SNVS867 June 2014 LM3633

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4

Device Functional Modes

- 7.4.1

High-Voltage LED Control

- 7.4.1.1 High-Voltage Boost Converter

- 7.4.1.2 High-Voltage Current Sinks (HVLED1, HVLED2 and HVLED3)

- 7.4.1.3 High-Voltage Current String Biasing

- 7.4.1.4 Boost Switching-Frequency Select

- 7.4.1.5 Automatic Switching Frequency Shift

- 7.4.1.6 Brightness Register Current Control

- 7.4.1.7 PWM Control

- 7.4.1.8 Start-up/Shutdown Ramp

- 7.4.1.9 Run-Time Ramp

- 7.4.1.10 High-Voltage Control A/B Ramp Select

- 7.4.1.11 LED Current Mapping Modes

- 7.4.1.12 Exponential Mapping

- 7.4.1.13 Linear Mapping

- 7.4.2

Low-Voltage LED Control

- 7.4.2.1 Integrated Charge Pump

- 7.4.2.2 Charge Pump Disabled

- 7.4.2.3 Automatic Gain

- 7.4.2.4 Automatic Gain (Flying Capacitor Detection)

- 7.4.2.5 1X Gain

- 7.4.2.6 2X Gain

- 7.4.2.7 Low-Voltage Current Sinks (LVLED1 to LVLED6)

- 7.4.2.8 Low-Voltage LED Biasing

- 7.4.2.9 Brightness Register Current Control

- 7.4.2.10 LED Current Mapping Modes

- 7.4.2.11 Exponential Mapping

- 7.4.2.12 Linear Mapping

- 7.4.2.13 Start-up/Shutdown Ramp

- 7.4.2.14 Run-Time Ramp

- 7.4.3 Low-Voltage LED Pattern Generator

- 7.4.4 Fault Flags/Protection Features

- 7.4.5 I2C-Compatible Interface

- 7.4.1

High-Voltage LED Control

- 7.5 Register Descriptions

-

8 Applications and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Boost Converter Maximum Output Power (Boost)

- 8.2.2.2 Boost Inductor Selection

- 8.2.2.3 Output Capacitor Selection

- 8.2.2.4 Schottky Diode Selection

- 8.2.2.5 Input Capacitor Selection

- 8.2.2.6 Maximum Output Power (Charge Pump)

- 8.2.2.7 Charge Pump Flying Capacitor Selection

- 8.2.2.8 Charge Pump Output Capacitor Selection

- 8.2.2.9 Charge Pump Input Capacitor Selection

- 8.2.3 Application Performance Plots

- 8.3 Initialization Set Up

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- YFQ|20

Thermal pad, mechanical data (Package|Pins)

Orderable Information

1 Features

- Drives Three Parallel High-Voltage LED Strings for Display and Keypad Lighting

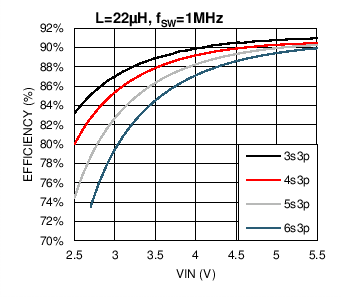

- High-Voltage Strings Capable of up to 40-V Output Voltage and up to 90% Efficiency

- Up to 30-mA per Current Sink (Both Backlight and Indicator)

- 11-Bit High-Voltage LED Dimming

- PWM Input for Content Adjustable Brightness Control (CABC)

- Integrated 1-A/40-V MOSFET

- Adaptive Boost Output to LED Voltages

- Six Low-Voltage Current Sinks for Indicator LEDs

- Integrated Charge Pump for Improved Efficiency and VIN Operating Range

- Internal Pattern Generation Engine for Each Indicator LED

- Fully Configurable LED Grouping and Control

- Four Programmable Overvoltage Protection Thresholds (16 V, 24 V, 32 V, and 40 V)

- Programmable 500-kHz and 1-MHz Switching Frequency

- Overcurrent Protection

- Thermal Shutdown Protection

- 27 mm2 Total Solution Size

2 Applications

- Power Source for Smart Phone Illumination

- Display, Keypad and Indicator Illumination

- RGB Indicator Driver

3 Description

The LM3633 11-bit LED driver provides high-performance backlight dimming for 1, 2, or 3 parallel high-voltage LED strings while delivering up to 90% efficiency. The boost converter with integrated 1-A, 40-V MOSFET automatically adjusts to LED forward voltage to minimize headroom voltage and effectively improve LED efficiency.

The LM3633 is a complete power source for backlight, keypad, and indicator LEDs in smartphone handsets. The high-voltage inductive boost converter provides the power for three parallel LED strings (HVLED1, HVLED2 and HVLED3). The integrated charge pump provides the bias for the six low-voltage indicator LEDs (LVLED1-LVLED6). All low-voltage current sinks can have a programmable pattern modulated onto their output current for a wide variety of blinking patterns.

An additional feature is a Pulse Width Modulation (PWM) control input for content adjustable backlight control, which can be used to control any high-voltage current sink.

The LM3633 is fully programmable via an I2C-compatible interface. The device operates over a 2.7-V to 5.5-V input voltage range and a −40°C to 85°C temperature range.

Device Information(1)

| PART NUMBER | PACKAGE | BODY SIZE (MAX) |

|---|---|---|

| LM3633 | DSBGA (20) | 2.04 mm x 1.78 mm |

- For all available packages, see the orderable addendum at the end of the datasheet.

Simplified Schematic

Dual String Efficiency vs VIN