SSZT888 November 2017 LM5150-Q1

The start-stop system in hybrid electric vehicles (HEVs) helps reduce fuel consumption and emissions by stopping the engine during idling, but the battery voltage drops whenever the engine restarts. To provide the minimum required voltage to the loads during the battery voltage drop, pre-boost converters are widely used in automobiles.

Table 1 shows the typical requirements for a pre-boost converter.

Table 1 Pre-boost Converter

Specifications

| Requirements | |

|---|---|

| Input voltage | Peak 40V, typical 12V, minimum 2.5V |

| Output voltage | Maximum 40V, minimum 8.5V |

| Output current | From 2A to 4A |

In this blog post, I’ll explain the key parameters which affect the output-voltage undershoot of the pre-boost converter when the battery voltage drops.

Small-signal Analysis

Table 2 Factors That Improve the Loop Response and Lower the Output Impedance

| Key parameters | Factors for performance improvement |

|---|---|

| Fast loop response |

|

| Low output impedance |

|

Large-signal Analysis

Error Amplifier to PWM Comparator Offset

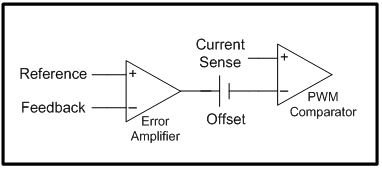

Figure 1 Controller Block of a Boost Device

Figure 1 Controller Block of a Boost DeviceError Amplifier Sourcing Capability

Wake-up Delay

LM5150-Q1 Automotive Boost Controller

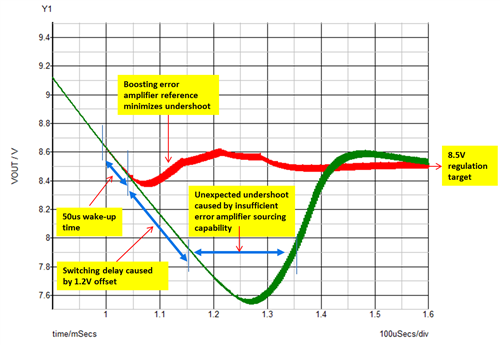

Figure 2 Pre-boost Output Voltage During Battery Voltage Drop (a Traditional Boost Converter Shown in Green, the LM5150-Q1 Shown in Red)

Figure 2 Pre-boost Output Voltage During Battery Voltage Drop (a Traditional Boost Converter Shown in Green, the LM5150-Q1 Shown in Red)Conclusion

Additional Resources

- Start a design now with the LM5150-Q1 in the WEBENCH® Design Center.

- Download the LM5150-Q1 simulation model.

- Watch the video, “How to Power Automotive Front-End Systems, Pre-Boost Solution.”

- Jumpstart your design today with the Automotive Pre-Boost Reference Design with 10.5V @ 3.0A.

- Learn more about TI’s hybrid/electric power train systems.