SSZT352 january 2020

3D printing has the power to bring imagination to life by giving it a concrete shape. A student can translate his understanding of the physical world into 3D objects. A designer can transform ideas into real objects that they can touch and feel before going into production. A dentist can build a night guard right in the office without requiring the patient to return for another visit. The possibilities are endless.

The cost of a 3D printer ranges from less than $1,000 to more than $100,000. At lower price points, 3D printers are often referred to as desktop or personal 3D printers. One of the challenges for desktop 3D printers is print speed and print quality at affordable price points. In the desktop 3D printer segment, the popular technologies are fused filament fabrication (FFF) and stereolithography (SLA).

While inexpensive, FFF technology, also known as fused deposition modeling (FDM), has two fundamental limitations: speed and resolution due to point-by-point stitching of the filament material.

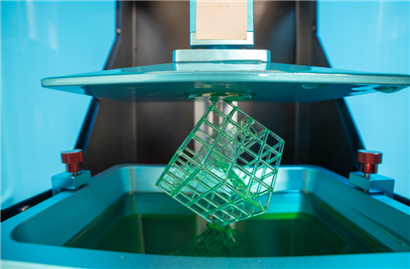

SLA, also known as photo polymerization, uses light and a material called photopolymers or resins. The photopolymers, upon exposure to ultraviolet (UV) or near-UV light, undergo a chemical reaction known as polymerization and turn into a solid object, as illustrated in Figure 1. Recent developments in material chemistry are enabling sub-$1,000 SLA printers, thus extending their reach into mainstream markets.

Figure 1 SLA 3D Printing

Figure 1 SLA 3D PrintingSLA technology can be implemented using one of two approaches:

- Laser-based (or point-based) systems: These systems use a high-power laser to cure the photopolymers “point by point.” The challenges of this approach include slow print speeds, calibration issues, total cost of ownership and the safety concerns of using high-power lasers.

- Layer-based systems: These systems use a projection light engine to cure an entire layer of the photopolymers at once, offering significantly higher print speeds. The projection light engine can be implemented with standard DLP technology or LCD technology.

LCD technology suffers from poor reliability, exposing liquid crystals to low-wavelength light causes the crystals to degrade over time. On the other hand, DLP technology is a microelectromechanical systems technology that modulates light using a digital micromirror device (DMD). DLP 3D printers have the fundamental advantages of high reliability, high accuracy and high speed.

Table 1 summarizes the key differences between the FFF and SLA technologies.

| Filament-based | Light-based (SLA) | |||

| FFF | Laser | LCD | DLP technology | |

| Speed | Medium | Medium | Medium | High |

| Resolution | Low | High | Medium | High |

| Size | Scalable | Scalable | Scalable | Scalable |

| Reliability | Medium | Medium | Low | High |

| Safety concerns | None | Some | None | None |

| Small form-factor light engine reference design for desktop 3D printers using DLP® Pico™ technology | |

Download the reference design here

Download the reference design here

|

With DMD micromirror arrays ranging in size from 0.2-inch diagonal up to 0.47 inches, DLP Pico chipsets are a good fit for desktop 3D printers. Here are four example application areas that can benefit greatly from the affordability and performance of DLP Pico products:

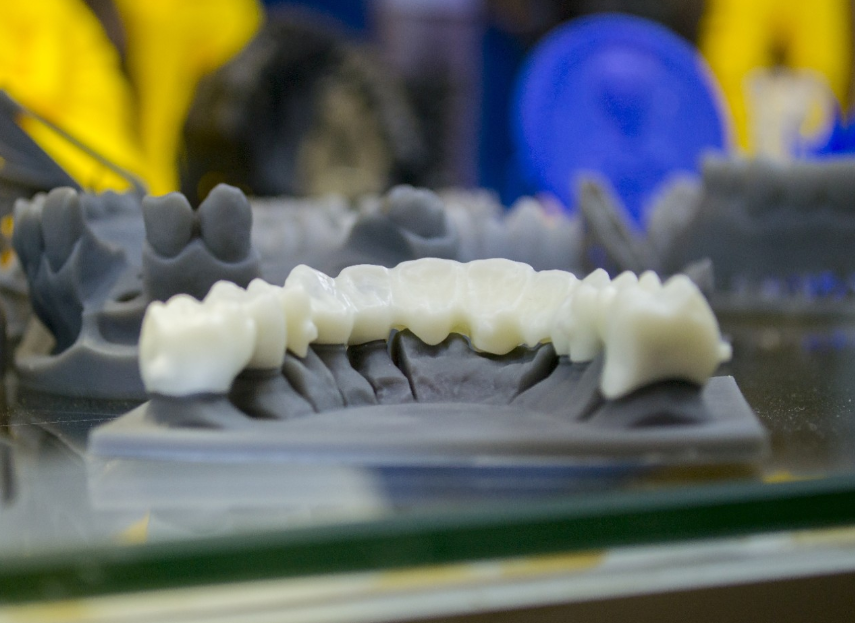

- Digital dentistry. A service typically performed by a dentist is the creation of various dental appliances, such as night guards, surgical guides and clear plastic braces. Digital dentistry, enabled by 3D dental scanners (both desktop and intra-oral) and 3D printers, makes this service more efficient by enabling dentists to fabricate appliances in-house, minimizing the time per patient and thus increasing productivity by bringing all of the advantages of DLP technology to the end-to-end process of capture-to-print. You can see an example of this application in Figure 2.

Figure 2 Digital dentistry with 3D

printing

Figure 2 Digital dentistry with 3D

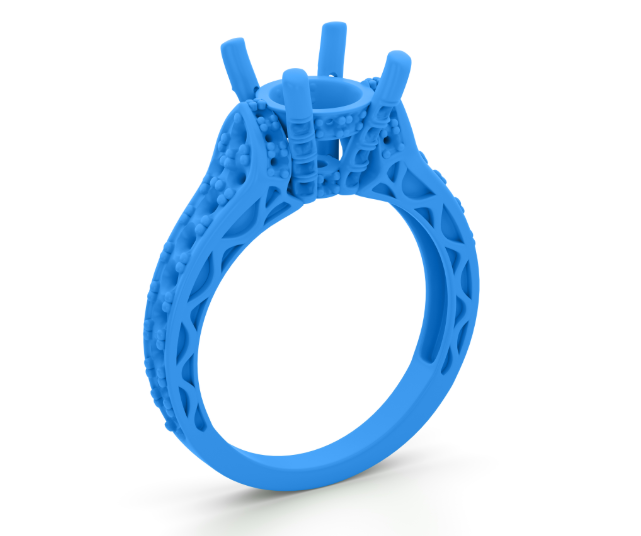

printing- Jewelry. The personalization of jewelry is an exciting market opportunity for 3D printing. You can see an example of a 3D printed ring in Figure 3. Resolution and smoothness are extremely important in jewelry design, which makes DLP Pico technology-based SLA printers an attractive technology for this application.

Figure 3 3D printing in jewelry

Figure 3 3D printing in jewelry- Engineering. Professional

designers and engineers use 3D printing to quickly prototype new ideas, allowing

them to evaluate of the look and feel of products before production. Examples of

prototypes can be seen in Figure 4.

Figure 4 3D Printing for

Prototyping

Figure 4 3D Printing for

Prototyping - Education. 3D printing is being incorporated into education at several levels. Printing and inspecting the prototypes of complex concepts such as 3D geometrical models, mechanical objects and human anatomy becomes a powerful learning process. Schools and libraries are making 3D printers available to students, enabling them to bring their ideas to life.

Figure 5 3D Printing in

Education

Figure 5 3D Printing in

EducationOptical modules for desktop 3D printers

Additional Resources:

- Learn more about 3D printing and 3D scanning.

- Read the technical article: Capture, Imagine and Create with DLP Pico Products.

- Check out the Getting started with TI DLP Pico technology page.