SLIA096 January 2022 DRV5021 , DRV5021-Q1 , DRV5023 , DRV5023-Q1 , DRV5032 , DRV5033 , DRV5033-Q1 , TMAG5123 , TMAG5123-Q1 , TMAG5124 , TMAG5124-Q1 , TMAG5131-Q1 , TMAG5231 , TMAG5328

2.8.3 Magnet Variation

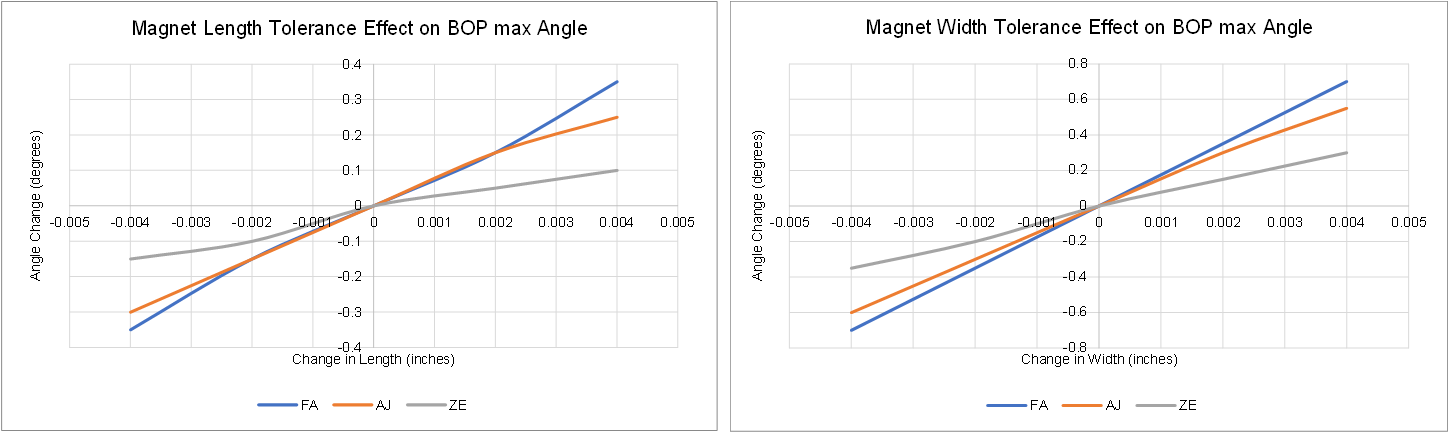

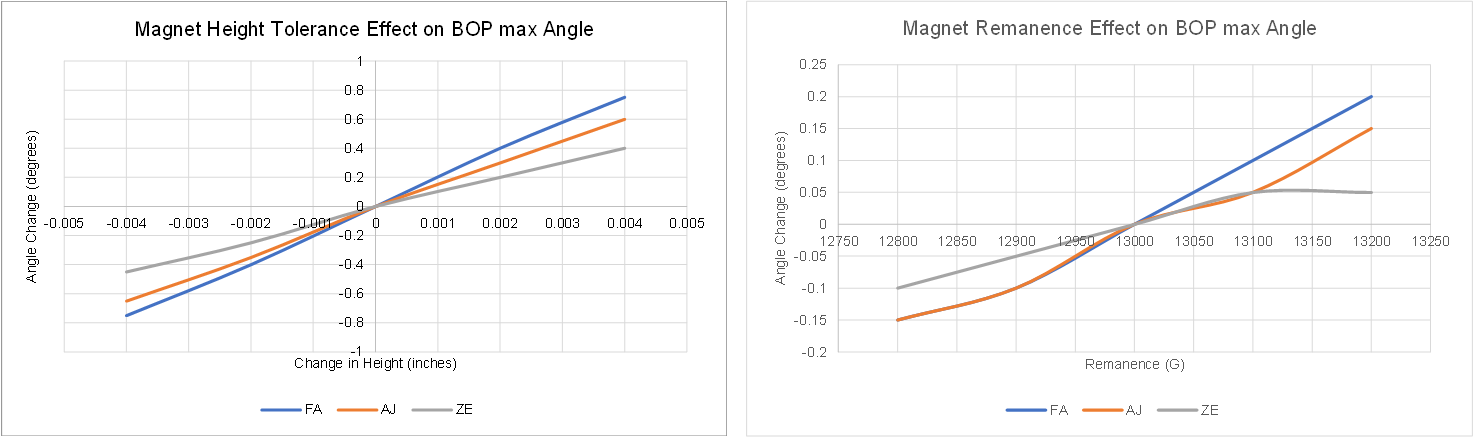

Magnet variation comprises physical dimensions as well as material composition. This design used a block shaped magnet and the relevant dimensions include magnet length, width, and thickness. Magnet composition can vary due to impurities, and the variation in composition corresponds to a range in remanence, Br, which directly relates to field strength.

The B221 magnet used in this document has a tolerance of ±0.004 inches for all dimensions. A typical N42 magnet like the B221 has Br of 13000 Gauss. Product specifications outlined a Br maximum of 13200 Gauss, thereby suggesting a possible tolerance of ±200 Gauss.

Figure 2-29 and Figure 2-30 show how much the BOP maximum angle can change with respect to the magnet variation.

Figure 2-29 Length and Width Tolerance

Impact on BOP Maximum Angle

Figure 2-29 Length and Width Tolerance

Impact on BOP Maximum Angle Figure 2-30 Height and Remanence Tolerance

Impact on BOP Maximum Angle

Figure 2-30 Height and Remanence Tolerance

Impact on BOP Maximum Angle