SLOS738E September 2012 – August 2015 AFE5809

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics

- 7.6 Digital Demodulator Electrical Characteristics

- 7.7 Digital Characteristics

- 7.8 Switching Characteristics

- 7.9 SPI Switching Characteristics

- 7.10 Output Interface Timing Requirements (14-bit)

- 7.11 Typical Characteristics

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6

Register Maps

- 8.6.1

ADC and VCA Register Description

- 8.6.1.1 ADC Register Map

- 8.6.1.2

AFE5809 ADC Register/Digital Processing Description

- 8.6.1.2.1 AVERAGING_ENABLE: Address: 2[11]

- 8.6.1.2.2 ADC_OUTPUT_FORMAT: Address: 4[3]

- 8.6.1.2.3 ADC Reference Mode: Address 1[13] and 3[15]

- 8.6.1.2.4 DIGITAL_GAIN_ENABLE: Address: 3[12]

- 8.6.1.2.5 DIGITAL_HPF_ENABLE

- 8.6.1.2.6 DIGITAL_HPF_FILTER_K_CHX

- 8.6.1.2.7 LOW_FREQUENCY_NOISE_SUPPRESSION: Address: 1[11]

- 8.6.1.2.8 LVDS_OUTPUT_RATE_2X: Address: 1[14]

- 8.6.1.2.9 CHANNEL_OFFSET_SUBSTRACTION_ENABLE: Address: 3[8]

- 8.6.1.2.10 SERIALIZED_DATA_RATE: Address: 3[14:13]

- 8.6.1.2.11 TEST_PATTERN_MODES: Address: 2[15:13]

- 8.6.1.2.12 SYNC_PATTERN: Address: 10[8]

- 8.6.1.3 VCA Register Map

- 8.6.1.4 VCA Register Description

- 8.6.2 Digital Demodulator Register Description

- 8.6.1

ADC and VCA Register Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2 Typical Application

- 9.3 System Example

- 9.4

Do's and Don'ts

- 9.4.1 Driving the Inputs (Analog or Digital) Beyond the Power-Supply Rails

- 9.4.2 Driving the Device Signal Input With an Excessively High Level Signal

- 9.4.3 Driving the VCNTL Signal With an Excessive Noise Source

- 9.4.4 Using a Clock Source With Excessive Jitter, an Excessively Long Input Clock Signal Trace, or Having Other Signals Coupled to the ADC or CW Clock Signal Trace

- 9.4.5 LVDS Routing Length Mismatch

- 9.4.6 Failure to Provide Adequate Heat Removal

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- ZCF|135

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

Figure 98 lists a typical application circuit diagram. The configuration for each block is discussed in the following sections. lists companion TI devices to complete the analog signal chain in a system.

Table 25. Application Companion Devices

| Part Number | Part Description | Functions |

|---|---|---|

| THS4130, SLOS318 | Fully Differential Input/Output Low Noise Amplifier With Shutdown | TGC Vcntl Opamp, CW summing amplifier and active filter |

| OPA1632, SBOS286 | Fully Differential I/O Audio Amplifier | TGC Vcntl amplifier, CW summing amplifier and active filter |

| OPA2211A, SBOS377 | 1.1nV/rtHz Noise, Low Power, Precision Operational Amplifier | CW summing amplifier and active filter |

| LME49990, SNOSB16 | Ultra-low Distortion, Ultra-low Noise Operational Amplifier | CW summing amplifier and active filter |

| LMH6629, SNOSB18 | Ultra-Low Noise, High-Speed Operational Amplifier with Shutdown | CW summing amplifier and active filter |

| ADS8413, SLAS490 | 16-bit, Unipolar Diff Input, 2MSPS Sampling rate, 4.75V to 5.25V ADC with LVDS Serial Interface | CW Audio ADC |

| ADS8881, SBAS547 | 18-Bit, 1-MSPS, Serial Interface, microPower, Truly-Differential Input, SAR ADC | CW Audio ADC |

| DAC7811, SBAS337 | 12-Bit, Serial Input, Multiplying Digital to Analog Converter | TGC Vcntl Digital to Analog Converter |

| LMK04803, SNAS489 | Low Noise Clock Jitter Cleaner With Dual Cascaded PLLs and Integrated 1.9 GHz VCO | Jitter cleaner and clock synthesizer |

| CDCM7005, SCAS793 | High Performance, Low Phase Noise, Low Skew Clock Synchronizer | Jitter cleaner and clock synthesizer |

| CDCE72010, SLAS490 | 10 Outputs Low Jitter Clock Synchronizer and Jitter Cleaner | Jitter cleaner and clock synthesizer |

| CDCLVP1208, SCAS890 | Low Jitter, 2-Input Selectable 1:8 Universal-to-LVPECL Buffer | Clock buffer |

| LMK00308, SNAS576 | 3.1-GHz Differential Clock Buffer/Level Translator | Clock buffer |

| LMK01000, SNAS437 | 1.6 GHz High Performance Clock Buffer, Divider, and Distributor | Clock buffer |

| SN74AUP1T04, SCES800 | Low Power, 1.8/2.5/3.3-V Input, 3.3-V CMOS Output, Single Inverter Gate | 1.8V/2.5V/3.3V Level shifter for SPI |

| UCC28250, SLUSA29 | Advanced PWM Controller with Prebias Operation | Synchronized DC-DC power supply controller |

9.2 Typical Application

Figure 98. Application Circuit With Digital Demodulator

Figure 98. Application Circuit With Digital Demodulator

9.2.1 Design Requirements

The AFE5809 device is a highly integrated analog front-end solution. To maximize its performance, users must carefully optimize its surrounding circuits, such as T/R switch, Vcntl circuits, audio ADCs for CW path, clock distribution network, synchronized power supplies and digital processors. Typical requirements for a traditional medical ultrasound imaging system are shown in Table 26.

