SLVSE56 November 2017 TPS65320D-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1

Buck Regulator

- 7.3.1.1 Fixed-Frequency PWM Control

- 7.3.1.2 Slope Compensation Output

- 7.3.1.3 Pulse-Skip Eco-mode™ Control Scheme

- 7.3.1.4 Dropout Mode Operation and Bootstrap Voltage (BOOT)

- 7.3.1.5 Error Amplifier

- 7.3.1.6 Voltage Reference

- 7.3.1.7 Adjusting the Output Voltage

- 7.3.1.8 Soft-Start Pin (SS)

- 7.3.1.9 Overload-Recovery Circuit

- 7.3.1.10 Constant Switching Frequency and Timing Resistor (RT/CLK Pin)

- 7.3.1.11 Overcurrent Protection and Frequency Shift

- 7.3.1.12 Selecting the Switching Frequency

- 7.3.1.13 How to Interface to RT/CLK Pin

- 7.3.1.14 Overvoltage Transient Protection

- 7.3.1.15 Small-Signal Model for Loop Response

- 7.3.1.16 Simple Small-Signal Model for Peak-Current Mode Control

- 7.3.1.17 Small-Signal Model for Frequency Compensation

- 7.3.2 LDO Regulator

- 7.3.3 Thermal Shutdown

- 7.3.4 Power-Good Output, nRST

- 7.3.5 Enable and Undervoltage Lockout

- 7.3.1

Buck Regulator

- 7.4 Device Functional Modes

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1

2.2-MHzSwitching Frequency, 9-V to 16-V Input, 5-V Output Buck Regulator, 3.3-V Output LDO Regulator

- 8.2.1.1 Design Requirements

- 8.2.1.2

Detailed Design Procedure

- 8.2.1.2.1 Switching Frequency Selection for the Buck Regulator

- 8.2.1.2.2 Output Inductor Selection for the Buck Regulator

- 8.2.1.2.3 Output Capacitor Selection for the Buck Regulator

- 8.2.1.2.4 Catch Diode Selection for the Buck Regulator

- 8.2.1.2.5 Input Capacitor Selection for the Buck Regulator

- 8.2.1.2.6 Soft-Start Capacitor Selection for the Buck Regulator

- 8.2.1.2.7 Bootstrap Capacitor Selection for the Buck Regulator

- 8.2.1.2.8 Output Voltage and Feedback Resistor Selection for the Buck Regulator

- 8.2.1.2.9 Frequency Compensation Selection for the Buck Regulator

- 8.2.1.2.10 LDO Regulator

- 8.2.1.2.11 Power Dissipation

- 8.2.1.2.12 Power Dissipation Losses of the LDO Regulator

- 8.2.1.2.13 Total Device Power Dissipation Losses and Junction Temperature

- 8.2.1.3 Application Curves

- 8.2.1

2.2-MHzSwitching Frequency, 9-V to 16-V Input, 5-V Output Buck Regulator, 3.3-V Output LDO Regulator

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- PWP|14

Thermal pad, mechanical data (Package|Pins)

- PWP|14

Orderable Information

7 Detailed Description

7.1 Overview

The TPS65320D-Q1 device is a 36-V, 3.2-A, DC-DC step-down converter (also referred to as a buck regulator) with a 280-mA low-dropout (LDO) linear regulator. Both of these regulators have low quiescent consumption during a light load to prolong battery life.

The buck regulator improves performance during line and load transients by implementing a constant-frequency and current-mode control (CCM) that reduces output capacitance which simplifies external frequency-compensation design. The wide switching frequency of 100 kHz to 2500 kHz allows for efficiency and size optimization when selecting the output-filter components. The switching frequency is adjusted by using a resistor to ground on the RT/CLK pin. The buck regulator has an internal phase-locked loop (PLL) on the RT/CLK pin that synchronizes the power-switch turnon to the falling edge of an external system clock.

