SBOS070D October 1997 – December 2019 OPA548

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10.1.2 Amplifier Mounting

Figure 46 provides recommended solder footprints for both the TO-220 and DDPAK power packages. The tab of both packages is electrically connected to the negative supply, V–. It may be desirable to isolate the tab of the TO-220 package from its mounting surface with a mica (or other film) insulator (see Figure 42). For lowest overall thermal resistance it is best to isolate the entire heat sink/OPA548 structure from the mounting surface rather than to use an insulator between the semiconductor and heat sink.

For best thermal performance, the tab of the DDPAK surface-mount version should be soldered directly to a circuit board copper area. Increasing the copper area improves heat dissipation. See Figure 43 for typical thermal resistance from junction-to-ambient as a function of the copper area.

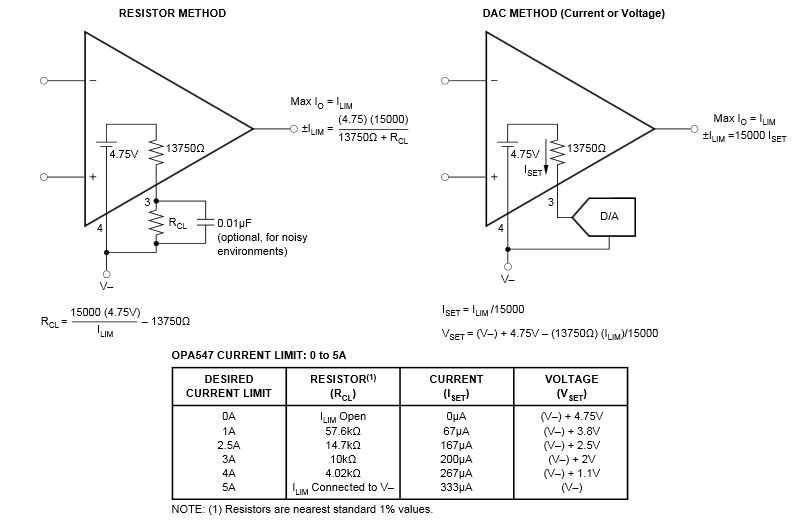

Figure 41. Adjustable Current Limit

Figure 41. Adjustable Current Limit