Table 26. Design Parameters

| PARAMETER | EXAMPLE VALUES |

|---|---|

| Signal center frequency (f0) | 1~20 MHz |

| Signal Bandwidth (BW) | 10~100% of f0 |

| Overloaded signals due to T/R switch leakage | ~2 Vpp |

| Maximum input signal amplitude | 100 mVpp to 1 Vpp |

| Transducer noise level | 1 nV/rtHz |

| Dynamic range | 151 dBc/Hz |

| Time gain compensation range | 40 dB |

| Total harmonic distortion | 40 dBc at 5MHz |

9.2.2 Detailed Design Procedure

Medical ultrasound imaging is a widely-used diagnostic technique that enables visualization of internal organs, their size, structure, and blood flow estimation. An ultrasound system uses a focal imaging technique that involves time shifting, scaling, and intelligently summing the echo energy using an array of transducers to achieve high imaging performance. The concept of focal imaging provides the ability to focus on a single point in the scan region. By subsequently focusing at different points, an image is assembled.

When initiating an imaging, a pulse is generated and transmitted from each of the 64 transducer elements. The pulse, now in the form of mechanical energy, propagates through the body as sound waves, typically in the frequency range of 1MHz to 15 MHz. The sound waves are attenuated as they travel through the objects being imaged, and the attenuation coefficients ɑ are about 0.54 dB/(MHz×cm) in soft tissue and 6~10 dB/(MHz×cm) in bone as shown in many published papers. Most medical ultrasound systems use the reflection imaging mode and the total signal attenuation is calculated by 2×depth×ɑ×f0. As the signal travels, portions of the wave front energy are reflected. Signals that are reflected immediately after transmission are very strong because they are from reflections close to the surface; reflections that occur long after the transmit pulse are very weak because they are reflecting from deep in the body. As a result of the limitations on the amount of energy that can be put into the imaging object, the industry developed extremely sensitive receive electronics with wide dynamic range.

Receive echoes from focal points close to the surface require little, if any, amplification. This region is referred to as the near field. However, receive echoes from focal points deep in the body are extremely weak and must be amplified by a factor of 100 or more. This region is referred to as the far field. In the high-gain (far field) mode, the limit of performance is the sum of all noise sources in the receive chain. In high-gain (far field) mode, system performance is defined by its overall noise level, which is limited by the noise level of the transducer assembly and the receive low-noise amplifier (LNA). However in the low-gain (near field) mode, system performance is defined by the maximum amplitude of the input signal that the system can handle. The ratio between noise levels in high-gain mode and the signal amplitude level in low-gain mode is defined as the dynamic range of the system. The high integration and high dynamic range of the device make it ideally suited for ultrasound imaging applications.

The device includes an integrated LNA and VCAT (which use the gain that can be changed with enough time to handle both near- and far-field systems), a low-pass anti-aliasing filter to limit the noise bandwidth, an ADC with high SNR performance, and a CW mixer.

Use the following steps to design medical ultrasound imaging systems:

- Use the signal center frequency and signal bandwidth to select an appropriate ADC sampling frequency.

- Use the time gain compensation range to select the range of the VCNTL signal.

- Use the transducer noise level and maximum input signal amplitude to select the appropriate LNA gain. The device input-referred noise level reduces with higher LNA gain. However, higher LNA gain leads to lower input signal swing support.

- Select different passive components for different device pins.

- Select the appropriate input termination configuration.

- Select the clock configuration for the ADC and CW clocks

9.2.2.1 LNA Configuration

9.2.2.1.1 LNA Input Coupling and Decoupling

The LNA closed-loop architecture is internally compensated for maximum stability without the need of external compensation components. The LNA inputs are biased at 2.4 V and AC coupling is required. Figure 99 shows a typical input configuration. CIN is the input AC coupling capacitor. CACT is a part of the active termination feedback path. Even if the active termination is not used, the CACT is required for the clamp functionality. The recommended values for CACT is ≥1 µF and CIN is ≥0.1 µF. A pair of clamping diodes is commonly placed between the T/R switch and the LNA input. Schottky diodes with suitable forward drop voltage (for example: the BAT754/54 series, the BAS40 series, the MMBD7000 series, or similar) can be considered depending on the transducer echo amplitude.

Figure 99. LNA Input Configurations

Figure 99. LNA Input Configurations

This architecture minimizes any loading of the signal source that may lead to a frequency-dependent voltage divider. The closed-loop design yields low offsets and offset drift. CBYPASS (≥0.015 µF) is used to set the HPF cut-off frequency and decouple the complementary input. Its cut-off frequency is inversely proportional to the CBYPASS value. The HPF cut-off frequency can be adjusted through the register 59[3:2] Table 27 lists. Low-frequency signals at T/R switch output, such as signals with slow ringing, can be filtered out. In addition, the HPF can minimize system noise from DC-DC converters, pulse repetition frequency (PRF) trigger, and frame clock. Most ultrasound systems’ signal-processing unit includes digital HPFs or band-pass filters (BPFs) in FPGAs or ASICs. Further noise suppression can be achieved in these blocks. In addition, a digital HPF is available in the AFE5809 ADC. If low-frequency signal detection is desired in some applications, the LNA HPF can be disabled.

