SNVSAJ2C March 2016 – June 2018 LMZ34202

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Adjusting the Output Voltage

- 7.3.2 Switching Frequency (RT)

- 7.3.3 Recommended Operating Range

- 7.3.4 Synchronization (CLK)

- 7.3.5 Output Capacitor Selection

- 7.3.6 VERSA-COMP Pin Configurations

- 7.3.7 Input Capacitor Selection

- 7.3.8 Output On/Off Inhibit (INH/UVLO)

- 7.3.9 Under Voltage Lockout (UVLO)

- 7.3.10 Remote Sense

- 7.3.11 VBSEL

- 7.3.12 Soft-Start (SS/TR)

- 7.3.13 Power Good (PWRGD) and Pull-up (PWRGD_PU)

- 7.3.14 Overcurrent Protection

- 7.3.15 Thermal Shutdown

- 7.4 Device Functional Modes

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- RVQ|43

Thermal pad, mechanical data (Package|Pins)

Orderable Information

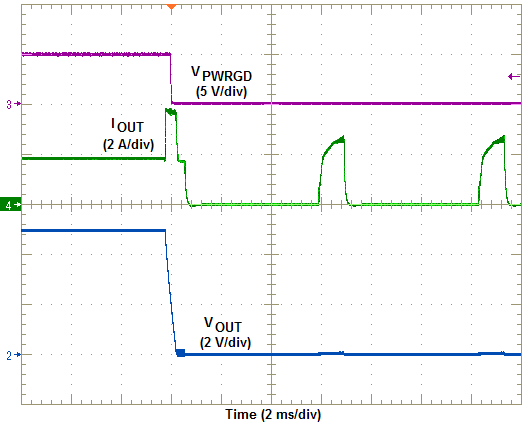

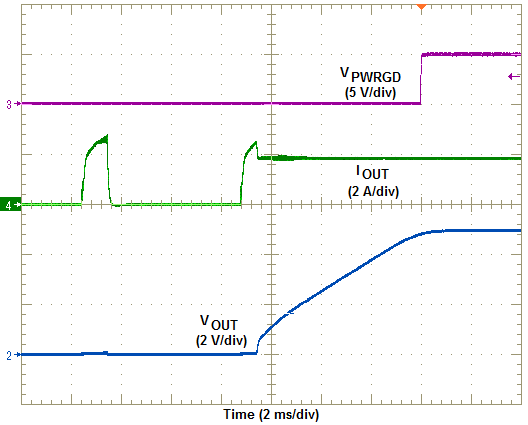

7.3.14 Overcurrent Protection

For protection against load faults, the LMZ34202 incorporates output overcurrent protection. Applying a load that exceeds the regulator's overcurrent threshold causes the output to shut down when the output voltage falls below the PWRGD threshold. Following shutdown, the module periodically attempts to recover by initiating a soft-start power-up as shown in Figure 25. This is described as a hiccup mode of operation, whereby the module continues in a cycle of successive shutdown and power up until the load fault is removed. During this period, the average current flowing into the fault is significantly reduced which reduces power dissipation. Once the fault is removed, the module automatically recovers and returns to normal operation as shown in Figure 26.

Figure 25. Overcurrent Limiting

Figure 25. Overcurrent Limiting  Figure 26. Removal of Overcurrent

Figure 26. Removal of Overcurrent