SLVS802C August 2009 – May 2015 TPS22932B

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics

- 7.6 Switching Characteristics, 1.2 V

- 7.7 Switching Characteristics, 1.5 V

- 7.8 Switching Characteristics, 1.8 V

- 7.9 Switching Characteristics, 2.5 V

- 7.10 Switching Characteristics, 3 V

- 7.11 Switching Characteristics, 3.3 V

- 7.12 Typical Characteristics

- 8 Parameter Measurement information

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- YFP|6

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

10.1 Application Information

10.1.1 ON and OFF Control

The ON pin controls the state of the switch. Activating ON continuously holds the switch in the on state so long as there is no fault. ON is active HI and has a low threshold making it capable of interfacing with low voltage signals. The ON pin is compatible with standard GPIO logic threshold. It can be used with any microcontroller with 1.2-V, 1.8-V, 2.5-V, or 3.3-V GPIOs.

10.1.2 Input Capacitor

To limit the voltage drop on the input supply caused by transient in-rush currents when the switch turns on into a discharged load capacitor or short-circuit, a capacitor must be placed between VIN and GND . A 1-μF ceramic capacitor, CIN, placed close to the pins is usually sufficient. Higher values of CIN can be used to further reduce the voltage drop during higher current application. When switching a heavy load, TI recommends to have an input capacitor about 10 or more times higher than the output capacitor to avoid any supply drop.

10.1.3 Output Capacitor

Due to the integral body diode in the PMOS switch, a CIN greater than CL is highly recommended. A CL greater than CIN can cause VOUT to exceed VIN when the system supply is removed. This could result in current flow through the body diode from VOUT to VIN.

10.2 Typical Application

10.2.1 Design Requirements

For this example, follow the design parameters listed in Table 3.

Table 3. Design Parameters

| DESIGN PARAMETERS | EXAMPLE VALUE | |||

|---|---|---|---|---|

| VIN | 3.3 V | |||

| CL | 4.7 µF | |||

| Maximum Acceptable Inrush Current | 150 mA | |||

10.2.2 Detailed Design Procedure

10.2.2.1 VIN to VOUT Voltage Drop

The VIN to VOUT voltage drop in the device is determined by the rON of the device and the load current. The rON of the device depends upon the VIN condition of the device. Refer to the rON specification of the device in the Electrical Characteristics table of this data sheet. When the rON of the device is determined based upon the VIN conditions, use Equation 1 to calculate the VIN to VOUT voltage drop:

where

- ΔV = Voltage drop from VIN to VOUT

- ILOAD = Load current

- rON = ON-resistance of the device for a specific VIN

- An appropriate ILOAD must be chosen such that the IMAX specification of the device is not violated.

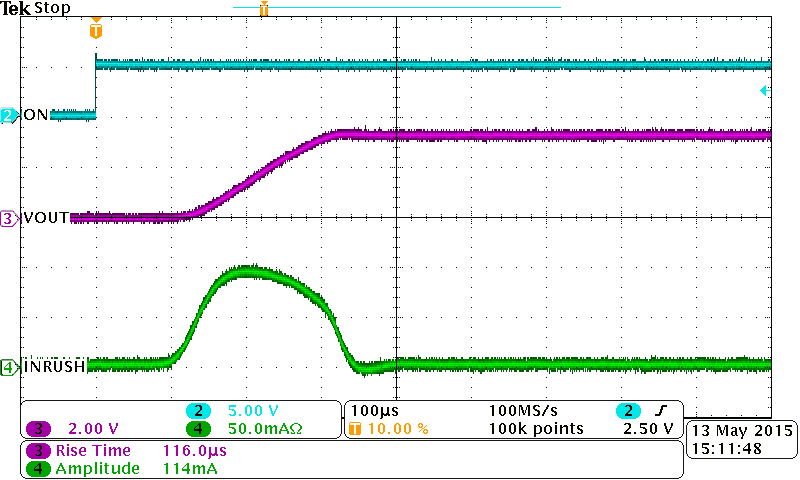

10.2.2.2 Managing Inrush Current

When the switch is enabled, the output capacitors must be charged up from 0-V to VIN. This charge arrives in the form of inrush current. Inrush current can be calculated using the following equation:

where

- C = Output capacitance

-

The TPS22932B offers a very slow controlled rise time for minimizing inrush current. This device can be selected based upon the maximum acceptable slew rate which can be calculated using the design requirements and the inrush current equation. An output capacitance of 4.7 μF will be used because the amount of inrush increases with output capacitance:

To ensure an inrush current of less than 150 mA, a device with a slew rate less than 31.9 V/ms must be used.

The TPS22932B has a typical rise time of 145 μs at 3.3 V. This results in a slew rate of 22.8 V/ms which meets the requirement.

10.2.3 Application Curve

Figure 40. TPS22932B Inrush Current With 4.7-µF Output Capacitor

Figure 40. TPS22932B Inrush Current With 4.7-µF Output Capacitor