The TPS65320D-Q1 device reduces the external component count by integrating the boot recharge diode. A capacitor between the BOOT pin and the SW pin supplies the bias voltage for the integrated high-side MOSFET. The output voltage can step-down to as low as the 0.8-V reference. The soft start minimizes inrush currents and provides power-supply sequencing during power up. Connect a small-value capacitor to the pin to adjust the soft-start time. For critical power-supply sequencing requirements couple a resistor divider to the pin.

The LDO regulator consumes only about a 35-µA current in light load. The LDO regulator also tracks the battery when the battery voltage is low (in a cold-crank condition).The input of the LDO regulator has a unique auto-source feature which sources the input supply from either the buck output or the battery. If both the buck and LDO regulators are enabled, the buck regulator switches the input of the LDO regulator to the output of the buck to reduce heat. With the buck disabled or the buck output voltage out of regulation (VFB1 less than 91% of Vref), the buck regulator switches the LDO input automatically to the input voltage.

The LDO regulator of the TPS65320D-Q1 device has a power-good comparator (nRST) that asserts when the regulated output voltage is less than 92% (typical) of the nominal output voltage.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 Buck Regulator

7.3.1.1 Fixed-Frequency PWM Control

The TPS65320D-Q1 buck regulator uses an adjustable, fixed-frequency peak current-mode control. An internal voltage reference compares the output voltage through external resistors on the FB1 pin to an error amplifier which drives the COMP pin. An internal oscillator initiates the turnon of the high-side power switch. The device compares the error amplifier output to the high-side power-switch current. When the power-switch current reaches the level set by the COMP voltage, the power switch turns off. The COMP pin voltage increases and decreases as the output current increases and decreases. The device implements a current-limit by clamping the COMP pin voltage to a maximum level.

7.3.1.2 Slope Compensation Output

The TPS65320D-Q1 buck regulator adds a compensating ramp to the switch-current signal. This slope compensation prevents sub-harmonic oscillations. The available peak-inductor current remains constant over the full duty-cycle range.

7.3.1.3 Pulse-Skip Eco-mode™ Control Scheme

The TPS65320D-Q1 buck regulator operates in a pulse-skip mode at light load currents to improve efficiency by reducing switching and gate-drive losses. The design of the TPS65320D-Q1 buck regulator is such that if the output voltage is within regulation and the peak switch current at the end of any switching cycle is below the pulse-skipping-current threshold, the buck regulator enters pulse-skip mode. This current threshold is the current level corresponding to a nominal COMP voltage, or 720 mV. The current at which entry to the pulse-skip mode occurs depends on switching frequency, inductor selection, output-capacitor selection, and compensation network.

In pulse-skip mode, the buck regulator clamps the COMP pin voltage at 720 mV, inhibiting the high-side MOSFET. Further decreases in load current or in output voltage cannot drive the COMP pin below this clamp-voltage level. Because the buck regulator is not switching, the output voltage begins to decay. As the voltage-control loop compensates for the falling output voltage, the COMP pin voltage begins to rise. At this time, the high-side MOSFET turns on and a switching pulse initiates on the next switching cycle. The peak current is set by the COMP pin voltage. The output current recharges the output capacitor to the nominal voltage, then the peak switch current begins to decrease, and eventually falls below the pulse-skip-mode threshold, at which time the buck regulator enters Eco-mode again.

For pulse-skip-mode operation, the TPS65320D-Q1 buck regulator senses the peak current, not the average or load current. Therefore, the load current where the buck regulator enters pulse-skip mode is dependent on the output inductor value. When the load current is low and the output voltage is within regulation, the buck regulator enters a sleep mode and draws only 140-µA input quiescent current. The internal PLL remains operating when the buck regulator is in sleep mode.

7.3.1.4 Dropout Mode Operation and Bootstrap Voltage (BOOT)

The TPS65320D-Q1 buck regulator has an integrated boot regulator and requires a small ceramic capacitor between the BOOT pin and the SW pin to provide the gate-drive voltage for the high-side MOSFET. The BOOT capacitor recharges when the high-side MOSFET is off and the low-side diode conducts. The value of this ceramic capacitor must be 0.1 μF. TI recommends a ceramic capacitor with an X7R or X5R grade dielectric and a voltage rating of 10 V or higher because of the stable characteristics over temperature and over voltage.

