SLVUCO1A May 2023 – April 2024 DRV8213 , DRV8214 , DRV8234

PRODUCTION DATA

3.5 DRV8213EVM

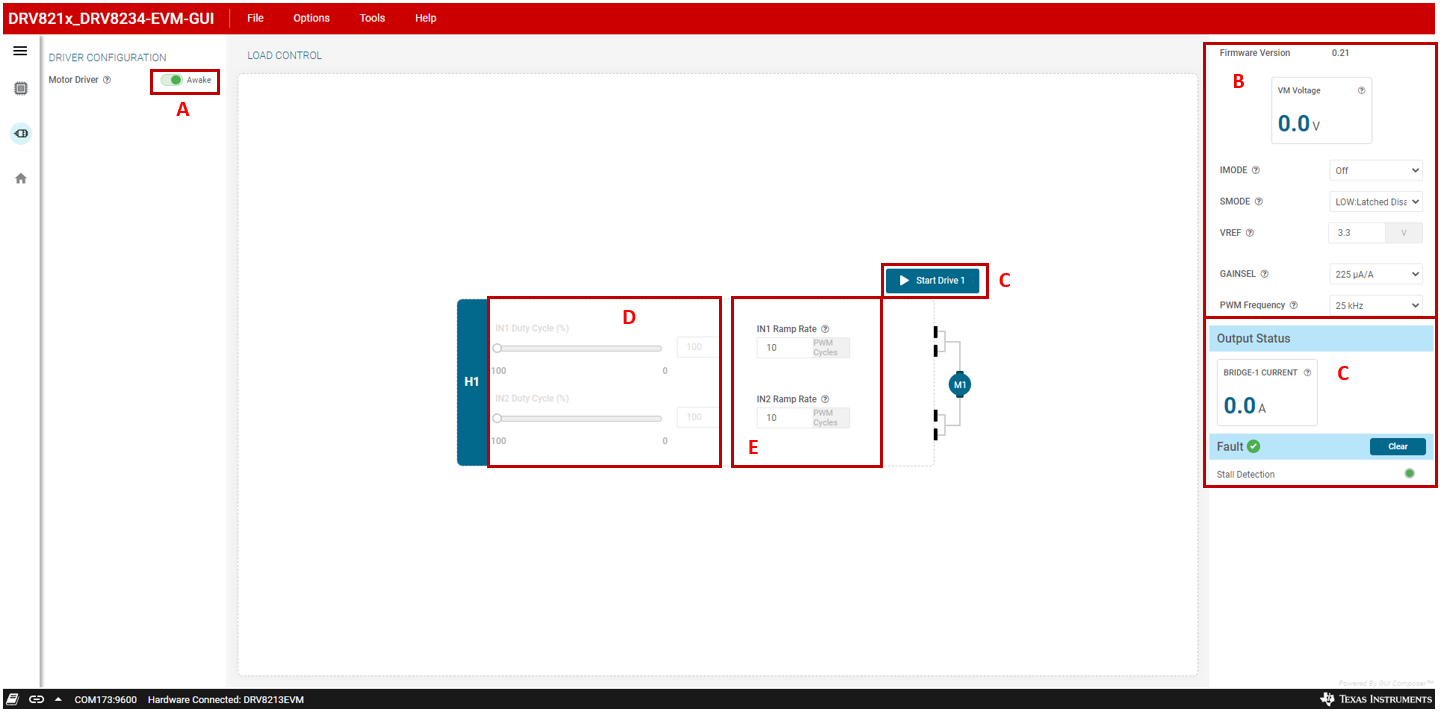

Figure 4-6 provides the overview of all the widgets and features of the DRV8213EVM GUI.

Figure 3-6 DRV8213 GUI Driver Control

Page

Figure 3-6 DRV8213 GUI Driver Control

PageTable 3-1 DRV8213EVM GUI

Overview

|

Component |

Description |

|---|---|

|

A |

Device enable. Set slider to GREEN position to enable the driver. |

|

B |

|

|

Col |

|

| D | IN1 and IN2 duty cycle control widget. Duty cycle ranges from 0-100 at the user selected PWM frequency. The duty cycle is adjustable by using the slider or writing to the input box. |

| E | IN1 and IN2 ramp rate. The PWM slowly ramps up or down the duty cycle to avoid sudden speed changes. The ramp rate is adjustable from 0-25 with 0=no ramp and 25=slowest ramp rate. |