SLOS918A August 2015 – October 2015 TAS5404-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

パッケージ・オプション

メカニカル・データ(パッケージ|ピン)

- PHD|64

サーマルパッド・メカニカル・データ

- PHD|64

発注情報

12 Layout

12.1 Layout Guidelines

- The EVM layout optimizes for low noise and EMC performance.

- The TAS5404-Q1 device has a thermal pad up, so a the layout must take into account an external heatsink.

- Layout also affects EMC performance.

- The EVM PCB illustrations form the basis for the layout discussions.

12.2 Layout Example

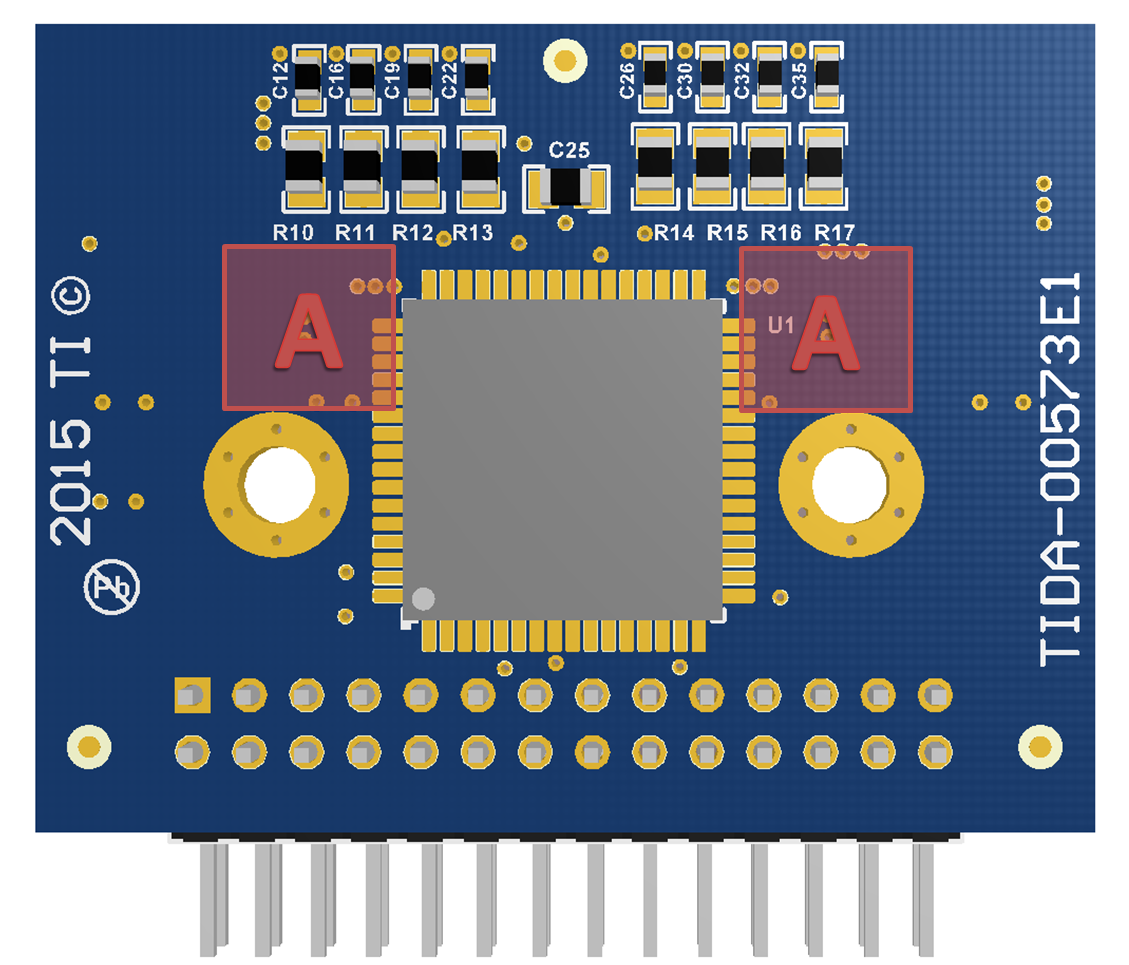

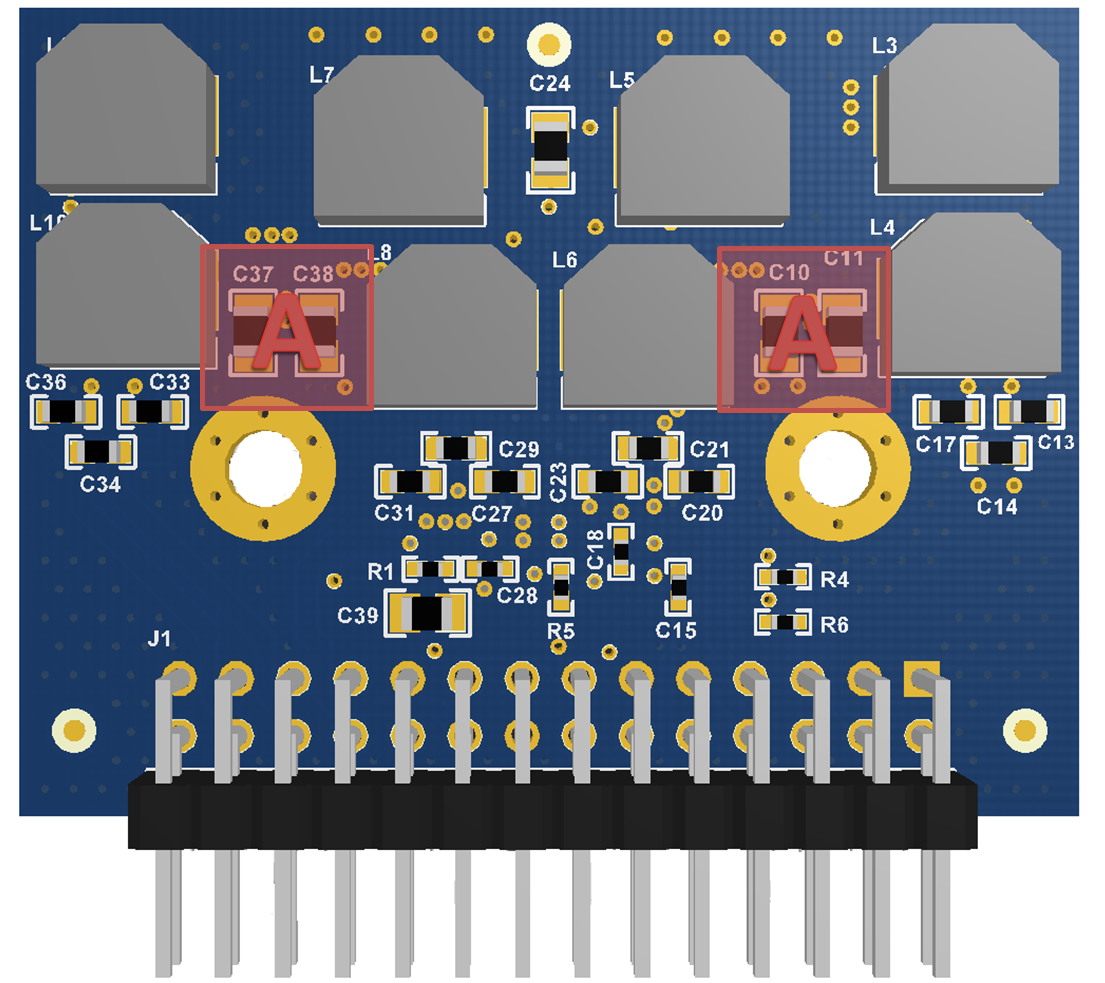

The areas in Figure 23 and Figure 24 indicated by the label "A", are critical to proper operation and EMC layout. The PVDD and ground-decoupling capacitors should be close to the TAS5404-Q1 device. These ground-decoupling capacitors must be on both groups of PVDD pins to ground. The ground connections of the snubber circuits must also be close to the grounds of the TAS5404-Q1 device.