To improve drop out, the high-side MOSFET of the TPS65320D-Q1 buck regulator remains on for 7 consecutive switching cycles, and is forced off during the 8th switching cycle to allow the low-side diode to conduct and refresh the charge on the BOOT capacitor. Because the current supplied by the BOOT capacitor is low, the high-side MOSFET can remain on before it is required to refresh the BOOT capacitor. The effective duty cycle of the switching regulator under this operation can be higher than the fixed-frequency PWM operation through skipping switching cycles.

7.3.1.5 Error Amplifier

The buck converter of the TPS65320D-Q1 buck regulator has a transconductance amplifier acting as the error amplifier. The error amplifier compares the FB1 voltage to the lower of the internal soft-start (SS) voltage or the internal 0.8-V voltage reference. The transconductance (gm) of the error amplifier is 310 µS during normal operation. During the soft-start operation, the transconductance is a fraction of the normal operating gm. When the voltage of the voltage on the FB1 pin is below 0.8 V and the buck regulator is regulating using an internal SS voltage, the gm is 70 µS. For frequency compensation, external compensation components (capacitor with series resistor and an optional parallel capacitor) must be connected between the COMP pin and the GND pin.

7.3.1.6 Voltage Reference

The voltage reference system produces a precise ±2% voltage reference over temperature by scaling the output of a temperature stable band-gap circuit.

7.3.1.7 Adjusting the Output Voltage

A resistor divider from the output node to the FB1 pin sets the output voltage. TI recommends using 1% tolerance or better divider resistors. Start with 10 kΩ for the R2 resistor and use Equation 1 to calculate R1. To improve efficiency at light loads, consider using larger-value resistors. If the values are too high, the regulator is more susceptible to noise, and voltage errors from the FB1 input current are noticeable.

where

- VO = buck regulator output voltage

7.3.1.8 Soft-Start Pin (SS)

The TPS65320D-Q1 buck regulator regulates the output voltage by referencing the lower of either the internal voltage reference or the SS pin voltage. A capacitor on the SS pin to ground implements a soft-start time. The TPS65320D-Q1 buck regulator has an internal pullup current source of 2 μA that charges the external soft-start capacitor. Equation 2 shows the calculations for the soft-start time (10% to 90%). The voltage reference (Vref) is 0.8 V and the soft-start current (Iss) is 2 μA. The soft-start capacitor must remain lower than 10 nF and greater than 1 nF.

where

- The voltage reference (Vref) is 0.8 V.

- The soft-start current (ISS) is 2 µA.

To secure a smooth power up with effective soft-start, the delay between a shutdown event and a consecutive power-up event (such as recovering from a UVLO event or from a thermal shutdown event) must be long enough to allow a complete discharge of the soft-start capacitor. The soft-start capacitor is discharged through an internal FET when the buck is disabled (EN1 = low). Because the FET has a finite resistance, a minimum disable time is required to allow discharge of the capacitor. In either case, the buck must be disabled for at least 100 μs. For soft-start capacitance with values higher than 1.5 nF, the discharge time of the capacitor increases linearly as shown in Figure 8.

Figure 8. Soft-Start Capacitance Value versus Discharge Time

Figure 8. Soft-Start Capacitance Value versus Discharge Time

7.3.1.9 Overload-Recovery Circuit

The TPS65320D-Q1 buck regulator has an overload recovery (OLR) circuit. The OLR circuit soft-starts the output from the overload voltage to the nominal regulation voltage on removal of the fault condition. The OLR circuit discharges the SS pin to a voltage slightly greater than the FB1 pin voltage using an internal pulldown of 382 μA when the error amplifier changes to a high voltage from a fault condition. On removal of the fault condition, the output soft starts from the fault voltage to nominal output voltage.

