SSZTC49 september 2015 UCD90240

If you have not already designed a power supply using the PMBus™ digital interface or have not yet been exposed to PMBus, you may wonder what it’s all about. Here are some common questions and answers about PMBus.

Q: What is PMBus?

A: PMBus is an I2C-based communication standard for power-supply management. It’s owned and regulated by the System Management Interface Forum (SMIF); SMIF membership is open to everyone. PMBus specifications are also freely available. PMBus works with all types of power-management products, including AC/DC power supplies, hot-swap controllers, sequencers, isolated and bus converters, and point-of-load (POL) regulators.

Q: What are the basic PMBus requirements?

A: PMBus devices must start up safely without bus communications; they can be used with or without a power system manager/controller. They support a “set-and-forget” mode in which they can be programmed at the time of manufacture and then operate without any bus communication. The load default settings can come from hard-coded constants, pin programming (pin strapping through external analog components) or nonvolatile memory (NVM). The typical value load sequence is:

- Start

- Apply IC bias power; controller starts.

- Load hard-coded values, if any.

- Load pin programmed values, if any.

- Load values from DEFAULT store, if any.

- Load values from USER store, if any.

- Enable bus communication.

- Accept valid values from bus communications.

- Output enabled?

- If no, go back.

- If yes, start power conversion.

Q: What are some basic PMBus commands?

A: There are on/off control options like always on, respond to control pin and ignore operation command (or vice versa), or respond to both control pin and operation command. There are configuration commands to set the maximum output voltage, change the output voltage, margin it, set the maximum duty cycle, set the switching frequency, set the undervoltage lockout (UVLO), soft start and introduce turn-on/turn-off delays. There are calibration commands to tighten the output-current telemetry accuracy by inserting a fixed offset and gain. There are operational commands for sequencing, tracking and interleaving, and commands to write and read manufacturer data. Finally, there are data-security commands such as packet error checking (PEC) to help validate if data was written correctly into a device, and WRITE_PROTECT that prevents unwanted writes into a device.

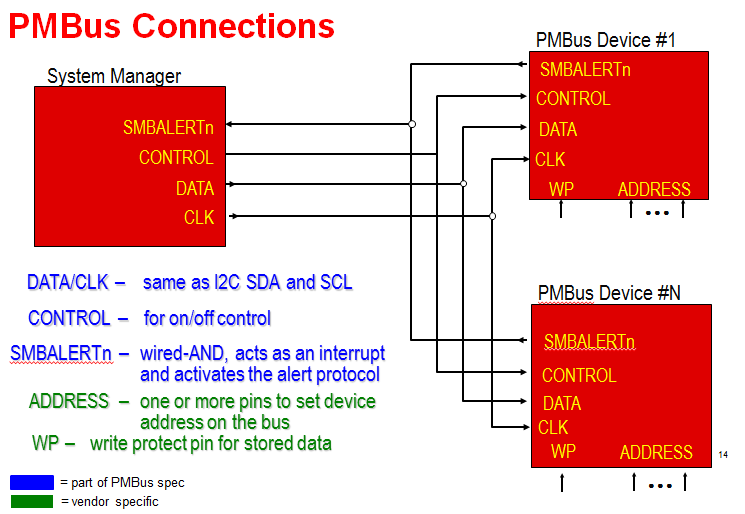

Q: What are the PMBus connections and protocol?

A: Figure 1 shows the PMBus connections.

Figure 1 PMBus Connections.

Figure 1 PMBus Connections.The protocol uses data transport based on SMBus v3.0 (PMBus v1.3). It uses standard command codes tailored to power-supply applications, and allows 400 KHz and 1 MHz clock. It has added group command, extended command, zone read, and write protocol. It is compatible with POL controllers including Intel serial voltage identification (SVID) controllers and controllers for other digital signal processors (DSPs) and central processing units (CPUs).

Q: Why do you need PMBus?

A: PMBus is easy to use in validation and in manufacturing environments. It enables you to quickly configure a power supply in a very short period of time, and allows customization by storing values into the device NVM. PMBus is ideal for active power management, which you need to achieve data center and cloud infrastructure power-usage effectiveness (PUE) of 1.0 by optimizing application-specific integrated circuit (ASIC) core voltages dynamically (adaptive voltage scaling [AVS]) in server, router, storage and switch boards.

PMBus can provide:

- AVS for reduced power usage.

- Multiple rail control for supply sequencing and reconfigurability.

- Power-supply monitoring for board-level power-use information fault monitoring and a dashboard for active data center management.

- Temperature information for load balancing and/or enhanced reliability.

- Easy board characterization – you can use telemetry to refine unknown parameters during test and qualification.

Q: How do you implement AVS through PMBus?

A: There are several methods:

- AVS through VREF_TRIM and MARGIN HIGH/LOW. Both the VREF_TRIM and MARGIN_STEP commands are relative to the device reference voltage. You need to scale the values by the resistor divider to reflect them at the output. For a 1V output, a 0.051V “margin” should result in 1V x 0.051V/0.6V (Vref), equaling a 0.085V change in the output voltage.

