TIDUEP0 May 2020

- Description

- Resources

- Features

- Applications

- 1Design Images

- 2System Description

-

3System Overview

- 3.1 Block Diagram

- 3.2 Design Considerations

- 3.3

Highlighted Products

- 3.3.1 TPD4E05U06 4-Channel Ultra-Low-Capacitance IEC ESD Protection Diode

- 3.3.2 TPD2EUSB30 2-Channel ESD Solution for SuperSpeed USB 3.0 Interface

- 3.3.3 2.3.3 HD3SS3220 10Gbps USB 3.1 USB Type-C 2:1 MUX With DRP Controller

- 3.3.4 TPS54218 2.95V to 6V Input, 2A Synchronous Step-Down SWIFT™ Converter

- 3.3.5 TPS54318 2.95V to 6V Input, 3A Synchronous Step-Down SWIFT™ Converter

- 3.3.6 CSD19538Q3A 100V, N ch NexFET MOSFET™, single SON3x3, 49mOhm

- 3.3.7 LM3488 2.97V to 40V Wide Vin Low-Side N-Channel Controller for Switching Regulators

- 3.3.8 TPS61178 20-V Fully Integrated Sync Boost with Load Disconnect

- 3.3.9 LMZM23601 36-V, 1-A Step-Down DC-DC Power Module in 3.8-mm × 3-mm Package

- 3.3.10 TPS7A39 Dual, 150mA, Wide-Vin, Positive and Negative Low-Dropout (LDO) Voltage Regulator

- 3.3.11 TPS74201 Single-output 1.5-A LDO regulator, adjustable (0.8V to 3.3V), any or no cap, programmable soft start

- 3.3.12 LP5910 300-mA low-noise low-IQ low-dropout (LDO) linear regulator

- 3.3.13 LP5907 250-mA ultra-low-noise low-IQ low-dropout (LDO) linear

- 3.3.14 INA231 28V, 16-bit, i2c output current/voltage/power monitor w/alert in wcsp

- 3.4

System Design Theory

- 3.4.1 Input Section

- 3.4.2

Designing of SEPIC based High Voltage Supply

- 3.4.2.1 Basic Operation Principle of SEPIC Converter

- 3.4.2.2 Design of Dual SEPIC Supply using uncoupled inductors

- 3.4.2.3 Duty Cycle

- 3.4.2.4 Inductor Selection

- 3.4.2.5 Power MOSFET Selection

- 3.4.2.6 Output Diode Selection

- 3.4.2.7 Coupling Capacitor Selection

- 3.4.2.8 Output Capacitor Selection

- 3.4.2.9 Input Capacitor Selection

- 3.4.2.10 Programming the Output Voltage

- 3.4.3 Designing the Low Voltage Power Supply

- 3.4.4 Designing the TPS54218 through Webench Power Designer

- 3.4.5 ± 5V Transmit Supply Generation

- 3.4.6 System Clock Synchronization

- 3.4.7 Power and data output connector

- 3.4.8 System Current and Power Monitoring

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Layout Guidelines

- 6Design Files

- 7Software Files

- 8Related Documentation

- 9About the Author

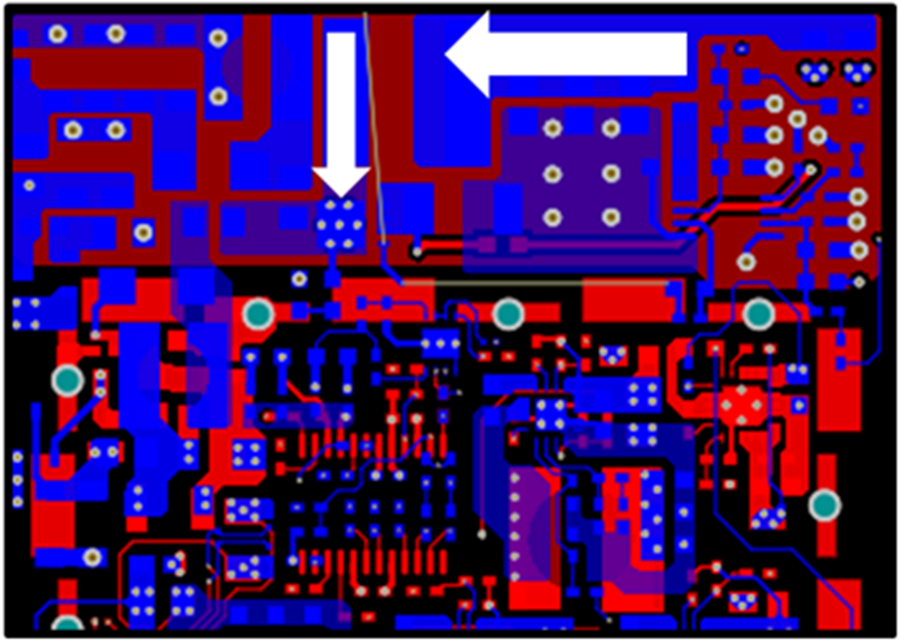

5.1 High-Voltage Supply Layout

Layout in SEPIC is very critical. While designing, the most important rule is to reduce the noise in the high current switching loop, which is shown in Figure 51. The current flows from the input supply to the primary inductor and through the MOSFET. To minimize induced EMF due to switching currents, it is desirable to keep parasitic inductance of this loop as low as possible. Components (primary inductors, input electrolytic capacitors, and FET) must be placed as close as possible to each other. In this layout, a single ground plane was used, and all the signals return onto this low impedance plane, as shown in Figure 52. In case the HV circuit is placed in proximity to the transducer, shielding might be necessary to minimize effects of radiated interference from HV section.