SLUUCV8 October 2023 TPS4810-Q1

3.1.4 Input Reverse Polarity Test

Use the following instructions to test the input reverse polarity protection:

- Set the jumper setting on EVM to default position as shown in Table 4-1.

- Set the input supply voltage VIN to 60 V and current limit of 10 A.

- Connect the power supply positive to T4 and power supply negative to T1. The power supply is now connected in reverse polarity at the input of TPS48100-Q1.

- Enable the power supply.

- Observe the waveform at VOUT (TP2) with an oscilloscope.

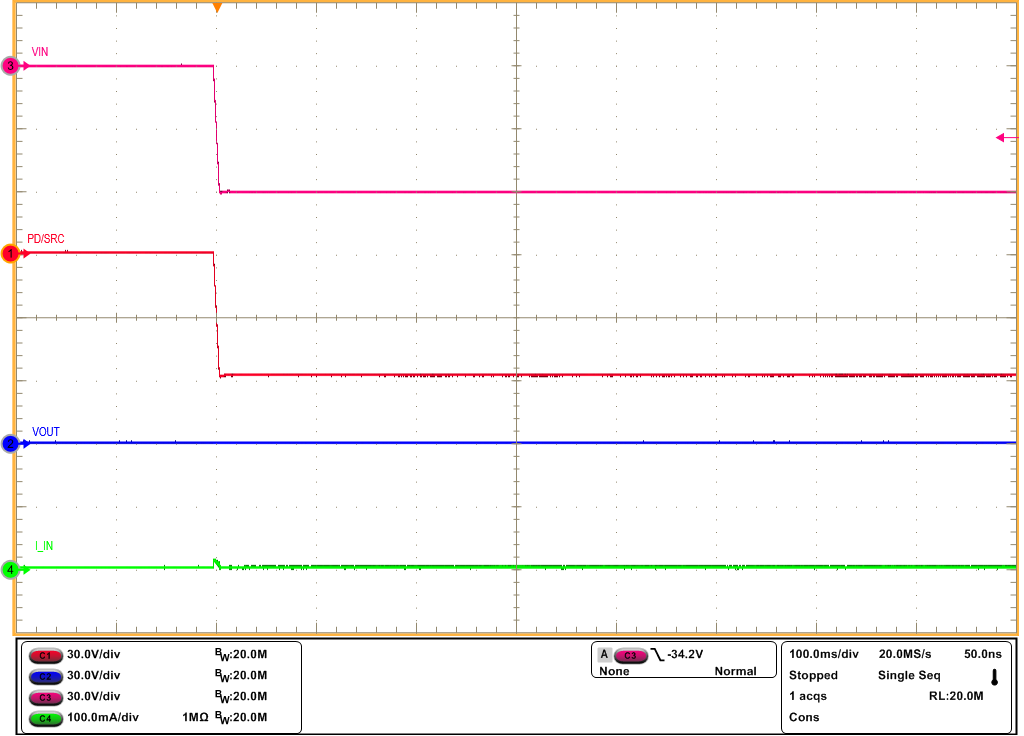

Figure 4-9 shows input reverse polarity protection of TPS48100-Q1 on TPS4810Q1EVM Evaluation Board.

Figure 3-9 Input Reverse Polarity Protection of TPS48100-Q1 Device

Figure 3-9 Input Reverse Polarity Protection of TPS48100-Q1 Device