SLVSDD7B August 2016 – March 2022 UCD9090A

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4

Device Functional Modes

- 7.4.1 Power Supply Sequencing

- 7.4.2 Pin-Selected Rail States

- 7.4.3 Monitoring

- 7.4.4 Fault Responses and Alert Processing

- 7.4.5 Shut Down All Rails and Sequence On (Resequence)

- 7.4.6 GPIOs

- 7.4.7 GPO Control

- 7.4.8 GPO Dependencies

- 7.4.9 GPI Special Functions

- 7.4.10 Power Supply Enables

- 7.4.11 Cascading Multiple Devices

- 7.4.12 PWM Outputs

- 7.4.13 Programmable Multiphase PWMs

- 7.4.14 Margining

- 7.4.15 Run Time Clock

- 7.4.16 System Reset Signal

- 7.4.17 Watch Dog Timer

- 7.4.18 Data and Error Logging to Flash Memory

- 7.4.19 Brownout Function

- 7.4.20 PMBus Address Selection

- 7.4.21 Device Reset

- 7.4.22 JTAG Interface

- 7.4.23 Internal Fault Management and Memory Error Correction (ECC)

- 7.5 Programming

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- RGZ|48

Thermal pad, mechanical data (Package|Pins)

- RGZ|48

Orderable Information

7.4.8 GPO Dependencies

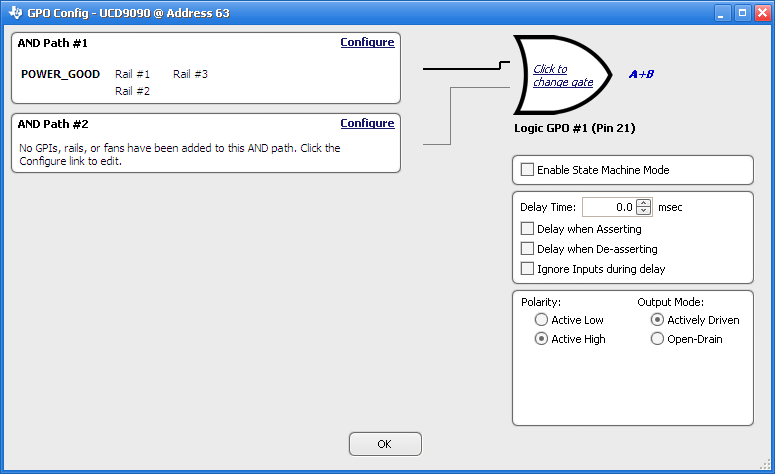

GPIOs can be configured as outputs that are based on Boolean combinations of up to two ANDs all ORed together (Figure 7-13). Inputs to the logic blocks can include the first 8 defined GPOs, GPIs and rail-status flags. One rail status type is selectable as an input for each AND gate in a Boolean block. For a selected rail status, the status flags of all active rails can be included as inputs to the AND gate. _LATCH rail-status types stay asserted until cleared by a MFR PMBus command or by a specially configured GPI pin. The different rail-status types are shown in Table 7-5. See the UCD90xxx Sequencer and System Health Controller PMBus Command Reference for complete definitions of rail-status types. The GPO response can be configured to have a delayed assertion or deassertion. The first 8 GPOs can be chosen as Rail Sequence on/off Dependency. The logic state of the GPO instead of actual pin output is used as dependency condition.

Figure 7-13 Boolean Logic Combinations

Figure 7-13 Boolean Logic Combinations Figure 7-14 Fusion Boolean Logic Builder

Figure 7-14 Fusion Boolean Logic Builder| Rail-Status Types | ||

|---|---|---|

| POWER_GOOD | IOUT_UC_FAULT | TOFF_MAX_WARN_LATCH |

| MARGIN_EN | TEMP_OT_FAULT | SEQ_ON_TIMEOUT_LATCH |

| MRG_LOW_nHIGH | TEMP_OT_WARN | SEQ_OFF_TIMEOUT_LATCH |

| VOUT_OV_FAULT | SEQ_ON_TIMEOUT | SYSTEM_WATCHDOG_TIMEOUT_LATCH |

| VOUT_OV_WARN | SEQ_OFF_TIMEOUT | IOUT_OC_FAULT_LATCH |

| VOUT_UV_WARN | SYSTEM_WATCHDOG_TIMEOUT | IOUT_OC_WARN_LATCH |

| VOUT_UV_FAULT | VOUT_OV_FAULT_LATCH | IOUT_UC_FAULT_LATCH |

| TON_MAX_FAULT | VOUT_OV_WARN_LATCH | TEMP_OT_FAULT_LATCH |

| TOFF_MAX_WARN | VOUT_UV_WARN_LATCH | TEMP_OT_WARN_LATCH |

| IOUT_OC_FAULT | VOUT_UV_FAULT_LATCH | |

| IOUT_OC_WARN | TON_MAX_FAULT_LATCH | |

When GPO is set to POWER_GOOD, this POWER_GOOD state is based on the actual voltage measurement on the monitor pins assigned to those rails. For a rail that does not have a monitor pin, or have a monitor pin but without voltage monitoring, its POWER_GOOD state is used by sequencing purpose only, and is not be used by the GPO logic evaluation.