Figure 23. TAS5404 Board Layout - Top View

Figure 23. TAS5404 Board Layout - Top View

Figure 24. TAS5404 Board Layout - Bottom View

Figure 24. TAS5404 Board Layout - Bottom View

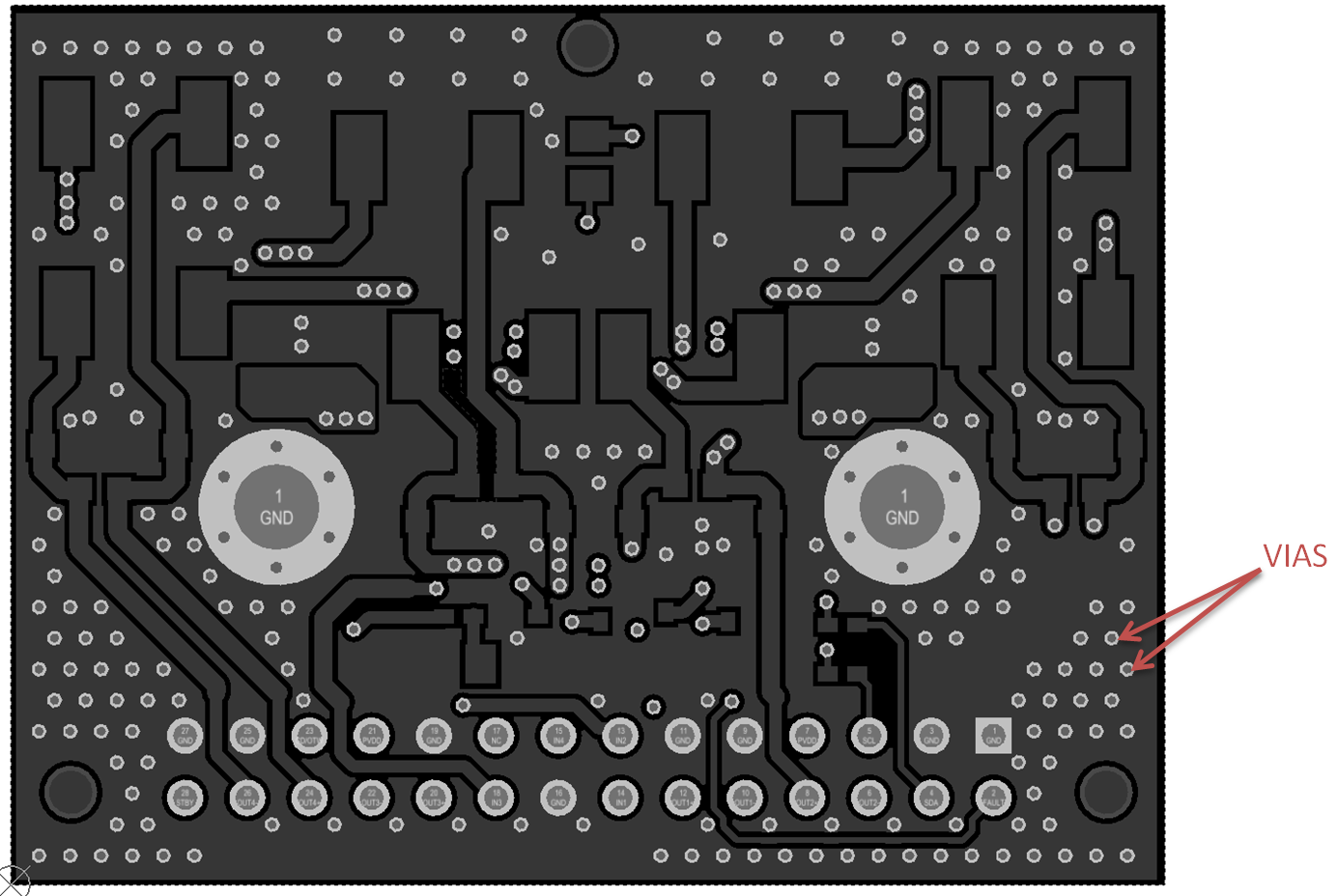

Each layer in the EVM contains a ground plane. All the ground planes should be connected together through many vias to reduce the impedance between the ground layers, which provides for low inductance paths for reduced EMI.

