SNOA961A February 2017 – February 2023 LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

- Inductive Touch System Design Guide for HMI Button Applications

- 1Mechanical Design

- 2Sensor Design

- 3Summary

- 4Revision History

2.4.7 Sensor Spacers

Maintaining a consistent separation (gap) between the sensor and the target is critical to ensure effective sensing. The system design feature which provides this is the spacer.

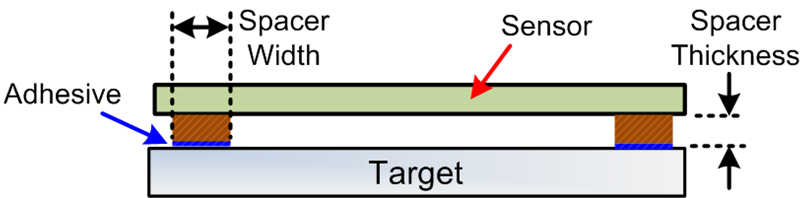

Figure 2-10 Spacer Thickness and Width

Figure 2-10 Spacer Thickness and WidthTypical spacer thicknesses range from 0.1 mm to 0.5 mm, depending on the sensor geometry and sensor electrical parameters. In general, thinner spacers provide better performance, provided the sensor electrical characteristics are within the LDC211x/LDC3114 boundary conditions. Setting the spacer thickness to less than 10% of the coil diameter (for a rectangular or elliptical shaped sensor, 10% of the shorter side) generally provides optimum performance.

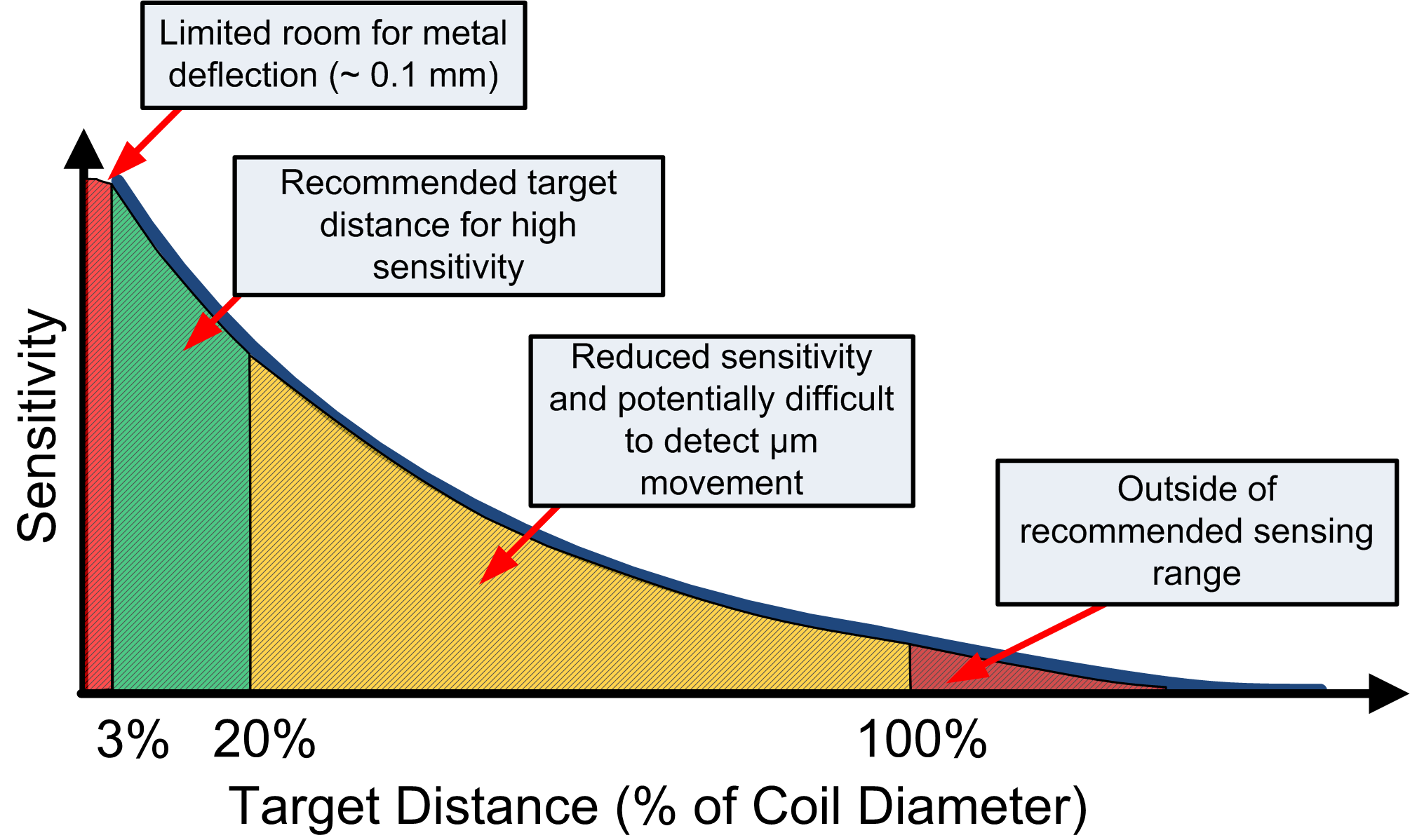

Figure 2-11 Measurement Sensitivity vs Target Distance

Figure 2-11 Measurement Sensitivity vs Target DistanceWider spacers may be needed when an adhesive is used to attach the sensor to the target surface, to provide a stronger attachment to the target.