SSZTCQ5 may 2015 TPS63060

Programmable logic controllers (PLCs) are more and more common in industrial automation systems. Controlling all sorts of machines in every conceivable manufacturing environment requires programmability for various functions, from moving the valves on a mixing tank in a chemical plant to controlling the speed on conveyer belts on a manufacturing line. The same PLC card can be used for multiple, different processes; the only difference is the programmed instructions on a given PLC unit.

The programmability and data retention of these programmed instructions sometimes requires a backup power source to store enough energy to properly power down the PLC during a sudden input voltage loss. Such a power loss occurs frequently in PLC cards which are hot-plugged into a rack-mount type of system.

In order to provide a proper power down, energy must be stored on the PLC card. The simplest way to do this is to take the input voltage and directly drive a capacitor bank. But, this requires a larger capacitor bank than what you’d need if the input voltage was boosted with the capacitors storing the energy at a higher voltage. Then, the system must also support operation at this higher, stored voltage, complicating the system design and increasing its cost.

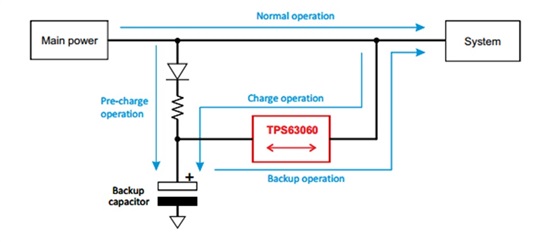

The PMP9761 TI Designs reference design provides a “both/and” solution to this dilemma. A buck-boost converter used bi-directionally boosts both the input voltage to the storage capacitors and steps down the capacitor voltage to the system. The system power supplies remain the same, with just the capacitor bank and buck-boost converter added to provide the backup function. This simple and straightforward implementation provides an essential function for some PLCs.

The same architecture is useful for any system that needs to properly shut down, even when their input supply voltage is removed, as well as for systems that need to ride through a brown out of the input bus. Such mission-critical systems might include medical devices, sensors and monitoring systems in a factory, or fail-safe user safety systems like conveyor belt disconnect devices. In these systems, reliable operation during input power transients is required or the system must enter a known safe state upon sudden removal of its power source. Storing energy in a backup power system is one method to achieve both of these goals.

Figure 1 The TPS63060 Provides Bi-directional

Operation for Systems Which Require a Backup Power Function

Figure 1 The TPS63060 Provides Bi-directional

Operation for Systems Which Require a Backup Power FunctionWhich of Your Systems Need to Store Energy to Properly Power Down?