7.3.1.10 Constant Switching Frequency and Timing Resistor (RT/CLK Pin)

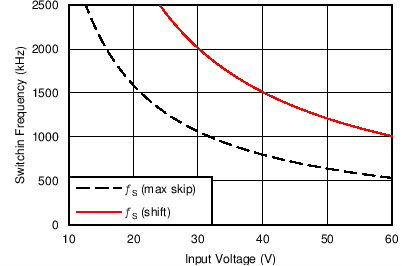

The switching frequency of the TPS65320D-Q1 buck regulator is adjustable over a wide range from approximately 100 kHz to 2500 kHz by placing a resistor on the RT/CLK pin. The RT/CLK pin voltage is 0.5 V (typical) and must have a resistor to ground to set the switching frequency. To determine the timing resistance for a given switching frequency, use Equation 3 or the curves in Figure 2. To reduce the solution size, the user typically sets the switching frequency as high as possible. However, consider tradeoffs of the supply efficiency, maximum input voltage, and minimum controllable on-time. The minimum controllable on-time is 100 ns (typical) and limits the maximum operating input voltage. The frequency-shift circuit also limits the maximum switching frequency. The following sections discuss more details of the maximum switching frequency.

7.3.1.11 Overcurrent Protection and Frequency Shift

The TPS65320D-Q1 buck regulator implements current-mode control, which uses the COMP pin voltage to turn off the high-side MOSFET on a cycle-by-cycle basis. During each cycle, the switch current and COMP pin voltage are compared. When the peak-switch current intersects the COMP voltage, the high-side switch turns off. During overcurrent conditions that pull the output voltage low, the error amplifier responds by driving the COMP pin high, increasing the switch current. Internal clamping of the error-amplifier output functions as a switch current-limit.

The TPS65320D-Q1 buck regulator also implements a frequency shift. The switching frequency is divided by 8, 4, 2, and 1 as the voltage ramps from 0 to 0.8 V on the FB1 pin. During short-circuit events (particularly with high-input-voltage applications), the control loop has a finite minimum controllable on-time, and the output has a low voltage. During the switch on-time, the inductor current ramps to the peak current-limit because of the high input voltage and minimum on-time. During the switch off-time, the inductor typically does not have enough off-time and output voltage for the inductor to ramp down by the ramp-up amount. The frequency shift effectively increases the off-time which allows the current to ramp down.

7.3.1.12 Selecting the Switching Frequency

The switching frequency that is selected must be the lower value of the two equations, Equation 4 and Equation 5. Equation 4 is the maximum switching-frequency limitation set by the minimum controllable on-time. Setting the switching frequency above this value causes the regulator to skip switching pulses. The device maintains regulation, but pulse-skipping leads to high inductor current and a significant increase in output ripple voltage.

Use Equation 5 to calculate the maximum switching frequency limit set by the frequency-shift protection. For adequate output short-circuit protection at high input voltages, set the switching frequency to a value less than the ƒS(maxshift) frequency. In Equation 5, to calculate the maximum switching frequency one must take into account that the output voltage decreases from the nominal voltage to 0 volts, and the ƒdiv integer increases from 1 to 8 corresponding to the frequency shift.

where

- IL = inductor current

- Rdc = inductor resistance

- VI = maximum input voltage

- VO = buck regulator output voltage

- Vd = diode voltage drop

- Rhs = FET on resistance (127 mΩ, trypical)

- ton = controllable on-time (100 ns, typical)

where

- VO(SC) = buck regulator output voltage during short-circuit condition

- ƒdiv = frequency divide factor (equals 1, 2, 4 or 8)

In Figure 9 the solid line illustrates a typical safe operating area regarding frequency shift and assumes the output voltage is 0 V, the resistance of the inductor is 0.13 Ω, the FET on-resistance is 0.127 Ω, and the diode voltage drop is 0.5 V. The dashed line is the maximum switching frequency to avoid pulse skipping.

