SSZTCZ9 September 2023 ADS131B04-Q1 , ADS131M08 , AMC131M03

The electric vehicle (EV) charging industry is experiencing rapid growth. With consumers, industries and governments demanding more environmentally sustainable transportation, the EV charging infrastructure must become more efficient and accessible.

Unlike DC chargers, AC chargers do not use stacked power modules, making them more compact and less expensive. Their singular power-module architecture limits their use in public charging stations, as they cannot deliver the necessary amount of power in a reasonable time frame. Instead, their 22-kW charging speed makes them more suitable for residential EV charging, where consumers can accommodate longer charge times. They are also popular because some chargers only require a standard outlet. AC chargers use an EV’s onboard charging unit to convert AC power to DC power.

Stacked power modules in DC chargers provide faster charging times and charging speeds over 360 kW. The power modules reduce overall charge times but increase the size of the charger, making them more suitable for public charging stations than residential spaces. DC chargers convert AC power to DC power inside the charger, so the charger can connect to the battery directly.

Regardless of charger type, a highly accurate metering solution is important in order to ensure reliable energy measurements and calculations for system monitoring and billing.

Metering in EV chargers

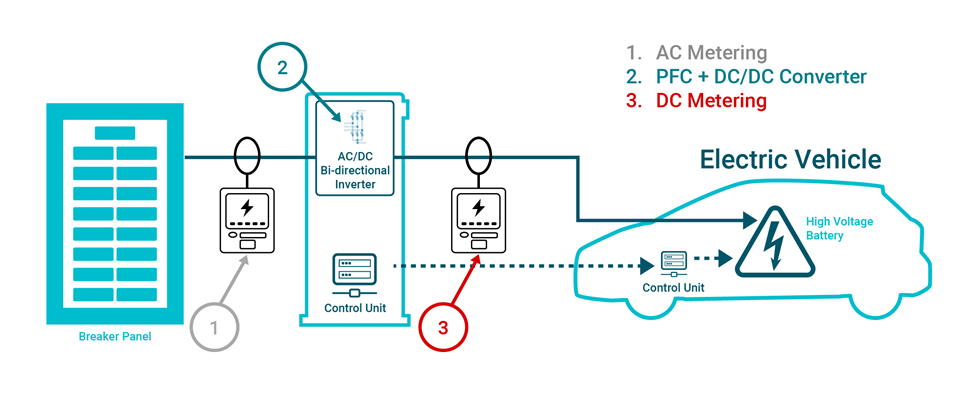

AC and DC chargers require metering to ensure the efficient use of energy and to monitor the power used to charge the vehicle. Metering in EV charging falls into three categories:

- AC metering. AC metering measures the energy coming into and out of the grid. There is a growing trend to integrate traditional metering units into AC chargers to enable direct connections to the grid.

- DC power module current sensing. While metering is often separate from power modules, there may be additional high-accuracy current monitoring needs. When used between the power modules of a DC charger, isolated amplifiers monitor how the modules are performing.

- DC metering. DC chargers can have several types of architectures because their stackable power modules scale the power rating for the charging unit up or down. There is sometimes a final metering point on the output of the DC charger (known as DC metering) to measure the voltages going into the vehicle, ensuring that consumers don’t pay for power dissipation between the DC charger and the vehicle charging socket, as shown in Figure 1.

Figure 1 Metering and current sensing inside AC/DC chargers

Figure 1 Metering and current sensing inside AC/DC chargersSensors in metering

Designers use a variety of sensors to conduct metering in AC and DC chargers: current transformers and shunt resistors are the most popular. While there are many different approaches to measuring power for energy calculations, discrete implementations give designers more flexibility and control over the metrology. Discrete solutions pair a precision analog-to-digital converter (ADC) with an external microcontroller to measure current and voltage from three phases (known as a polyphase metering architecture) off of a current transformer or shunt sensor. The ADC must be highly accurate in order to meet strict standards like American National Standards Institute (ANSI) C12 Class 0.5 or Class 0.2 meters. A high signal-to-noise ratio, low noise and a low gain error are also factors when determining whether a particular ADC is suitable for a metering application.

If you decide to use a current transformer as the sensor, the meter will require a high-accuracy multichannel precision ADC. The ADS131M08 24-bit ADC with integrated phase delay can help you exceed ANSI C12 metering standards. The ADS131B04-Q1 is a good fit for DC EV chargers with tighter offset error and drift specifications. For either ADC in this design, you may require using shielding to protect the meter from magnetic tampering. This is crucial to ensure the meter is accurately sensing the energy being used by the consumer.

A shunt sensor metering architecture has the same accuracy needs as a current transformer, but requires phase-to-phase and data isolation. Shunt sensors are inherently anti-magnetic, which removes the need for shielding and enables designs with a lower cost and a smaller form factor. The AMC131M03 24-bit isolated ADC has integrated data and power isolation, and radiated emissions performance that surpasses Comité International Spécial des Perturbations Radioélectriques 11 and 25 standards. This ADC provides high accuracy measurements through its signal-to-noise ratio and low gain error, while maintaining 7,070-VPEAK reinforced isolation with 5,000-VRMS isolation for 1 minute.

Table 1 lists precision ADC recommendations for different metering architectures.

| Sensor | AC metering | DC metering |

|---|---|---|

| Current transformer | ADS131M08 | ADS131B04-Q1 or ADS131M08 |

| Shunt | AMC131M03 | |

Conclusion

As requirements for AC and DC chargers increase, having a highly accurate metering solution become even more important. Precision ADCs enable accurate energy calculations and provide the flexibility required for you to build infrastructures for environmentally sustainable transportation.