SSZT420 august 2019 BQ25155 , BQ25619

This post was originally authored by Manuel Diaz Corrada.

Thanks to advances in miniaturization, Bluetooth® communication and embedded processing, modern hearing aids have more features than ever, from streaming music to being able to adjust hearing amplification from an app on your smartphone.

These increased capabilities come at a price, however: modern features require more power. Increased power consumption is a challenge for engineers designing hearing aids, primarily because older versions use disposable zinc air batteries. These batteries typically last about two weeks. But when you add more features to hearing aids, such as giving them the ability to play music, the battery life could drop down to hours. Thus, engineers are using rechargeable lithium batteries in their next-generation hearing aid designs.

Rechargeable lithium batteries increase the power system complexity in a variety of ways, the most important being how to safely and accurately charge the battery. There are also extra design considerations when using two hearing aids. Because the left and right earpieces have no physical connection, it is not possible to charge both of them through a single cable simultaneously. So almost all new hearing aids are now equipped with a case that has both charging and storage functions.

This case is designed with specific sockets for each earpiece to ensure proper charging. The charging for the earpieces must be precise, since rechargeable hearing aids are typically 25 mAh-75 mAh and the charging case ranges from 300 mAh-70 0mAh. This translates to about 24 hours of usage for the earpieces and about 10 recharge cycles from the case, before the case itself needs to be re-charged.

With a charging case, hearing aid designers now have three different lithium batteries to consider: one for the case and two for the earpieces. The choice of battery chargers plays a significant role in the design.

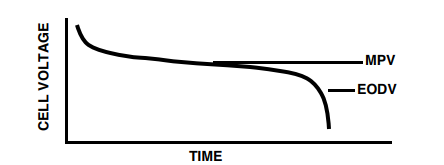

It is also critical to note that charging a battery from a battery (i.e. charging the earpiece battery from the charging case battery) is not as simple as charging from the wall, since the voltage difference between the two batteries will not be very large. There has to be internal circuitry to boost the voltage difference between the charging case and the earpieces to enable full charging. As the battery discharges, its voltage is slowly dropping. Looking at the discharge curve shown in Figure 1, at around 50% of battery capacity, the charging case voltage would be at around 3.6 V. But that means that without a boost, the charging case can only charge the earpieces up to 3.6 V, even when the energy stored in the case is sufficient to charge them fully.

Figure 1 A sample battery discharge

curve for a lithium-ion battery; the typical mean point voltage is 3.6 V and the

end-of-discharge voltage is 3 V (Source: “Characteristics of Rechargeable Batteries”)

Figure 1 A sample battery discharge

curve for a lithium-ion battery; the typical mean point voltage is 3.6 V and the

end-of-discharge voltage is 3 V (Source: “Characteristics of Rechargeable Batteries”)In such a scenario, most engineers would think to use a discreet boost. While a discreet boost does work, it typically increases solution size and inefficiencies by adding an additional boost and inductor component to the power architecture.

To overcome these challenges, consider on-the-go charging supported by quiescent currents. For example, TI’s BQ25619 battery charger and BQ25155 linear charger support charging without an external boost. In the hearing aid application, you could place the BQ25619 in the charging case and the BQ25155 within each earpiece.

Then, instead of always boosting the charging case output to 5 V, you would instead boost to the minimum voltage necessary to allow sufficient headroom between the charging case and earpiece batteries using the BQ25619’s boost functionality. This reduces the power loss of unnecessary boosting and also increases earpiece charging efficiency, since the voltage differences are reduced.

The BQ25155 is a good fit for the earpieces, since its 3.4-V input voltage minimum allows longer charging without the boost, and its 43-µA quiescent current increases battery run time. Meanwhile, the BQ25619’s 7-µA quiescent current in ship mode maximizes charging case shelf life. The BQ25619’s 20-mA charge termination current enables it to charge small-sized batteries with 7% more capacity.

The good news is that these benefits are not limited to hearing aids: all two-battery device systems, including earbuds and wearable patches, can benefit from these innovations. TI will continue to implement two-charger configuration in future designs with features like:

- Higher efficiency charging for both the earpieces and charging case while providing battery monitoring and protection, and reducing the total bill of materials with an integrated boost.

- Pin reduction for earpieces and charging cases by requiring only one line of communication.

With the BQ25619 and the BQ25155, you can improve the amount of charge cycles that are extractable from a charging case without increasing cost or solution size.

Additional resources

- Read the application report: Dynamic Power-Path Management and Dynamic Power Management

- Read the technical note: How to Design Tiny, Long-Lasting, and Safe Battery Products with Switching Chargers