Table 27. LNA HPF Settings (CBYPASS = 15 nF)

| Reg59[3:2] (0x3B[3:2]) | FREQUENCY (kHz) |

|---|---|

| 00 | 100 |

| 01 | 50 |

| 10 | 200 |

| 11 | 150 |

CM_BYP and VHIGH pins, which generate internal reference voltages, must be decoupled with ≥1-µF capacitors. Bigger bypassing capacitors (>2.2 µF) may be beneficial if low-frequency noise exists in the system.

9.2.2.1.2 LNA Noise Contribution

The noise specification is critical for LNA and it determines the dynamic range of the entire system. The LNA of the AFE5809 device achieves low power and an exceptionally low-noise voltage of 0.63 nV/√Hz, and a low current noise of 2.7 pA/√Hz.

Typical ultrasonic transducer’s impedance, RS, varies from tens of Ω to several hundreds of Ω. Voltage noise is the dominant noise in most cases; however, the LNA current noise flowing through the source impedance (RS) generates additional voltage noise.

The AFE5809 device achieves low-noise figure (NF) over a wide range of source resistances as shown in Figure 32, Figure 33, and Figure 34.

9.2.2.1.3 Active Termination

In ultrasound applications, signal reflection exists due to long cables between the transducer and system. The reflection results in extra ringing added to echo signals in PW mode. Because the axial resolution depends on echo signal length, such ringing effect can degrade the axial resolution. Therefore, either passive termination or active termination is preferred if good axial resolution is desired. Figure 100 shows three termination configurations.

Figure 100. Termination Configurations

Figure 100. Termination Configurations

Under the no termination configuration, the input impedance of the AFE5809 is about 6 kΩ (8 K//20 pF) at 1 MHz. Passive termination requires external termination resistor Rt, which contributes to additional thermal noise.

The LNA supports active termination with programmable values, as shown in Figure 101 .

Figure 101. Active Termination Implementation

Figure 101. Active Termination Implementation

The AFE5809 device has four pre-settings 50, 100, 200, and 400 Ω, which are configurable through the registers. Other termination values can be realized by setting the termination switches shown in Figure 101. Register [52] is used to enable these switches. The input impedance of the LNA under the active termination configuration approximately follows:

Table 5 lists the LNA RINs under different LNA gains. System designers can achieve fine tuning for different probes.

The equivalent input impedance is given by Equation 14 where RIN (8 kΩ) and CIN (20 pF) are the input resistance and capacitance of the LNA.

Therefore, the ZIN is frequency dependent, and it decreases as frequency increases as shown in Figure 10. Because 2 to 10 MHz is the most commonly used frequency range in medical ultrasound, this rolling-off effect does not impact system performance greatly. Active termination can be applied to both CW and TGC modes. Because each ultrasound system includes multiple transducers with different impedances, the flexibility of impedance configuration is a great plus.

Figure 32, Figure 33, and Figure 34 show the NF under different termination configurations. It indicates that no termination achieves the best noise figure; active termination adds less noise than passive termination. Thus, termination topology should be carefully selected based on each use scenario in ultrasound.

9.2.2.1.4 LNA Gain Switch Response

The LNA gain is programmable through SPI. The gain switching time depends on the SPI speed as well as the LNA gain response time. During the switching, glitches might occur and they can appear as artifacts in images. In addition, the signal chain needs about 14 µs to settle after the LNA gain change. Thus, LNA gain switching may not be preferred when switching time or settling time for the signal chain is limited.

9.2.2.2 Voltage-Controlled Attenuator

The attenuator in the AFE5809 device is controlled by a pair of differential control inputs, the VCNTLM,P pins. The differential control voltage spans from 0 to 1.5 V. This control voltage varies the attenuation of the attenuator based on its linear-in-dB characteristic. Its maximum attenuation (minimum channel gain) appears at VCNTLP – VCNTLM = 1.5 V and minimum attenuation (maximum channel gain) occurs at VCNTLP – VCNTLM = 0. The typical gain range is 40 dB and remains constant, independent of the PGA setting.

When only single-ended VCNTL signal is available, this 1.5-Vpp signal can be applied on the VCNTLP pin with the VCNTLM pin connected to ground; As Figure 102 show, the TGC gain curve is inversely proportional to the VCNTLP – VCNTLM.

Figure 102. VCNTLP and VCNTLM Configurations

Figure 102. VCNTLP and VCNTLM Configurations

As discussed in the theory of operation, the attenuator architecture uses seven attenuator segments that are equally spaced to approximate the linear-in-dB gain-control slope. This approximation results in a monotonic slope; the gain ripple is typically less than ±0.5 dB.

The control voltage input (VCNTLM,P pins) represents a high-impedance input. The VCNTLM,P pins of multiple AFE5809 devices can be connected in parallel with no significant loading effects. When the voltage level (VCNTLP – VCNTLM) is above 1.5 V or below 0 V, the attenuator continues to operate at its maximum attenuation level or minimum attenuation level, respectively. TI recommends lmiting the voltage from –0.3 to 2 V.

