SNOA951 June 2016 LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1

- Inductive Sensing Touch-On-Metal Buttons Design Guide

3.1 Mechanical System Design

This aspect of the system design is used to address the physical interface presented to the user. Considerations such as the number of buttons, the size and shape of the buttons, and material composition all need to be determined.

A typical home appliance example with a ToM control panel might have two or more adjacent buttons. For ease of use, the buttons should not be too small; typical applications may use 20-mm diameter buttons, which is sufficiently large for easy actuation. Typically the button panel is a flat metal surface constructed from a single sheet of metal. ToM buttons may use a wide variety of metals, but many consumer and industrial systems prefer stainless steel or aluminum surfaces which are commonly available materials.

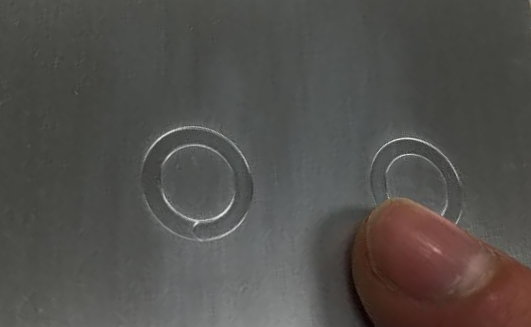

Indicating the location of the button can be handled with a wide range of approaches – from adhesive overlays, to painted markings, or even putting grooves or patterning onto the surface of the metal. Figure 4 shows an example button panel which has been produced from a 0.8-mm thick sheet of Aluminum Al6061-T6 – the buttons are clearly identified by the circular grooves.

Figure 4. Manufactured Button Panel

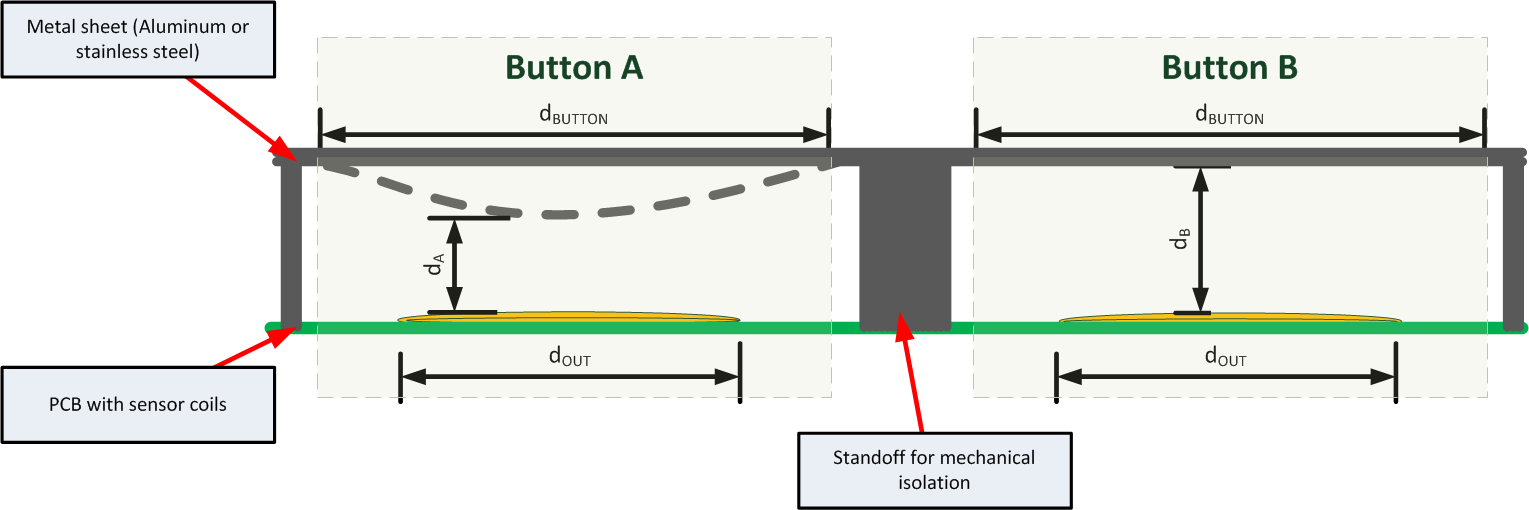

Figure 4. Manufactured Button Panel Figure 5 shows a side view of the two adjacent buttons in this example application.

Figure 5. Using Adjacent Buttons

Figure 5. Using Adjacent Buttons When a light force is applied onto button A, the inner surface of the metal sheet will be pushed towards the PCB sensors. This deflection causes a frequency shift in the LC sensor and must be enough to be easily detected by the LDC and then interpreted as a button press by the MCU in the system.

Sources of error, such as adjacent button deflection or other environmental noises, could mask the desired response and make it difficult for the MCU to distinguish the real button press. It is recommended that the desired amount of deflection for a button detection event should produce a response that is greater than the noise of the system by a factor of 10. For example, if the system noise appears like ±0.5-µm movement, then a button needs to move at least 5µm to be easily detected.

There are number of factors that influence how much metal deflection is produced by a button press, such as metal material and thickness. With good system design, the deflection of the metal for a typical button press is around 20 to 50 µm.