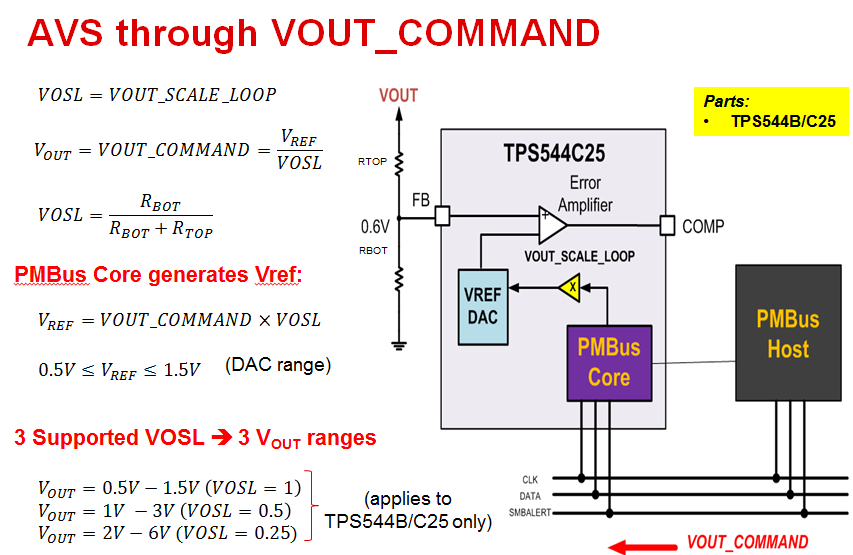

- AVS through VOUT_COMMAND. This is an absolute change in the output voltage. For voltage regulators that also use resistor dividers, set the output voltage Vout = VOUT_COMMAND = Vref/VOSL, where VOSL = Rbot/Rbot+Rtop (resistor divider). You have to select the VOSL range before you apply to the VOUT_COMMAND.

- AVS through PWM output. In this case, an injected current into the resistor divider changes the output voltage (Figure 2).

Figure 2 AVS through PWM

Output.

Figure 2 AVS through PWM

Output.Q: What power-supply parameters can you monitor through PMBus telemetry?

A: You can read the input/output voltage, current, power, internal/external temperature, storage capacitor voltage, fan speed, duty cycle, frequency and even the cumulative energy input/output in units of energy.

Q: Can you implement PMBus in manufacturing?

A: Yes. With TI’s Fusion Manufacturing graphical user interface (GUI), you can create PMBus scripts (the series of PMBus commands used in the program) and use the Fusion Command Line Tools or a third-party programmer to program the devices in high volume. If you prefer JTAG programming, there are JTAG-to-PMBus adapters for programming through JTAG. These essentially accept JTAG interface communication and have load devices like CPUs toggle the CLK/DATA lines on PMBus devices to emulate I2C communication, as described in a JTAG script. All of TI’s UCD9K sequencers support JTAG programming, except the UCD90240. TI’s PMBus SWIFT™ DC/DC converters and controllers also do not support JTAG; you would need a JTAG-to-PMBus adapter (what they support by default is SMBus/PMBus communication).

Q: What are some PMBus usage examples?

A: You can use PMBus in the lab for fast evaluation and prototyping without the need to solder resistors and capacitors to change the power-supply parameters. You can use it in the factory to customize the power system during manufacturing (setting the defaults of the power supply after board assembly) and during final system test. You can use it to create a dashboard for real-time and even remote monitoring through a remote host for field-unit diagnostics and management (through the RS-485 bus, for example).

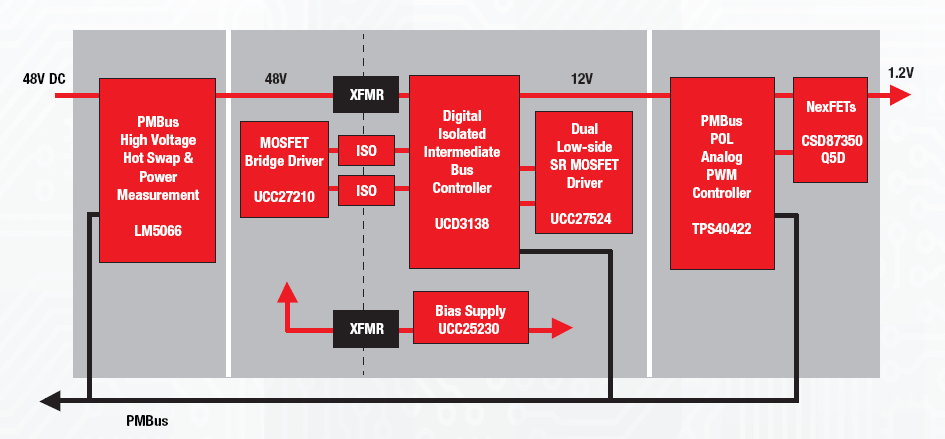

TI has a complete end-to-end PMBus power-management IC ecosystem. The example below shows power-supply demo board configurations from +/-48V DC to POL rail regulation.

Figure 3 TI 48V to POL End-to-end PMBus

Power System Block Diagram and Demonstration.

Figure 3 TI 48V to POL End-to-end PMBus

Power System Block Diagram and Demonstration.These were the nine things that I felt were important for you to know about PMBus. Did I miss a key question about PMBus? Please submit additional question in the comments section below and I’ll get back toyou.

Additional Resources:

- Get more information on TI’s products with PMBus at www.ti.com/pmbus.

- Order the SWIFT™ DC/DC converter evaluation module with PMBus at http://www.ti.com/tool/tps544b25evm-681 .

- Download TI’s Fusion GUI at http://www.ti.com/tool/fusion_digital_power_designer to configure and monitor digital power controllers and sequencer/health monitors.