When the AFE5809 device operates in CW mode, the attenuator stage remains connected to the LNA outputs. Therefore, TI recommends powering down the VCA using the PDN_VCA register bit. In this case, VCNTLP – VCNTLM voltage does not matter.

The AFE5809 gain-control input has a –3-dB bandwidth of approximately 800 kHz. This wide bandwidth, although useful in many applications (for example, fast VCNTL response), can also allow high-frequency noise to modulate the gain control input and finally affect the Doppler performance. In practice, this modulation can be avoided by additional external filtering (RVCNTL and CVCNTL) at VCNTLM,P pins as Figure 81 shows. However, the external filter's cutoff frequency cannot be kept too low as this results in low gain response time. Without external filtering, the gain control response time is typically less than 1 μs to settle within 10% of the final signal level of 1VPP (–6-dBFS) output as indicated in Figure 51 and Figure 52.

Typical VCNTLM,P signals are generated by an 8- to 12-bit 10-MSPS digital-to-analog converter (DAC) and a differential operation amplifier. TI’s DACs, such as TLV5626 and DAC7821/11 (10 MSPS/12 bit), could be used to generate TGC control waveforms. Differential amplifiers with output common mode voltage control (that is, THS4130 and OPA1632) can connect the DAC to the VCNTLM/P pins. The buffer amplifier can also be configured as an active filter to suppress low-frequency noise. The VCNTLM/P circuit achieves low noise to prevent the VCNTLM/P noise being modulated to RF signals. TI recommends that VCNTLM/P noise is below 25 nV/rtHz at 1 kHz and 5 nV/rtHz at 50 kHz. In high-channel count premium systems, the VCNTLM/P noise requirement is higher. See Figure 103

Figure 103. Allowed Noise on the VCNTL Signal Across Frequency and Different Channels

Figure 103. Allowed Noise on the VCNTL Signal Across Frequency and Different Channels

More information can be found in SLOS318 and SBAA150. See Figure 2 for the VCNTL vs Gain curves. Table 28 also shows the absolute gain vs VCNTL, which may help program DAC correspondingly.

In PW Doppler and color Doppler modes, VCNTL noise should be minimized to achieve the best close-in phase noise and SNR. Digital VCNTL feature is implemented to address this need in the AFE5809. In the digital VCNTL mode, no external VCNTL is needed.

Table 28. VCNTLP – VCNTLM vs Gain Under Different LNA and PGA Gain Settings (Low-Noise Mode)