| VO = 3.3 V | IL = 1 A |

7.3.1.13 How to Interface to RT/CLK Pin

The RT/CLK pin synchronizes the buck regulator to an external system clock. To implement the synchronization feature, connect a square wave to the RT/CLK pin through the circuit network shown in Figure 10. The square-wave amplitude must transition lower than 0.5 V and higher than 2.2 V on the RT/CLK pin and must have an on-time greater than 40 ns and an off-time greater than 40 ns. The synchronization frequency range is 300 kHz to 2200 kHz. The rising edge of the SW pin synchronizes with the falling edge of the RT/CLK pin signal. Design the external synchronization circuit in such a way that the device has the default frequency-set resistor connected from the RT/CLK pin to ground if the synchronization signal turns off. TI recommends using a frequency-set resistor connected as shown in Figure 10 through a 50-Ω resistor to ground. The resistor must set the switching frequency close to the external CLK frequency. TI also recommends AC-coupling the synchronization signal through a 10-pF ceramic capacitor to the RT/CLK pin and a 4-kΩ series resistor. The series resistor reduces SW jitter in heavy-load applications when synchronizing to an external clock, and in applications that transition from synchronizing to RT mode. The first time CLK is pulled above the CLK threshold, the device switches from the RT resistor frequency to PLL mode. Along with the resulting removal of the internal 0.5-V voltage source, the CLK pin becomes high-impedance as the PLL starts to lock onto the external signal. Because there is a PLL on the buck regulator, the switching frequency can be higher or lower than the frequency set with the external resistor. The buck regulator transitions from the resistor mode to the PLL mode and then increases or decreases the switching frequency until the PLL locks onto the CLK frequency within 100 ms.

When the buck regulator transitions from the PLL mode to the resistor mode, the switching frequency slows down from the CLK frequency to 150 kHz, then reapplies the 0.5-V voltage. The resistor then sets the switching frequency. The switching-frequency divisor changes to 8, 4, 2, and 1 as the voltage ramps from 0 to 0.8 V on the FB1 pin. The buck regulator implements a digital frequency shift to enable synchronizing to an external clock during standard start-up and fault conditions.

Figure 10. Synchronizing to a System Clock

Figure 10. Synchronizing to a System Clock

7.3.1.14 Overvoltage Transient Protection

The TPS65320D-Q1 buck regulator incorporates an overvoltage transient protection (OVTP) circuit to minimize voltage overshoot when recovering from output fault conditions or strong unload transients on power-supply designs with low-value output capacitance. For example, with the buck regulator output overloaded, the error amplifier compares the actual output voltage to the internal reference voltage. If the FB1 pin voltage is lower than the internal reference voltage for a considerable time, the output of the error amplifier responds by clamping the error amplifier output to a high voltage, thus requesting the maximum output current. On removal of the condition, the buck regulator output rises and the error-amplifier output transitions to the steady-state duty cycle. In some applications, the buck regulator output voltage can respond faster than the error-amplifier output can respond which leads to possible output overshoot. The OVTP feature minimizes the output overshoot when using a low-value output capacitor by implementing a circuit to compare the FB1-pin voltage to the OVTP threshold (which is 109% of the internal voltage reference). The FB1 pin voltage exceeding the OVTP threshold disables the high-side MOSFET, preventing current from flowing to the output and minimizing output overshoot. The FB1 voltage dropping lower than the OVTP threshold allows the high-side MOSFET to turn on at the next clock cycle.

7.3.1.15 Small-Signal Model for Loop Response

Figure 11 shows an equivalent model for the buck-regulator control loop which can be modeled in a circuit-simulation program to check frequency response and dynamic load response. The error amplifier is a transconductance amplifier with a gmea of 310 μS. Model the error amplifier using an ideal voltage-controlled current source. Resistor, RO, and capacitor, CO, model the open-loop gain and frequency response of the amplifier. The 1-mV AC-voltage source between nodes a and b effectively breaks the control loop for the frequency-response measurements. Plotting c versus a shows the small-signal response of the frequency compensation. Plotting a versus b shows the small-signal response of the overall loop. Check the dynamic loop response by replacing RL with a current source that has the appropriate load-step amplitude and step rate in a time-domain analysis. This equivalent model is only valid for continuous-conduction-mode designs.