Figure 25. TAS5404 Board Layout - Bottom Layer

Figure 25. TAS5404 Board Layout - Bottom Layer

12.3 Thermal Consideration

The design of the thermally augmented package is to interface directly to heat sinks using a thermal interface compound (for example, Arctic Silver®, Ceramique thermal compound). The heat sink then absorbs heat from the ICs and couples it to the local air. With proper thermal management the process can reach equilibrium at a lower temperature, and heat can be continually removed from the ICs. Because of the efficiency of the TAS5404-Q1 device, heat sinks can be smaller than those required for linear amplifiers of equivalent performance.

RθJA is a system thermal resistance from junction to ambient air. As such, it is a system parameter with the following components:

- RθJC (the thermal resistance from junction to case, or in this case the heat slug)

- Thermal resistance of the thermal grease

- Thermal resistance of the heat sink

One can calculate the thermal resistance of the thermal grease from the exposed heat slug area and the manufacturer's value for the area thermal resistance of the thermal grease (expressed in °C-in2/W or °C-mm2/W). The area thermal resistance of the example thermal grease with a 0.001-inch (0.0254-mm) thick layer is about 0.007°C-in2/W (4.52°C-mm2/W). The approximate exposed heat slug size for a 64-pin QFP is 0.099 in2 (64 mm2)

Dividing the example area thermal resistance of the thermal grease by the area of the heat slug gives the actual resistance through the thermal grease for both parts, which is 0.07°C/W.

The thermal resistance of thermal pads is generally considerably higher than a thin thermal-grease layer. Thermal tape has an even higher thermal resistance and should not be used at all. The heat-sink vendor generally predicts heat sink thermal resistance, either modeled using a continuous-flow dynamics (CFD) model, or measured.

Therefore, for a single monaural channel in the IC, the system RθJA = RθJC + thermal-grease resistance + heat-sink resistance.

Table 25 indicates modeled parameters for one TAS5404-Q1 device on a heat sink. The exposed pad dimensions are 8 mm × 8 mm. The junction temperature setting is at 115°C while delivering 20 watts per channel into 4-Ω loads with no clipping. The assumed thickness of the thermal grease is about 0.001 inches (0.0254 mm).

Table 25. QFP Package Modeled Parameters

| DEVICE | 64-PIN QFP | UNIT |

|---|---|---|

| Ambient temperature | 25 | °C |

| Power to load | 20 | W × 4 |

| Power dissipation | 1.9 | W × 4 |

| ΔT inside package | 7.6 | °C |

| ΔT through thermal grease | 0.46 | °C |

| Required heatsink thermal resistance | 10.78 | °C/W |

| Junction temperature | 115 | °C |

| System RθJA | 11.85 | °C/W |

| RθJA × power dissipation | 90 | °C |

12.4 Electrical Connection of Heat Slug and Heat Sink

Electrically connect the heat sink attached to the heat slug of the TAS5404-Q1 device to GND, or leave it floating. Do not connect the heat slug to any other electrical node.

12.5 EMI Considerations

Automotive-level EMI performance depends on both careful integrated circuit design and good system-level design. Controlling sources of electromagnetic interference (EMI) was a major consideration in all aspects of the design.

The design has minimal parasitic inductances due to the short leads on the package. This dramatically reduces the EMI that results from current passing from the die to the system PCB. Each channel also operates at a different phase. The phase between channels is I2C selectable to either 45° or 180°, to reduce EMI caused by high-current switching. The design also incorporates circuitry that optimizes output transitions that cause EMI.