| VCNTLP – VCNTLM

(V) |

Gain (dB) LNA = 12 dB PGA = 24 dB |

Gain (dB) LNA = 18 dB PGA = 24 dB |

Gain (dB) LNA = 24 dB PGA = 24 dB |

Gain (dB) LNA = 12 dB PGA = 30 dB |

Gain (dB) LNA = 18 dB PGA = 30 dB |

Gain (dB) LNA = 24 dB PGA = 30 dB |

|---|---|---|---|---|---|---|

| 0 | 36.45 | 42.45 | 48.45 | 42.25 | 48.25 | 54.25 |

| 0.1 | 33.91 | 39.91 | 45.91 | 39.71 | 45.71 | 51.71 |

| 0.2 | 30.78 | 36.78 | 42.78 | 36.58 | 42.58 | 48.58 |

| 0.3 | 27.39 | 33.39 | 39.39 | 33.19 | 39.19 | 45.19 |

| 0.4 | 23.74 | 29.74 | 35.74 | 29.54 | 35.54 | 41.54 |

| 0.5 | 20.69 | 26.69 | 32.69 | 26.49 | 32.49 | 38.49 |

| 0.6 | 17.11 | 23.11 | 29.11 | 22.91 | 28.91 | 34.91 |

| 0.7 | 13.54 | 19.54 | 25.54 | 19.34 | 25.34 | 31.34 |

| 0.8 | 10.27 | 16.27 | 22.27 | 16.07 | 22.07 | 28.07 |

| 0.9 | 6.48 | 12.48 | 18.48 | 12.28 | 18.28 | 24.28 |

| 1 | 3.16 | 9.16 | 15.16 | 8.96 | 14.96 | 20.96 |

| 1.1 | –0.35 | 5.65 | 11.65 | 5.45 | 11.45 | 17.45 |

| 1.2 | –2.48 | 3.52 | 9.52 | 3.32 | 9.32 | 15.32 |

| 1.3 | –3.58 | 2.42 | 8.42 | 2.22 | 8.22 | 14.22 |

| 1.4 | –4.01 | 1.99 | 7.99 | 1.79 | 7.79 | 13.79 |

| 1.5 | –4 | 2 | 8 | 1.8 | 7.8 | 13.8 |

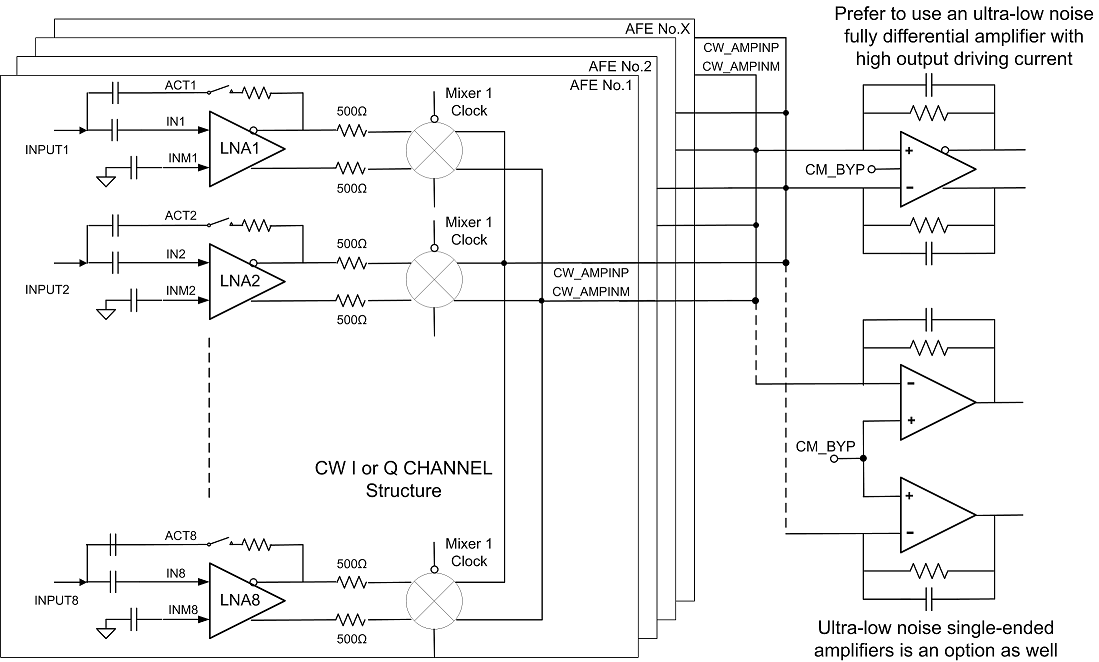

9.2.2.3 CW Operation

9.2.2.3.1 CW Summing Amplifier

To simplify CW system design, a summing amplifier is implemented in the AFE5809 to sum and convert 8-channel mixer current outputs to a differential voltage output. Low noise and low power are achieved in the summing amplifier while maintaining the full dynamic range required in CW operation.

This summing amplifier has five internal gain adjustment resistors which can provide 32 different gain settings (register 54[4:0], Figure 101 and Table 8). System designers can easily adjust the CW path gain depending on signal strength and transducer sensitivity. For any other gain values, an external resistor option is supported. The gain of the summation amplifier is determined by the ratio between the 500-Ω resistors after LNA and the internal or external resistor network REXT/INT. Thus, the matching between these resistors plays a more important role than absolute resistor values. Better than 1% matching is achieved on chip. Due to process variation, the absolute resistor tolerance could be higher. If external resistors are used, the gain error between I/Q channels or among multiple AFEs may increase. TI recommends using internal resistors to set the gain to achieve better gain matching (across channels and multiple AFEs). With the external capacitor CEXT , this summing amplifier has first-order LPF response to remove high-frequency components from the mixers, such as 2f0±fd. Its cut-off frequency is determined by:

When different gain is configured through Register 54[4:0], the LPF response varies as well.

Figure 104. CW Summing Amplifier Block Diagram

Figure 104. CW Summing Amplifier Block Diagram

Multiple AFE5809 devices are usually used in parallel to expand CW beamformer channel count. The AFE5809 CW's voltage outputs can be summed and filtered externally further to achieve desired gain and filter response. AC-coupling capacitors CAC are required to block the DC component of the CW carrier signal. CAC can vary from 1 to 10 μF depending on the desired low-frequency Doppler signal from slow blood flow. Multiple AFE5809s’ I/Q outputs can be summed together with a low-noise differential amplifiers before 16, 18-bit differential audio ADCs. The TI ultralow noise differential precision amplifier OPA1632 and THS4130 are suitable devices.

Figure 106 shows an alternative current summing circuit. However, this circuit only achieves good performance when a lower-noise operational amplifier is available compared to the AFE5809's internal summing differential amplifier.

Figure 105. CW Circuit With Multiple AFE5809s (Voltage Output Mode)

Figure 105. CW Circuit With Multiple AFE5809s (Voltage Output Mode)

The CW I/Q channels are well matched internally to suppress image frequency components in the Doppler spectrum. Low-tolerance components and precise operational amplifiers should be used for achieving good matching in the external circuits as well.

NOTE

The local oscillator inputs of the passive mixer are cos(ωt) for I-CH and sin(ωt) for Q-CH, respectively. Depending on the users' CW Doppler complex FFT processing, swapping I/Q channels in FPGA or DSP may be needed to get correct blood flow directions.

9.2.2.3.2 CW Clock Selection

The AFE5809 device can accept differential LVDS, LVPECL, and other differential clock inputs as well as single-ended CMOS clock. An internally generated VCM of 2.5 V is applied to CW clock inputs, that is, CLKP_16X/ CLKM_16X and CLKP_1X/ CLKM_1X. Because this 2.5-V VCM is different from the one used in standard LVDS or LVPECL clocks, AC coupling is required between clock drivers and the AFE5809 CW clock inputs. When the CMOS clock is used, CLKM_1X and CLKM_16X should be tied to ground. Figure 107 shows common clock configurations. TI recommends appropriate termination to achieve good signal integrity.