Figure 11. Small-Signal Model for Loop Response

Figure 11. Small-Signal Model for Loop Response

7.3.1.16 Simple Small-Signal Model for Peak-Current Mode Control

Figure 12 shows a simple small-signal model that can be used to understand how to design the frequency compensation. A voltage-controlled current source (duty cycle modulator) supplying current to the output capacitor and load resistor can approximate the TPS65320D-Q1 buck regulator power stage. Equation 6 shows the control-to-output transfer function, which consists of a DC gain, one dominant pole, and one ESR zero. The quotient of the change in switch current divided by the change in COMP pin voltage (node c in Figure 11) is the power-stage transconductance. The gmps for the TPS65320D-Q1 buck regulator power-stage is 10.5 A/V. Use Equation 7 to calculate the low-frequency gain of the power stage which is the product of the transconductance and the load resistance.

As the load current increases and decreases, the low-frequency gain decreases and increases, respectively. This variation with the load seems problematic at first, but the dominant pole moves with the load current (see Equation 8). The dashed line in the right half of Figure 12 highlights the combined effect. As the load current decreases, the gain increases and the pole frequency lowers, keeping the 0-dB crossover frequency the same for the varying load conditions, which makes designing the frequency compensation easier. The type of output capacitor chosen determines whether the ESR zero has a profound effect on the frequency compensation design. Using high-ESR aluminum-electrolytic capacitors can reduce the number of frequency-compensation components required to stabilize the overall loop because the phase margin increases from the ESR zero at the lower frequencies (see Equation 9).

Figure 12. Simple Small-Signal Model and Frequency Response for Peak-Current Mode

Figure 12. Simple Small-Signal Model and Frequency Response for Peak-Current Mode

7.3.1.17 Small-Signal Model for Frequency Compensation

The buck regulator of the TPS65320D-Q1 device uses a transconductance amplifier as the error amplifier. Figure 13 shows compensation circuits. Implementation of Type 2 circuits is most likely in high-bandwidth power-supply designs. The purpose of loop compensation is to ensure stable operation while maximizing dynamic performance. Use of the Type 1 circuit is with power-supply designs that have high-ESR aluminum electrolytic or tantalum capacitors. Equation 10 and Equation 11 show how to relate the frequency response of the amplifier to the small-signal model in Figure 13. Modeling of the open-loop gain and bandwidth uses RO and CO shown in Figure 13. See the Typical Application section for a design example with a Type 2A network that has a low-ESR output capacitor. For stability purposes, the target must have a loop-gain slope that is –20 dB/decade at the crossover frequency. Also, the crossover frequency must not exceed one-fifth of the switching frequency (120 kHz in the case of a 600-kHz switching frequency).

For dynamic purposes, the higher the bandwidth, the faster the load-transient response. A large DC gain means high DC-regulation accuracy (DC voltage changes little with load or line variations). To achieve this loop gain, set the compensation components according to the shape of the control-output bode plot.

Equation 10 through Equation 20 serve as a reference to calculate the compensation components. RO and C1 form the dominant pole (P1). A resistor (R3) and a capacitor (C1) in series to ground work as zero (Z1). In addition, add a lower-value capacitor (C2) in parallel with R3 to work as an optional pole. This capacitor can filter noise at switching frequency, and is also required if the output capacitor has high ESR.

Figure 13. Types of Frequency Compensation

Figure 13. Types of Frequency Compensation

Figure 14. Frequency Response of the Type 2 Frequency Compensation

Figure 14. Frequency Response of the Type 2 Frequency Compensation

7.3.2 LDO Regulator

The LDO regulator on the TPS65320D-Q1 device can be used to supply low power consumption rails. The quiescent current in standby mode is about 35 µA under typical operating condition.

The LDO regulator require both supplies from VIN and VIN_LDO to function. At all times the voltage level of VIN must be higher or equal to the voltage level of VIN_LDO for the LDO regulator to function properly. The current capability of the LDO regulator is 280 mA under the full VIN_LDO input range, while V(VIN) ≥ 4 V. When VIN becomes less than 4 V, the current capability of the LDO regulator decreases.

