SNLU291B March 2021 – August 2022 MCT8316Z

4.2 Connection Details

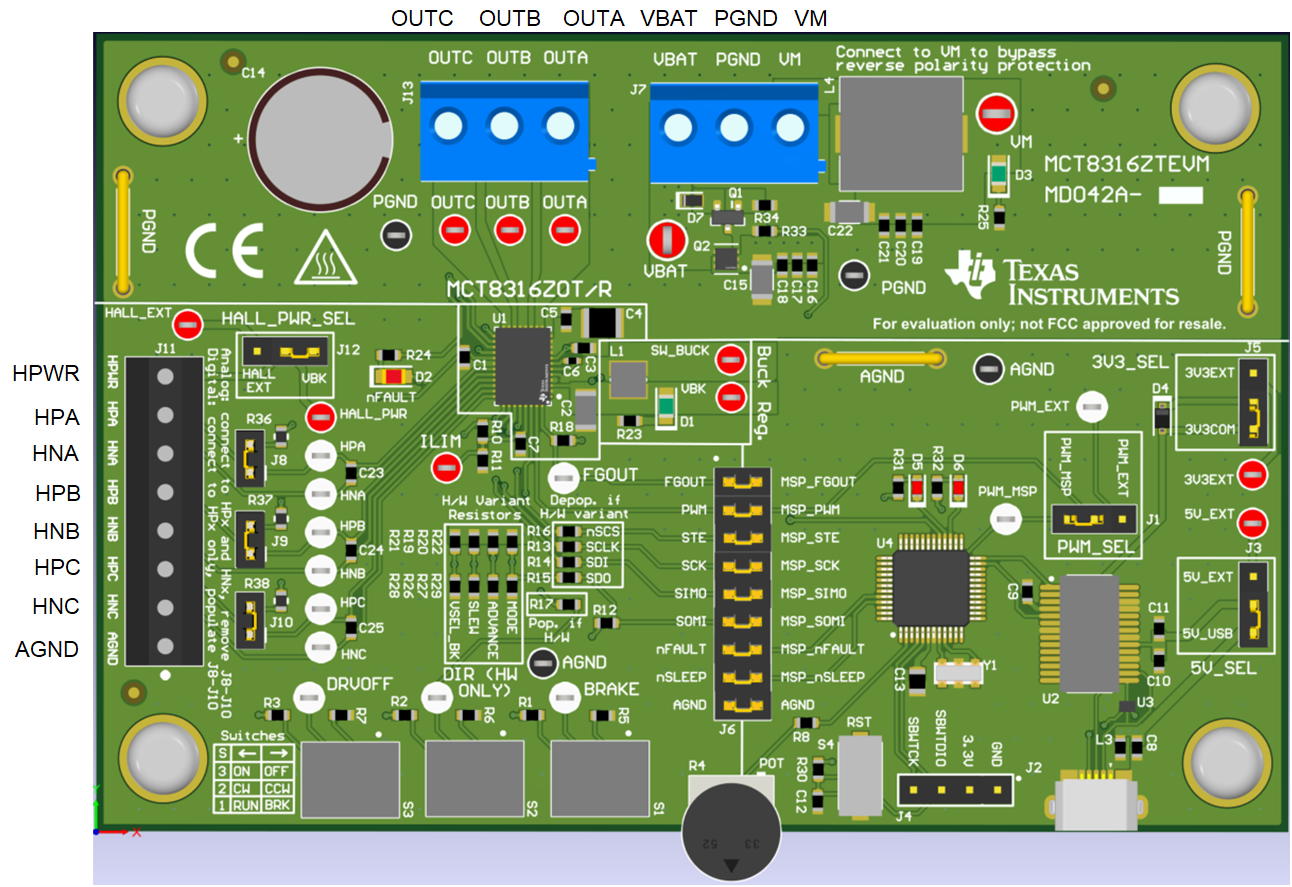

Figure 4-2 shows the connections made to the MCT8316ZTEVM to spin a 3-phase sensored brushless-DC motor.