Figure 107. Clock Configurations

Figure 107. Clock Configurations

The combination of the clock noise and the CW path noise can degrade the CW performance. The internal clocking circuit is designed for achieving excellent phase noise required by CW operation. The phase noise of the AFE5809 CW path is better than 155 dBc/Hz at 1-kHz offset. Consequently, the phase noise of the mixer clock inputs needs to be better than 155 dBc/Hz.

In the 16/8/4 × ƒcw operations modes, low phase noise clock is required for 16, 8, 4 × ƒcw clocks (that is, CLKP_16X/ CLKM_16X pins) to maintain good CW phase noise performance. The 1 × ƒcw clock (that is, CLKP_1X/ CLKM_1X pins) is only used to synchronize the multiple AFE5809 chips and is not used for demodulation. Thus, 1 × ƒcw clock’s phase noise is not a concern. However, in the 1 × ƒcw operation mode, low-phase noise clocks are required for both CLKP_16X/ CLKM_16X and CLKP_1X/ CLKM_1X pins because both of them are used for mixer demodulation. In general, a higher slew rate clock has lower phase noise; thus, clocks with high amplitude and fast slew rate are preferred in CW operation. In the CMOS clock mode, a 5-V CMOS clock can achieve the highest slew rate.

Clock phase noise can be improved by a divider as long as the divider’s phase noise is lower than the target phase noise. The phase noise of a divided clock can be improved approximately by a factor of 20logN dB where N is the dividing factor of 16, 8, or 4. If the target phase noise of mixer LO clock 1 × ƒcw is 160 dBc/Hz at 1 kHz off carrier, the 16 × ƒcw clock phase noise should be better than 160 – 20log16 = 136 dBc/Hz. TI’s jitter cleaners LMK048X/CDCM7005/CDCE72010 exceed this requirement and can be selected for the AFE5809. In the 4×/1× modes, higher-quality input clocks are expected to achieve the same performance because N is smaller. Thus, the 16× mode is a preferred mode because it reduces the phase noise requirement for system clock design. In addition, the phase delay accuracy is specified by the internal clock divider and distribution circuit. Note in the 16× operation mode, the CW operation range is limited to 8 MHz due to the 16× CLK. The maximum clock frequency for the 16× CLK is 128 MHz. In the 8×, 4×, and 1× modes, higher CW signal frequencies up to 15 MHz can be supported with small degradation in performance, for example, the phase noise is degraded by 9 dB at 15 MHz, compared to 2 MHz.

As the channel number in a system increases, clock distribution becomes more complex. It is not preferred to use one clock driver output to drive multiple AFEs because the clock buffer’s load capacitance increases by a factor of N. As a result, the falling and rising time of a clock signal is degraded. A typical clock arrangement for multiple AFE5809 devices is shown in Figure 108. Each clock buffer output drives one AFE5809 device to achieve the best signal integrity and fastest slew rate, that is, better phase noise performance. When clock phase noise is not a concern, for example, the 1 × ƒcw clock in the 16, 8, 4 × ƒcw operation modes, one clock driver output may excite more than one AFE5809 device. Nevertheless, special considerations should be applied in such a clock distribution network design. In typical ultrasound systems, it is preferred that all clocks are generated from a same clock source, such as 16 × ƒcw , 1 × ƒcw clocks, audio ADC clocks, RF ADC clock, pulse repetition frequency signal, frame clock, and so on. By doing this, interference due to clock asynchronization can be minimized.

Figure 108. CW Clock Distribution

Figure 108. CW Clock Distribution

9.2.2.3.3 CW Supporting Circuits

As a general practice in CW circuit design, in-phase and quadrature channels should be strictly symmetrical by using well-matched layout and high-accuracy components.

In systems, additional high-pass wall filters (20 to 500 Hz) and low-pass audio filters (10 to 100 kHz) with multiple poles are usually needed. Because the CW Doppler signal ranges from 20 Hz to 20 kHz, noise under this range is critical. Consequently, low-noise audio operational amplifiers are suitable to build these active filters for CW post-processing, that is, OPA1632 or OPA2211. To find more filter design techniques, see www.ti.com. For the TI active filter design tool, see www.ti.com/filterdesigner.

The filtered audio CW I/Q signals are sampled by audio ADCs and processed by DSP or PC. Although CW signal frequency is from 20 Hz to 20 kHz, higher sampling rate ADCs are still preferred for further decimation and SNR enhancement. Due to the large dynamic range of CW signals, high resolution ADCs (≥16 bit) are required, such as ADS8413 (2 MSPS, 16-bit, 92-dBFS SNR) and ADS8472 (1 MSPS, 16-bit, 95-dBFS SNR). ADCs for in-phase and quadrature-phase channels must be strictly matched, not only amplitude matching but also phase matching, to achieve the best I/Q matching. In addition, the in-phase and quadrature ADC channels must be sampled simultaneously.

9.2.2.4 Low Frequency Support

In addition, the signal chain of the AFE5809 can handle signal frequency lower than 100 kHz, which enables the AFE5809 to be used in both sonar and medical applications. The PGA integrator must be turned off to enable the low frequency support. Meanwhile, a large capacitor like 1 µF can be used for setting low corner frequency of the LNA DC offset correction circuit as shown in Figure 62. See Figure 59 to find AFE5809's low frequency response.