7.3.2.1 Charge-Pump Operation

The LDO regulator has an internal charge-pump that turns on or off depending on the input voltage. The charge-pump switching circuitry does not cause conducted emissions to exceed required thresholds on the input voltage line. The charge-pump switching thresholds are hysteretic. Figure 15 shows the typical switching thresholds for the charge pump.

Figure 15. Charge-Pump Switching Thresholds

Figure 15. Charge-Pump Switching Thresholds

Table 1. Typical Quiescent Current Consumption

| CHARGE PUMP ON | CHARGE PUMP OFF | |

|---|---|---|

| LDO IQ | 300-µA | 35 µA |

7.3.2.2 Low-Voltage Tracking

At low input voltages, the regulator drops out of regulation, and the output voltage tracks input minus a drop out voltage (VDROPOUT). This feature allows for a smaller input capacitor and can possibly eliminate the need to use a boost convertor during cold-crank conditions.

7.3.2.3 Adjusting the Output Voltage

A resistor divider from the output node to the FB2 pin sets the output voltage. TI recommends using 1% tolerance or better divider resistors. Referring to the schematics in Figure 17, begin with 10 kΩ as the selected value for the R6 resistor and use Equation 21 to calculate the value of the R5 resistor.

To improve efficiency at light loads, consider using larger-value resistors. If the values are too high, the regulator is more susceptible to noise, and voltage errors from the FB2 input current are noticeable.

7.3.3 Thermal Shutdown

The device implements an internal thermal shutdown as protection if the junction temperature exceeds 170°C (typical). The thermal shutdown forces the buck regulator to stop switching and disables the LDO regulator when the junction temperature exceeds the thermal trip threshold. Once the junction temperature decreases below 160°C (typical), the device re-initiates the power-up sequence.

7.3.4 Power-Good Output, nRST

The nRST pin is a push-pull output formed by a push-pull stage between LDO_OUT and GND pins. The power-on-reset output asserts low until the output voltage on LDO_OUT exceeds the setting thresholds of 92% (typical) and the deglitch timer has expired. Additionally, whenever the EN2 pin is low or open, the nRST pin immediately asserts low regardless of the output voltage. If a thermal shutdown occurs because of excessive thermal conditions, this pin also asserts low.

7.3.5 Enable and Undervoltage Lockout

The TPS65320D-Q1 device enable pins (EN1 and EN2) are high-voltage-tolerant input pins with an internal pulldown circuit. A high input activates the device and turns on the regulators.

The TPS65320D-Q1 device has an internal UVLO circuit to shut down the output if the input voltage falls below an internally-fixed UVLO-falling threshold level. This UVLO circuit ensures that both regulators are not latched into an unknown state during low-input-voltage conditions. The regulators power up when the input voltage exceeds the UVLO-rising threshold level.

7.4 Device Functional Modes

7.4.1 Modes of Operation

The buck regulator has two hardware enable pins, and one can turn off either the buck or the LDO by pulling the enable pin low, as listed in Table 2. One unique feature of the TPS65320D-Q1 buck regulator is the input auto source of the LDO. With both the buck and the LDO enabled, the LDO receives input from the output of the buck through the VIN_LDO pin. In this mode, the buck output voltage must be higher than the LDO output voltage. With the buck disabled and the LDO still enabled, the input of the LDO changes automatically from VIN_LDO to VIN which is useful for standby operations which need a very low standby current, such as automotive infotainment, telematics, and other operations. The LDO changes the input when the buck output voltage is out of regulation (V(FB1) is less than 91% of Vref1).

Table 2. Device Operation Modes

| BUCK | LDO | DESCRIPTION |

|---|---|---|

| EN1 | EN2 | |

| 0 | 0 | Both buck and LDO disabled |

| 0 | 1 | Buck disabled. LDO enabled and LDO input source is from the battery. |

| 1 | 0 | Buck enabled and LDO disabled |

| 1 | 1 | Both buck and LDO enabled and LDO input source is from buck output. Buck output voltage must be higher than LDO output voltage. |

Figure 16. Example of LDO Auto Source in Standby Condition

Figure 16. Example of LDO Auto Source in Standby Condition