SSZT590 november 2018 DRV5032

For a professional tradesperson, inoperable or malfunctioning tools halt job progress and can end up wasting time and money.

In recent years, battery-operated tools have replaced traditional compressed-air and mains-powered tools. High-performance, high-torque tools with long-lasting batteries have replaced older cordless tools that were previously inadequate for industrial usage. The freedom to work and move about safely on a job site without being tethered to a bulky air compressor with hoses or power cord comes as a relief to professional tradespeople who deal with these hazards daily.

But what about the reliability of handheld, battery-operated tools? Tools exposed to harsh environments full of oil, grease and dirt constitute a perfect recipe for gummed-up triggers or multi-position selector switches. This can cause electrical contact malfunctions and render tools useless.

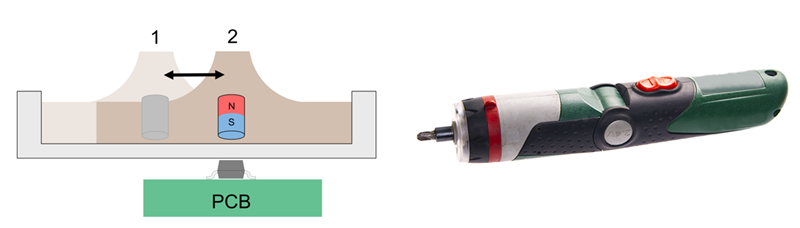

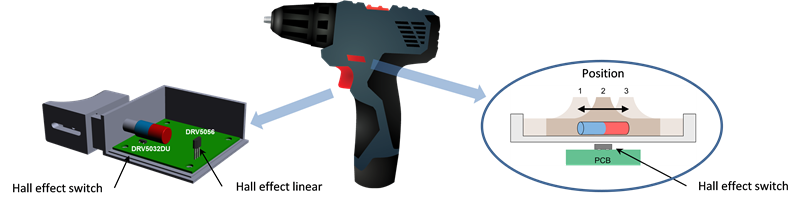

As a tool designer, Hall effect-based switches appear as a favorable solution against common contamination issues. Unlike mechanical switches, Hall effect-based switches provide contactless solutions for triggers and selectors. As shown in Figure 1 and Figure 2, by placing a magnet on the selector, a Hall effect sensor inside of the tool will detect the position based on the magnetic flux density it reads from the magnet. Magnetic fields travel through many media of contaminants and dirt, which help create highly reliable tools for construction sites and mechanic shops.

Also shown in Figure 2 is a trigger comprised of a Hall effect linear and switch, which is used to keep the system in a low-power state. Once the trigger is depressed the switch detects this movement and turns on the linear device allowing for highly accurate linear movement measurements which ultimately controls the speed of the power tool.

Figure 1 Speed Selector

Figure 1 Speed Selector Figure 2 Trigger and

Forward/neutral/reverse Selector

Figure 2 Trigger and

Forward/neutral/reverse Selector| Learn more about your Hall effect switch options | |

|

TI offers a family of small, low-power Hall effect switches. Explore possibilities with the DRV5032. |

Mechanical switches also wear out much sooner than Hall effect sensors due to the constant friction of moving parts. Being contactless, Hall effect sensors are highly reliable and immune to wear.

TI offers a variety of Hall effect sensors with different magnetic responses, voltage levels and power consumption. TI also offers magnetic calculators and other tools to help you select the appropriate combination of magnet material, size and shape, as well as how to choose a Hall effect sensor with a suitable magnetic sensitivity.

Additional Resources

- Learn more about TI’s magnetic Hall effect sensors.

- Check out our Hall effect videos.