TIDUEJ6A January 2019 – July 2022

- Description

- Resources

- Features

- Applications

- 5

- 1System Description

- 2System Overview

- 3Hardware, Software, Testing Requirements, and Test Results

- 4Design and Documentation Support

- 5About the Authors

- 6Revision History

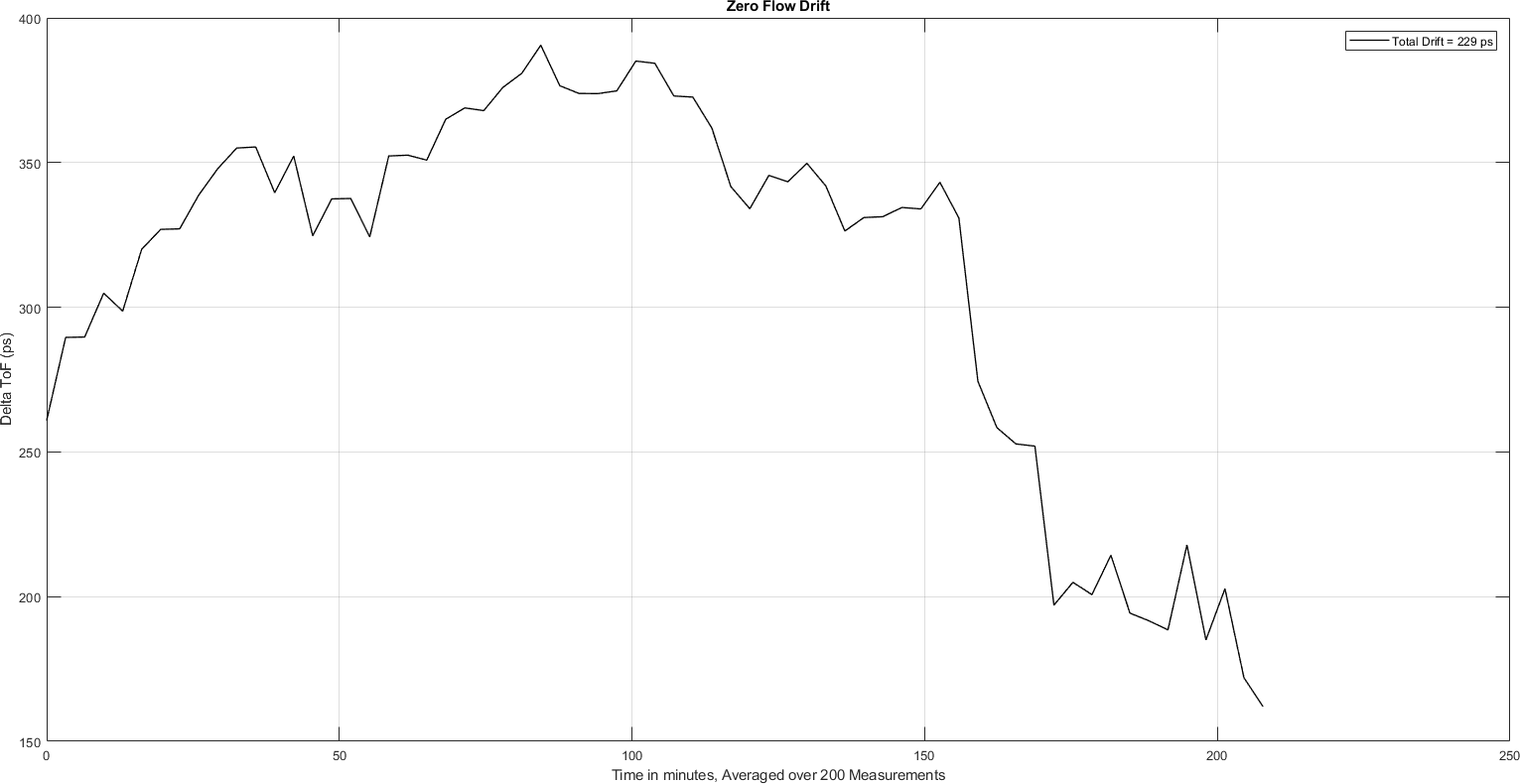

3.2.2.2 Zero-Flow Drift

Zero-flow drift (ZFD) is a measure used to express the expected drift of the DToF at zero-flow across temperature. This measure directly impacts the minimal detectable flow of the meter. Five transducer pairs of five different transducers from four manufacturers were tested for ZFD performance. Two separate ZFD tests were conducted with variable temperature at zero flow. A meter and device in-oven test varies the temperature of the gas meter and electronics over a –35°C to 65°C range. The device in-oven test varies the temperature of the electronics over –35°C to 65°C, while the meter is placed at room temperature. The oven profile used to calculate ZFD is shown in Figure 4-17, together with the expected change in absToF. As observed, the absToF is expected to vary over the temperature range.

ZFD is calculated by obtaining the range of the differential ToF averaged over 200 samples. The MSP430 Ultrasonic Design Center GUI can be used to capture the differential ToF, while tools like MATLAB or Excel can be used to calculate the average over 200 samples and the total drift.

Figure 4-16 shows the resulting differential ToF across temperatures, averaged over 200 samples.

Figure 4-16 Zero Flow Drift of DToF With EVM430-FR6043 in Oven

Figure 4-16 Zero Flow Drift of DToF With EVM430-FR6043 in Oven