SBOA540 March 2022 OPA210

1 Application Brief

Medical equipment designers and manufacturers for ultrasound scanners, MRI systems (magnetic resonance imaging), and X-ray machines rely on state-of-the-art active components to maintain signal integrity and provide medical personnel with high-resolution images for quick diagnosis.

With the evolution and the need for portability comes the challenge of smaller size and low power consumption while maintaining an acceptable noise floor. In ultrasounds, high-voltage precision bipolar op amps have been a natural choice. However, the large geometry of the input transistors can compromise the die size resulting in larger packages. With newer process technology and innovative design using super beta transistors like in the OPA2210 offered in WSON, system designers can now benefit from a very low noise floor without sacrificing the small size. Furthermore, the super beta input topology helps reduce the current noise density quite substantially when compared with traditional bipolar design.

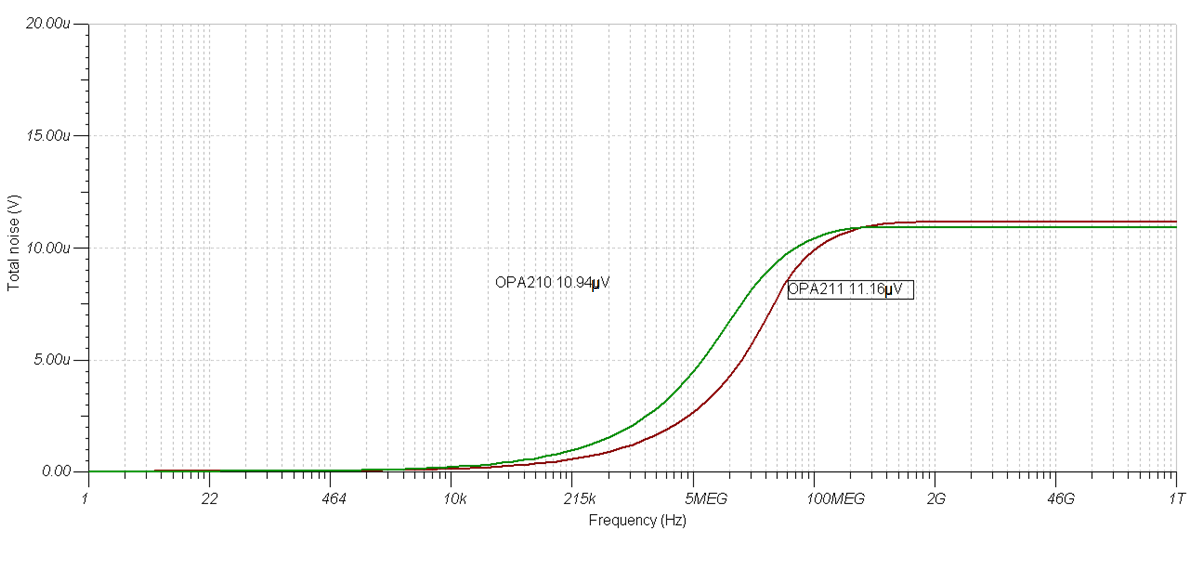

Figure 1-1 shows the total noise of the OPA210 and OPA211 used in a portion of the TGC (time gain compensation) drive circuit for ultrasound. Figure 1-2 and Figure 1-3 shows the circuits for the OPA210 and OPA211, respectively.

Figure 1-1 Total Noise of OPA210 and

OPA211 in TGC Drive Circuit for Ultrasound

Figure 1-1 Total Noise of OPA210 and

OPA211 in TGC Drive Circuit for UltrasoundWith the optimization for noise comes the challenge of maintaining adequate efficiency. Power consumption, heat dissipation, and package miniaturization are critical in portable medical apparatuses. And while low-noise precision amplifiers tend to consume more power (inverse proportionality rule between current and voltage noise), one exception is the OPA210 which not only has better total noise performance thanks to its super beta inputs but also provides 40% of power savings when compared to the popular ultra-noise OPA211. In addition, the closely matched input transistors of the super beta topology offer a lower input offset voltage and offset drift.

Modern medical equipment such as smart ultrasound probes require precision measurements and high efficiency in the front-end RX and TX signal chain. The OPA2205 is built on Texas Instruments' award-winning process technology. The combination of TI’s proprietary e-trim™ operational amplifier with super beta makes the OPA2205 a natural choice for low noise, high-efficiency circuits.

Other imaging equipment such as CT and

PET scanners require real-time image processing using higher resolution

analog-to-digital converters (precision ADCs). To maintain linearity and signal

integrity, a low-noise precision amplifier such as the OPA392 provides

a very low broadband noise of

4 nV/√Hz, which helps

reduce the overall system error.

The selection criteria for precision amplifiers should be based on process technology which enables higher efficiency without sacrificing noise and size. In general, bipolar op amps are known for better noise-to-power ratios compared to their CMOS or JFET counterparts.

For a wider selection of precision

amplifiers, visit TI's precision op amps online.

References

- Texas Instruments, Time Gain Control for Ultrasound Applications application report

- Texas Instruments, How to improve efficiency and precision with bipolar op amps

| Device | Supply Voltage (V) | Maximum Offset Voltage (mV) | Bandwidth (MHz) | Voltage Noise at 1 kHz (nV/) | Quiescent Current (mA) |

|---|---|---|---|---|---|

| OPA210 | 4.5–36 | 0.035 | 18 | 2.2 | 2.2 |

| OPA211 | 4.5–36 | 0.5 | 45 | 1.1 | 3.6 |

| OPA2205 | 4.5–36 | 0.015 | 3.6 | 7.2 | 0.22 |

| OPA392 | 1.7–5.5 | 0.01 | 13 | 6.5 | 1.2 |