9.2.2.5 ADC Operation

9.2.2.5.1 ADC Clock Configurations

To ensure that the aperture delay and jitter are the same for all channels, the AFE5809 uses a clock tree network to generate individual sampling clocks for each channel. The clock, for all the channels, are matched from the source point to the sampling circuit of each of the eight internal ADCs. The variation on this delay is described in the aperture delay parameter of the output interface timing. Its variation is given by the aperture jitter number of the same table.

Figure 109. ADC Clock Distribution Network

Figure 109. ADC Clock Distribution Network

The AFE5809 ADC clock input can be driven by differential clocks (sine wave, LVPECL, or LVDS) or singled clocks (LVCMOS) similar to CW clocks as shown in Figure 107. In the single-end case, TI recommends that the use of low jitter square signals (LVCMOS levels, 1.8-V amplitude). See TI document SLYT075 for further details on the theory.

The jitter cleaner CDCM7005 or CDCE72010 is suitable to generate the AFE5809’s ADC clock and ensure the performance for the14-bit ADC with 77-dBFS SNR. Figure 109 shows a clock distribution network.

9.2.2.5.2 ADC Reference Circuit

The ADC’s voltage reference can be generated internally or provided externally. When the internal reference mode is selected, the REFP/M become output pins and should be floated. When 3[15] = 1 and 1[13] = 1, the device is configured to operate in the external reference mode in which the VREF_IN pin should be driven with a 1.4-V reference voltage and REFP/M must be left open. Because the input impedance of the VREF_IN is high, no special drive capability is required for the 1.4-V voltage reference

The digital beam-forming algorithm in an ultrasound system relies on gain matching across all receiver channels. A typical system would have about 12 octal AFEs on the board. In such a case, it is critical to ensure that the gain is matched, essentially requiring the reference voltages seen by all the AFEs to be the same. Matching references within the eight channels of a chip is done by using a single internal reference voltage buffer. Trimming the reference voltages on each chip during production ensures that the reference voltages are well-matched across different chips. When the external reference mode is used, a solid reference plane on a PCB can ensure minimal voltage variation across devices. More information on voltage reference design can be found in the document SLYT339.

The dominant gain variation in the AFE5809 comes from the VCA gain variation. The gain variation contributed by the ADC reference circuit is much smaller than the VCA gain variation. Hence, in most systems, using the ADC internal reference mode is sufficient to maintain good gain matching among multiple AFE5809s. In addition, the internal reference circuit without any external components achieves satisfactory thermal noise and phase noise performance.

9.2.3 Application Curves

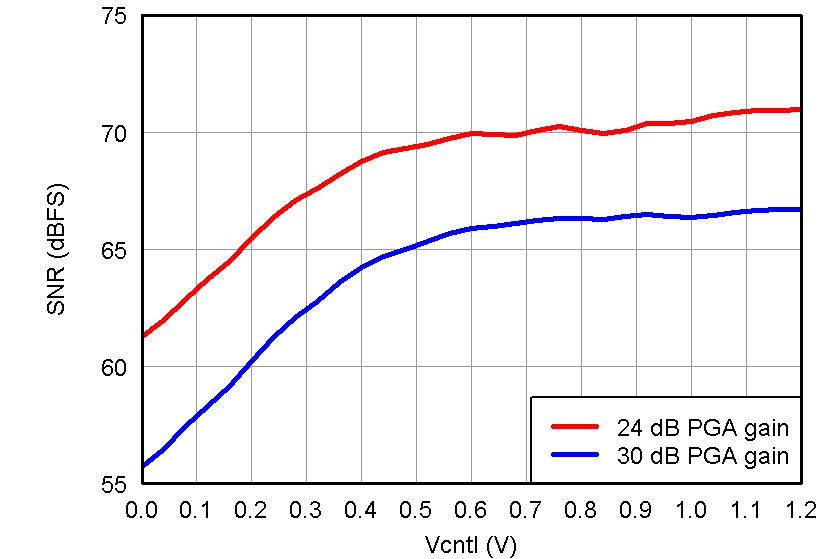

Figure 110 show the output SNR of one AFE channel from VCNTL = 0 V and VCNTL = 1.2 V, respectively, with an input signal at 5 MHz captured at a sample rate of 65 MHz. VCNTL = 0 V represents far field while VCNTL = 1.2 V represents near field.Figure 111 shows the CW phase noise or dyanmic range of a singe AFE channel.

Figure 110. SNR vs. Vcntl at 18 dB LNA

Figure 110. SNR vs. Vcntl at 18 dB LNA

Figure 111. CW Phase Noise at Fin = 2 MHz

Figure 111. CW Phase Noise at Fin = 2 MHz

9.3 System Example

In a complex system design, system debug features of a device are very important. The AFE5809 includes multiple test modes to accelerate system development.

9.3.1 ADC Debug

The ADC test modes are discussed in the ADC register description section. The AFE5809 device can output a variety of test patterns on the LVDS outputs. These test patterns replace the normal ADC data output. The device may also be made to output 6 preset patterns:

- Ramp: Setting Register 2[15:13] = 111 causes all the channels to output a repeating full-scale ramp pattern. The ramp increments from zero code to full-scale code in steps of 1 LSB every clock cycle. After hitting the full-scale code, it returns back to zero code and ramps again.

- Zeros: The device can be programmed to output all 0 s by setting Register 2[15:13] = 110.

