SNLU291B March 2021 – August 2022 MCT8316Z

3 Quick Start Guide

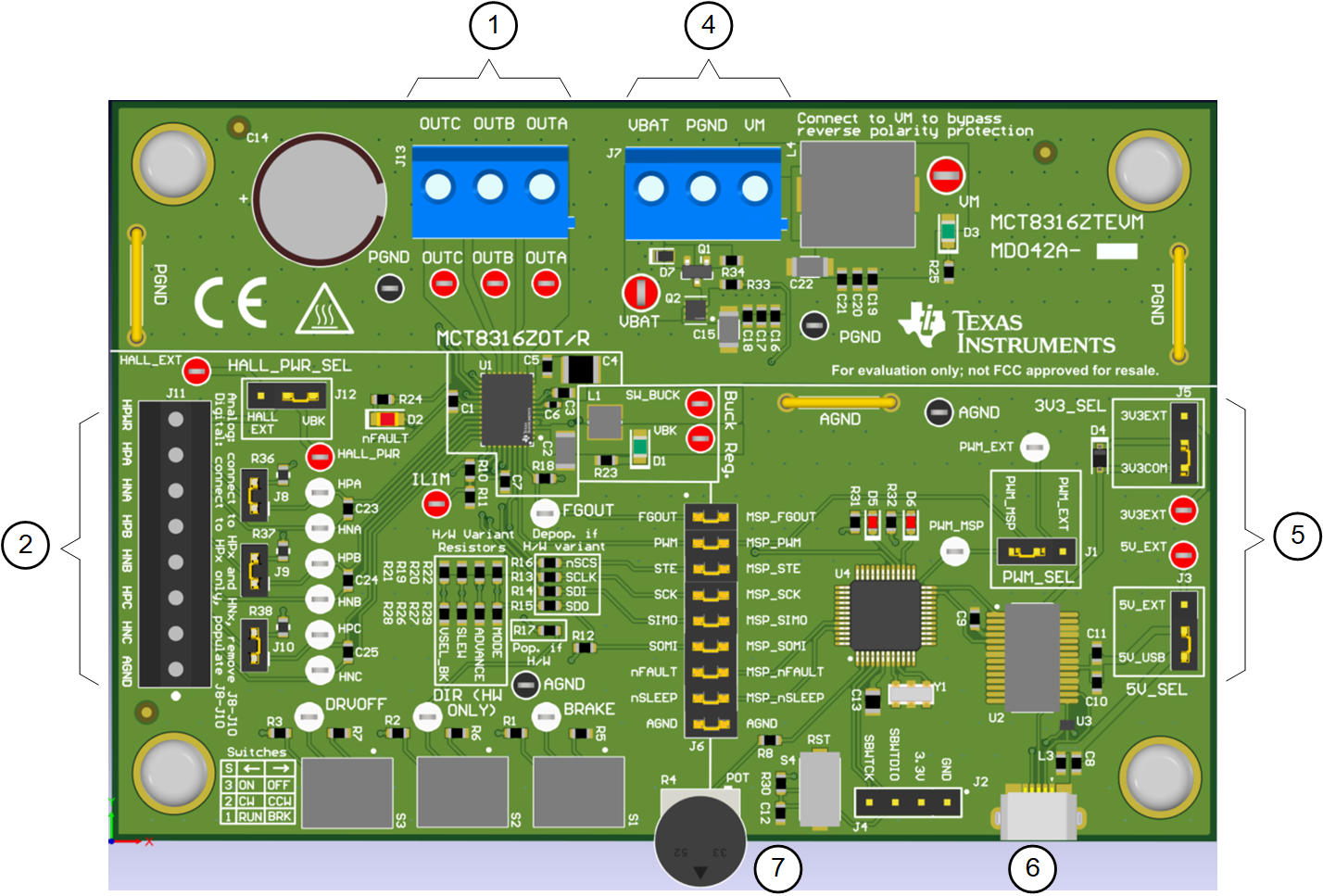

The MCT8316ZTEVM requires a power supply source, which has a recommended operating range from a 4.5 V to 35 V. To setup and power the EVM, use the following the sequence:

- Connect motor phases to A, B, and C on connector J13.

- Connect Hall sensors to J11 and select Hall power

supply as 3.3 V from buck or an external Hall supply on J12.

Ensure the MODE resistors are set correctly to use the

appropriate Hall sensor configuration as described in Section 4.6.

- If using digital Hall inputs, populate J8–J10 with shunt jumpers to enable pullups. Connect the single-ended inputs to only the HPx pins on connector J11. This is the default of the MCT8316ZTEVM.

- If using analog Hall inputs, remove J8-J10 and connect differential Hall inputs to HPx and HNx on connector J11.

- Ensure resistors are populated in H/W variant resistors for desired hardware settings.

- Do not turn on the power supply yet. Connect the

motor supply to VBAT or VM and PGND on connector J7.

- To enable reverse polarity protection and Pi filter, connect to VBAT. Note that when connecting to VBAT, VM will be VM – 0.7 V less, due to a diode drop in the reverse-polarity protection circuit.

- To disable reverse-polarity protection and the Pi filter, connect to VM.

- Select J3 to 5V_USB and J5 to 3V3COM to power MSP430 from USB power supply.

- Connect the micro-USB cable into the computer.

- Turn the potentiometer fully clockwise to set the motor to zero speed upon powerup.

- Turn on the motor power supply.

- Use the potentiometer to control the speed of the motor and the switches to disable the motor driver, change the direction, or apply a brake to the motor. Optionally, use the GUI (as shown in Section 6) to monitor real-time speed of the motor, put the MCT8316ZT into a low-power sleep mode, and read status of the LEDs.

Figure 3-1 Reference for

Quick Start Guide

Figure 3-1 Reference for

Quick Start Guide