SLVSA11G October 2009 – November 2015 DRV8828

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- PWP|28

Thermal pad, mechanical data (Package|Pins)

- PWP|28

Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The DRV8828 is used in brushed motor or stepper motor control. The onboard current regulation allows for limiting the motor current through simple pin configurations.

8.2 Typical Application

Figure 7. Motor Control Circuitry

Figure 7. Motor Control Circuitry

8.2.1 Design Requirements

For this design example, use the parameters listed in Table 3

Table 3. Design Parameters

| PARAMETER | REFERENCE | VALUE |

|---|---|---|

| Supply Voltage | VM | 24 V |

| Motor Winding Resistance | RM | 3.9 Ohm |

| Motor Winding Inductance | LM | 2.9 mH |

| Target Chopping Current | ITRIP | 1.5 A |

| Sense Resistor | RSENSE | 200 mΩ |

| VREF Voltage | VREF | 1.5 V |

8.2.2 Detailed Design Procedure

8.2.2.1 Current Regulation

The maximum current (ITRIP) is set by the Ix pins, the VREF analog voltage, and the sense resistor value (RSENSE). When starting a brushed DC motor, a large inrush current may occur because there is no back-EMF and high detent torque. Current regulation will act to limit this inrush current and prevent high current on start-up.

Example - If the desired chopping current is 1.5 A:

- Set RSENSE = 200 mΩ

- VREF would have to be 1.5 V

- Create a resistor divider network from V3P3OUT (3.3 V) to set VREF = 1.5 V

- Set R2 = 10 kΩ and set R1 = 12 kΩ

8.2.2.2 Sense Resistor

For optimal performance, it is important for the sense resistor to be:

- Surface-mount

- Low inductance

- Rated for high enough power

- Placed closely to the motor driver

The power dissipated by the sense resistor equals Irms² x R. For example, if the RMS motor current is 1.5 A and a 200 mΩ sense resistor is used, the resistor will dissipate 1.5 A² × 0.2 Ω = 0.3 W. The power quickly increases with greater current levels.

Resistors typically have a rated power within some ambient temperature range, along with a de-rated power curve for high ambient temperatures. When a PCB is shared with other components generating heat, margin should be added. It is always best to measure the actual sense resistor temperature in a final system, along with the power MOSFETs, as those are often the hottest components.

Because power resistors are larger and more expensive than standard resistors, it is common practice to use multiple standard resistors in parallel, between the sense node and ground. This distributes the current and heat dissipation.

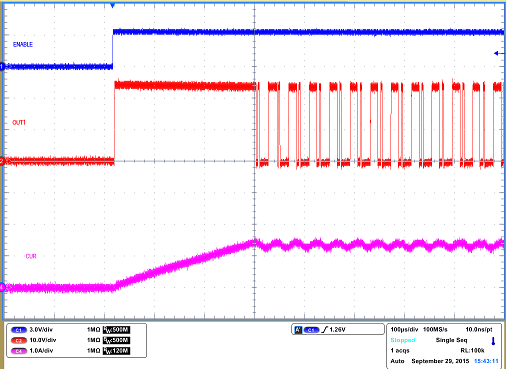

8.2.3 Application Curves

Figure 8. DRV8828 Current Limiting

Figure 8. DRV8828 Current Limiting

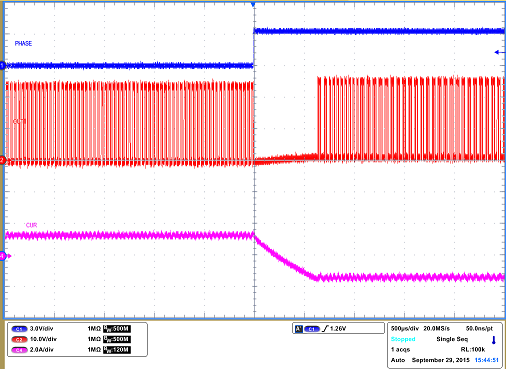

Figure 9. DRV8828 Direction Change

Figure 9. DRV8828 Direction Change