- Ones: The device can be programmed to output all 1 s by setting Register 2[15:13] = 100.

- Deskew Patten: When 2[15:13] = 010; this mode replaces the 14-bit ADC output with the 01010101010101 word.

- Sync Pattern: When 2[15:13] = 001, the normal ADC output is replaced by a fixed 11111110000000 word.

- Toggle: When 2[15:13] = 101, the normal ADC output is alternating from 1 s to 0 s. The start state of ADC word can be either 1 s or 0 s.

- Custom Pattern: It can be enabled when 2[15:13] = 011. Users can write the required VALUE into register bits <CUSTOM PATTERN>, which is Register 5[13:0]. Then, the device will output VALUE at its outputs, about 3 to 4 ADC clock cycles after the 24th rising edge of SCLK. So, the time taken to write one value is 24 SCLK clock cycles + 4 ADC clock cycles. To change the customer pattern value, users can repeat writing Register 5[13:0] with a new value. Due to the speed limit of SPI, the refresh rate of the custom pattern may not be high. For example, 128 points custom pattern takes approximately 128 × (24 SCLK clock cycles + 4 ADC clock cycles).

NOTE

Only one of the above patterns can be active at any given instant. Test pattern from the ADC output stage can NOT be sent to the demodulator; it can only be sent to the LVDS serializer when the demodulator is off.

NOTE

After the demodulator is enabled, digital demodulator register 02[15:13] can be configured to send out test patterns for demod block, please seeDigital Demodulator Register Description.

9.3.2 VCA Debug

The VCA has a test mode in which the CH7 and CH8 PGA outputs can be brought to the CW pins. By monitoring these PGA outputs, the functionality of VCA operation can be verified. The PGA outputs are connected to the virtual ground pins of the summing amplifier (CW_IP_AMPINM/P, CW_QP_AMPINM/P) through 5-kΩ resistors. The PGA outputs can be monitored at the summing amplifier outputs when the LPF capacitors CEXT are removed. The signals at the summing amplifier outputs are attenuated due to the 5-kΩ resistors. The attenuation coefficient is RINT/EXT / 5 kΩ.

If users would like to check the PGA outputs without removing CEXT, an alternative way is to measure the PGA outputs directly at the CW_IP_AMPINM/P and CW_QP_AMPINM/P when the CW summing amplifier is powered down.

Some registers are related to this test mode, PGA Test Mode Enable: Reg59[9]; Buffer Amplifier Power Down Reg59[8]; and Buffer Amplifier Gain Control Reg54[4:0]. Based on the buffer amplifier configuration, the registers can be set in different ways:

- Configuration 1

- In this configuration, the test outputs can be monitored at CW_AMPINP/M.

- Reg59[9] = 1; test mode enabled

- Reg59[8] = 0; buffer amplifier powered-down

- Configuration 2

- In this configuration, the test outputs can be monitored at CW_OUTP/M.

- Reg59[9] = 1; test mode enabled

- Reg59[8] = 1; buffer amplifier powered on

- Reg54[4:0] = 10H; internal feedback 2-kΩ resistor enabled. Different values can be used as well.

Figure 112. AFE5809 PGA Test Mode

Figure 112. AFE5809 PGA Test Mode

9.4 Do's and Don'ts

9.4.1 Driving the Inputs (Analog or Digital) Beyond the Power-Supply Rails

For device reliability, an input must not go more than 300 mV below the ground pins or 300 mV above the supply pins as suggested in the table. Exceeding these limits, even on a transient basis, can cause faulty or erratic operation and can impair device reliability.

9.4.2 Driving the Device Signal Input With an Excessively High Level Signal

The device offers consistent and fast overload recovery with a 6-dB overloaded signal. For very large overload signals (> 6 dB of the linear input signal range), TI recommends back-to-back Schottky clamping diodes at the input to limit the amplitude of the input signal. Refer to the section for more details.

9.4.3 Driving the VCNTL Signal With an Excessive Noise Source

Noise on the VCNTL signal gets directly modulated with the input signal and causes higher output noise and reduction in SNR performance. Maintain a noise level for the VCNTL signal as discussed in the section.

9.4.4 Using a Clock Source With Excessive Jitter, an Excessively Long Input Clock Signal Trace, or Having Other Signals Coupled to the ADC or CW Clock Signal Trace

These situations cause the sampling interval to vary, causing an excessive output noise and a reduction in SNR performance. For a system with multiple devices, the clock tree scheme must be used to apply an ADC or CW clock. Refer to the section for clock mismatch between devices, which can lead to latency mismatch and reduction in SNR performance. Clocks generated by FPGA may include excessive jitter and must be evaluated carefully before driving ADC or CW circuits.

9.4.5 LVDS Routing Length Mismatch

The routing length of all LVDS lines routing to the FPGA must be matched to avoid any timing related issue. For systems with multiple devices, the LVDS serialized data clock (DCLKP, DCLKM) and the frame clock (FCLKP, FCLKM) of each individual device must be used to deserialize the corresponding LVDS serialized data (DnP,DnM).

9.4.6 Failure to Provide Adequate Heat Removal

Use the appropriate thermal parameter listed in the table and an ambient, board, or case temperature to calculate device junction temperature. A suitable heat removal technique must be used to keep the device junction temperature below the maximum limit of 105°C.