JAJSK09B November 2014 – September 2020 CC3100MOD

PRODUCTION DATA

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 機能ブロック図

- 5 機能ブロック図

- 6 Revision History

- 7 Terminal Configuration and Functions

-

8 Specifications

- 8.1 Absolute Maximum Ratings

- 8.2 ESD Ratings

- 8.3 Power-On Hours (POH)

- 8.4 Recommended Operating Conditions

- 8.5 Power Consumption Summary

- 8.6 TX Power and IBAT versus TX Power Level Settings

- 8.7 Brownout and Blackout Conditions

- 8.8 Electrical Characteristics (3.3 V, 25°C)

- 8.9 WLAN RF Characteristics

- 8.10 Reset Requirement

- 8.11 Thermal Resistance Characteristics for MOB Package

- 8.12 Timing and Switching Characteristics

- 8.13 Host UART

- 9 Detailed Description

- 10Applications, Implementation, and Layout

- 11Environmental Requirements and Specifications

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

パッケージ・オプション

デバイスごとのパッケージ図は、PDF版データシートをご参照ください。

メカニカル・データ(パッケージ|ピン)

- MOB|63

サーマルパッド・メカニカル・データ

発注情報

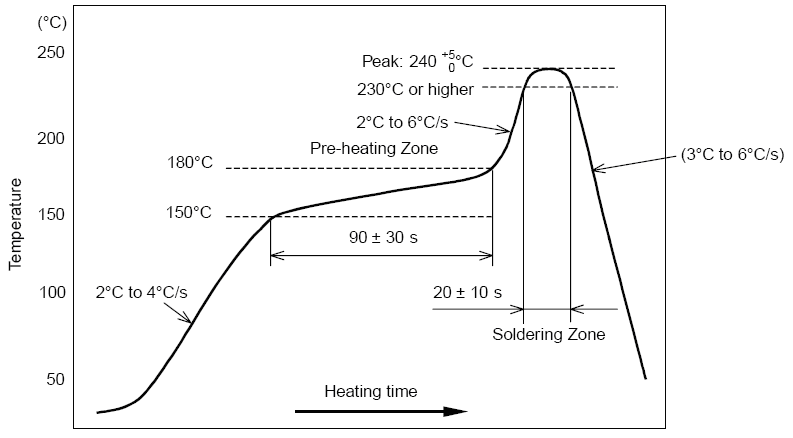

11.5 Soldering and Reflow Condition

- Heating method: Conventional convection or IR convection

- Temperature measurement: Thermocouple d = 0.1 mm to 0.2 mm CA (K) or CC (T) at soldering portion or equivalent method

- Solder paste composition: Sn/3.0 Ag/0.5 Cu

- Allowable reflow soldering times: 2 times based on the reflow soldering profile

(see Figure 11-1) - Temperature profile: Reflow soldering will be done according to the temperature profile (see

Figure 11-1) - Peak temp: 245°C

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at Solder Joint)

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at Solder Joint)