SNVSAH3E February 2018 – July 2020 LMR23625

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Fixed-Frequency Peak-Current-Mode Control

- 7.3.2 Adjustable Output Voltage

- 7.3.3 Enable/Sync

- 7.3.4 VCC, UVLO

- 7.3.5 Minimum ON-time, Minimum OFF-time and Frequency Foldback at Drop-out Conditions

- 7.3.6 Internal Compensation and CFF

- 7.3.7 Bootstrap Voltage (BOOT)

- 7.3.8 Overcurrent and Short-Circuit Protection

- 7.3.9 Thermal Shutdown

- 7.4 Device Functional Modes

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Applications

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Custom Design With WEBENCH® Tools

- 8.2.2.2 Output Voltage Setpoint

- 8.2.2.3 Switching Frequency

- 8.2.2.4 Inductor Selection

- 8.2.2.5 Output Capacitor Selection

- 8.2.2.6 Feed-forward Capacitor

- 8.2.2.7 Input Capacitor Selection

- 8.2.2.8 Bootstrap Capacitor Selection

- 8.2.2.9 VCC Capacitor Selection

- 8.2.2.10 Undervoltage Lockout Set-Point

- 8.2.3 Application Curves

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DDA|8

- DRR|12

Thermal pad, mechanical data (Package|Pins)

Orderable Information

7.3.3 Enable/Sync

The voltage on the EN/SYNC pin controls the ON or OFF operation of LMR23625. A voltage less than 1 V (typical) shuts down the device while a voltage higher than 1.6 V (typical) is required to start the regulator. The EN/SYNC pin is an input and cannot be left open or floating. The simplest way to enable the operation of the LMR23625 is to connect the EN to VIN. This allows self-start-up of the LMR23625 when VIN is within the operation range.

Many applications will benefit from the employment of an enable divider RENT and RENB (Figure 7-3) to establish a precision system UVLO level for the converter. System UVLO can be used for supplies operating from utility power as well as battery power. It can be used for sequencing, ensuring reliable operation, or supply protection, such as a battery discharge level. An external logic signal can also be used to drive EN input for system sequencing and protection.

Figure 7-3 System UVLO by Enable Divider

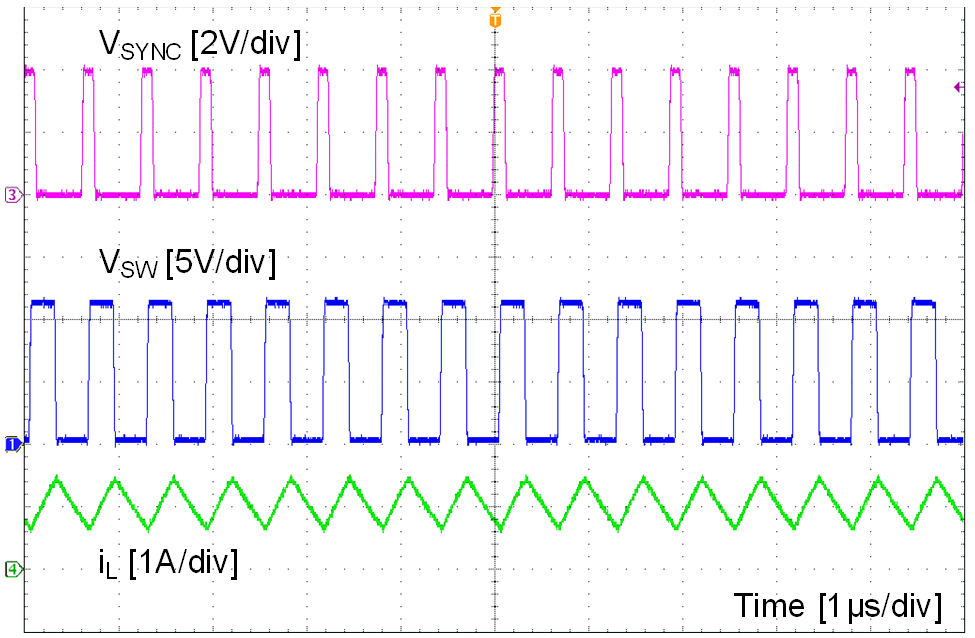

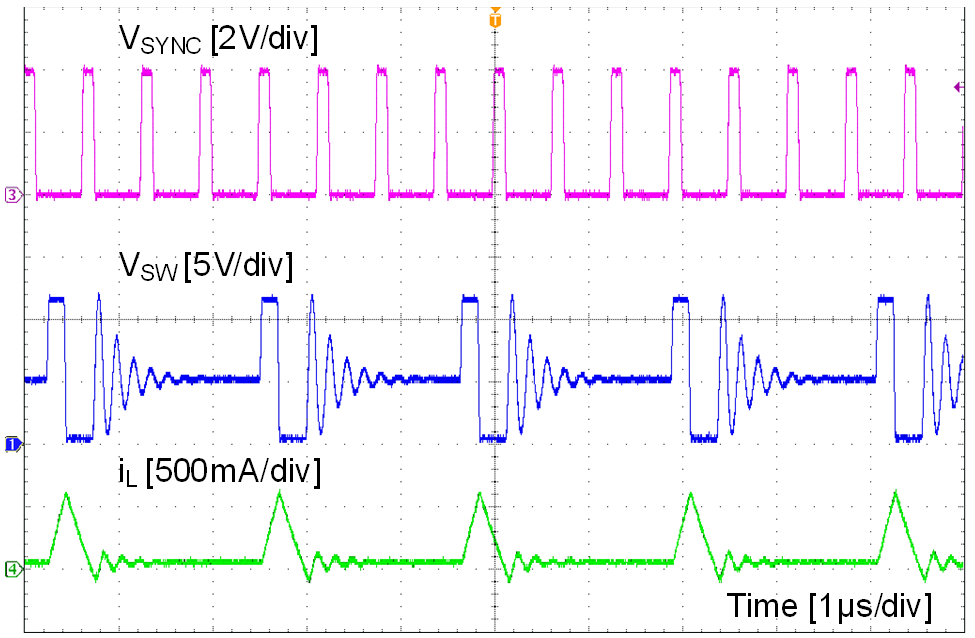

Figure 7-3 System UVLO by Enable DividerThe EN pin also can be used to synchronize the internal oscillator to an external clock. The internal oscillator can be synchronized by AC coupling a positive edge into the EN pin. The AC coupled peak-to-peak voltage at the EN pin must exceed the SYNC amplitude threshold of 2.8 V (typical) to trip the internal synchronization pulse detector, and the minimum SYNC clock ON and OFF time must be longer than 100ns (typical). A 3.3-V or higher amplitude pulse signal coupled through a 1-nF capacitor CSYNC is a good starting point. Keeping RENT // RENB (RENT parallel with RENB) in the 100-kΩ range is a good choice. RENT is required for this synchronization circuit, but RENB can be left unmounted if system UVLO is not needed. LMR23625 switching action can be synchronized to an external clock from 200 kHz to 2.2 MHz. Figure 7-5 and Figure 7-6 show the device synchronized to an external system clock.

Figure 7-4 Synchronize to External

Clock

Figure 7-4 Synchronize to External

Clock Figure 7-5 Synchronizing in PWM Mode

Figure 7-5 Synchronizing in PWM Mode Figure 7-6 Synchronizing in PFM Mode

Figure 7-6 Synchronizing in PFM Mode