A 4.5-V to 36-V power supply or battery is connected to the supply voltage (VBAT) or motor voltage (VM) and PGND terminals on connector J7. There is a reverse-polarity protection and Pi filter implemented on the VBAT and PGND terminals, resulting in a 0.7-V diode voltage supply drop to VM. To bypass the reverse-polarity protection and Pi filter, connect the power supply directly to the VM terminal or VM test point on the board and PGND.

The three phases of the BLDC motor connect directly to the A, B, and C terminals of the screw terminal connector J13 provided on the MCT8316ZTEVM.

Use connector J11 on the MCT8316ZTEVM to connect single-ended digital or analog differential Hall inputs. Use HALL_PWR for Hall power and AGND for Hall ground. If connecting analog inputs from a Hall element, connect to the HPx and HNx pins for each respective phase and remove jumpers J8-10. Otherwise, if using single-ended input from a Hall sensor, connect to only the HPx pins for each phase and populate jumpers R8–R10.

Figure 4-2 Connections from Motor to MCT8316ZTEVM

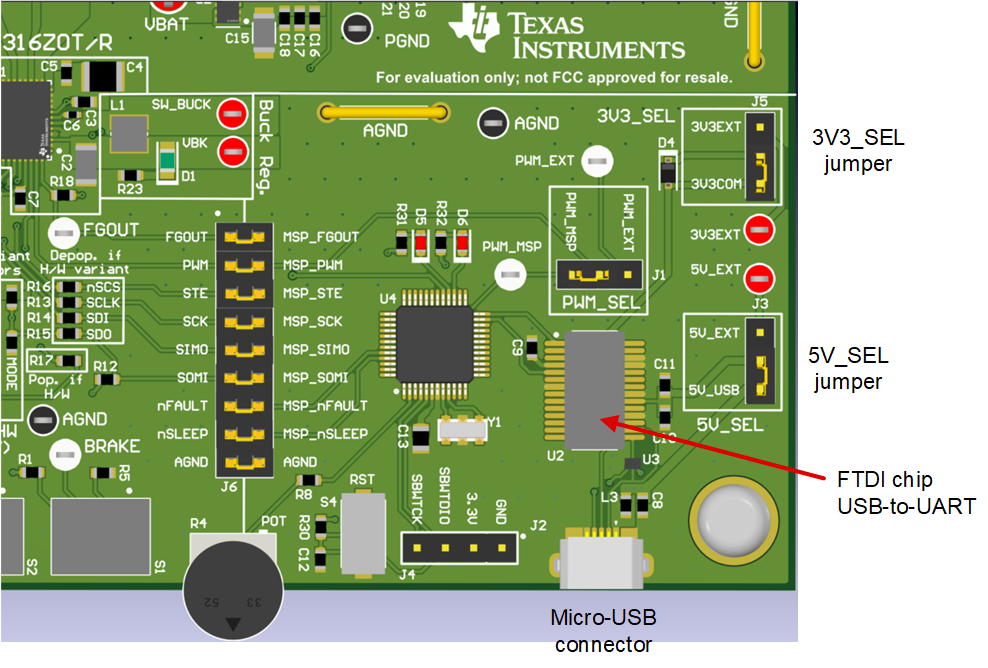

Figure 4-2 Connections from Motor to MCT8316ZTEVMFigure 4-3 shows where the micro-USB cable is plugged into the MCT8316ZTEVM to provide communication between evaluation module and GUI. The USB data and 5-V power from the USB is converted into UART data and 3.3-V power to power the MSP430FR2355 microcontroller. The 5 V from the USB power is limited to 500 mA by the PC and the 3.3 V from the FTDI chip is limit to 30 mA. If the user wishes to supply more current to these rails, they may use the 5V_SEL jumper J3 and 3V3_SEL jumper J5 to connect external power rails.

Figure 4-3 Micro-USB Connector and UART for MCT8316ZTEVM

Figure 4-3 Micro-USB Connector and UART for MCT8316ZTEVM