C cable instead of different chargers for different electronic devices. As a frequent traveler, I hope that day comes soon. Where have you seen USB wall chargers?

Additional Resources

- Read more about achieving zero no-load power

- Learn more about USB Type-C